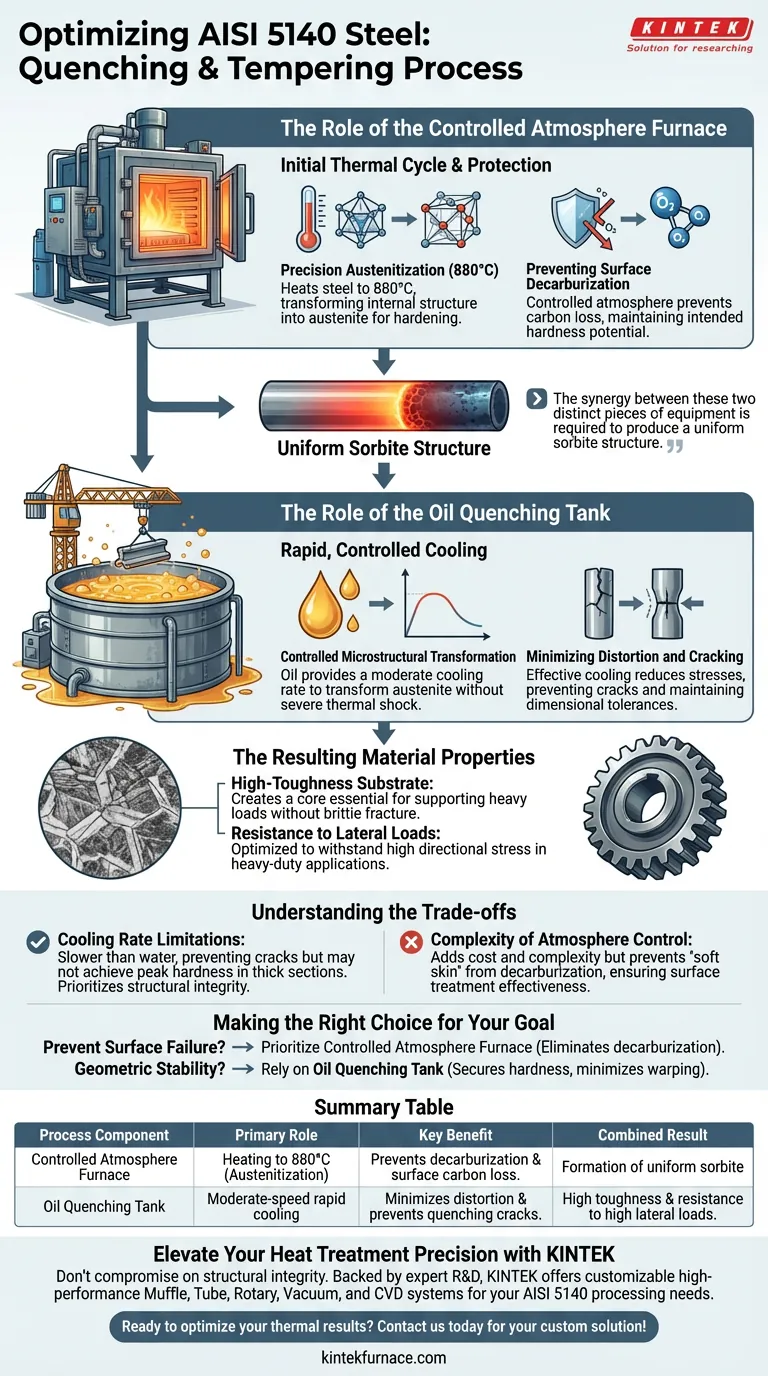

A controlled atmosphere furnace and an oil quenching tank work in tandem to optimize the mechanical core of AISI 5140 steel. The furnace ensures precise heating to 880°C without chemically damaging the surface, while the oil tank provides a controlled cooling rate to lock in a durable microstructure without inducing fractures.

The synergy between these two distinct pieces of equipment is required to produce a uniform sorbite structure. This specific microstructure delivers the high toughness necessary to withstand lateral loads and serves as a reliable substrate for subsequent surface hardening treatments.

The Role of the Controlled Atmosphere Furnace

The furnace is responsible for the initial thermal cycle, preparing the steel's internal structure while protecting its exterior.

Precision Austenitization

The primary function of the furnace is to heat the AISI 5140 steel to an austenitizing temperature of 880°C.

At this specific temperature, the internal crystal structure of the steel transforms into austenite. This phase change is the critical first step required before any hardening can occur.

Preventing Surface Decarburization

Standard furnaces allow oxygen to react with the steel surface, leading to decarburization (carbon loss).

The controlled atmosphere prevents this chemical reaction. By maintaining carbon levels at the surface, the furnace ensures the material retains its intended hardness potential and fatigue strength.

The Role of the Oil Quenching Tank

Once heated, the steel must be cooled rapidly but carefully. The industrial oil quenching tank manages this transformation.

Controlled Microstructural Transformation

The tank facilitates rapid cooling to transform the austenite into a harder structure.

While water is faster, oil provides a moderate cooling rate. This is aggressive enough to harden AISI 5140 but gentle enough to prevent the severe thermal shock often associated with water quenching.

Minimizing Distortion and Cracking

Rapid cooling introduces significant internal stress.

By using oil, the process effectively reduces cooling stresses. This helps prevent the formation of quenching cracks and minimizes distortion, ensuring the part maintains its dimensional tolerances.

The Resulting Material Properties

The combined operation of this equipment yields specific mechanical advantages defined by the "uniform sorbite" structure.

High-Toughness Substrate

The process creates a core that is tough rather than brittle.

This high-toughness substrate is essential for parts that must support heavy loads without snapping. It provides the necessary "backbone" for components that will later undergo surface hardening.

Resistance to Lateral Loads

The resulting microstructure is specifically optimized to handle directional stress.

Parts treated in this manner can withstand high lateral loads without brittle fracture, making them suitable for heavy-duty mechanical applications.

Understanding the Trade-offs

While this equipment combination is optimal for AISI 5140, it introduces specific operational considerations.

Cooling Rate Limitations

Oil quenching is slower than water quenching.

While this prevents cracking, it may not achieve maximum theoretical hardness in thicker sections compared to more aggressive media. The trade-off is accepted to prioritize structural integrity over absolute peak hardness.

Complexity of Atmosphere Control

Maintaining a controlled atmosphere adds cost and complexity compared to open-air heating.

However, omitting this step risks a "soft skin" on the part due to decarburization, which would compromise the effectiveness of any future surface treatments.

Making the Right Choice for Your Goal

To ensure your heat treatment process meets your engineering requirements, consider the following specific objectives:

- If your primary focus is preventing surface failure: Prioritize the controlled atmosphere furnace to eliminate decarburization and ensure a pristine surface for hardening.

- If your primary focus is geometric stability: Rely on the oil quenching tank to provide a cooling rate that secures hardness while minimizing the risk of warping or cracking.

By strictly controlling both the heating environment and the cooling medium, you transform AISI 5140 from a raw material into a component capable of enduring high-stress environments.

Summary Table:

| Process Component | Primary Role for AISI 5140 | Key Benefit |

|---|---|---|

| Controlled Atmosphere Furnace | Heating to 880°C (Austenitization) | Prevents decarburization and surface carbon loss. |

| Oil Quenching Tank | Moderate-speed rapid cooling | Minimizes distortion and prevents quenching cracks. |

| Combined Result | Formation of uniform sorbite | High toughness and resistance to high lateral loads. |

Elevate Your Heat Treatment Precision with KINTEK

Don’t compromise on structural integrity. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all customizable to your specific AISI 5140 processing needs.

Whether you need to eliminate surface decarburization or master the cooling curve, our engineering team is ready to help you achieve the perfect microstructure.

Ready to optimize your thermal results? Contact us today to find your custom solution!

Visual Guide

References

- Talha İkbal Çığır, Mustafa Acarer. Comparison of Surface Hardening Processes Applied to AISI 5140 Steel withSide Load Test. DOI: 10.30939/ijastech..1370591

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What role does an industrial-grade atmospheric furnace play in fire simulation tests? Master ASTM Safety Standards

- What is the function of a tube atmosphere furnace? Precision Mn1/CeO2 Catalyst Reduction & Fabrication

- What are the primary purposes of a controlled atmosphere furnace? Achieve Precise Material Processing and Protection

- How does the heating mechanism differ between a muffle furnace and an atmosphere furnace? Discover Key Design and Application Insights

- What challenges are associated with using inert atmospheres? Overcome Costs, Safety, and Complexity

- How does an atmosphere box furnace contribute to material heat treatment? Achieve Precise Control and Superior Results

- How is a controlled atmosphere furnace used in material research? Achieve Precise Material Synthesis and Heat Treatment