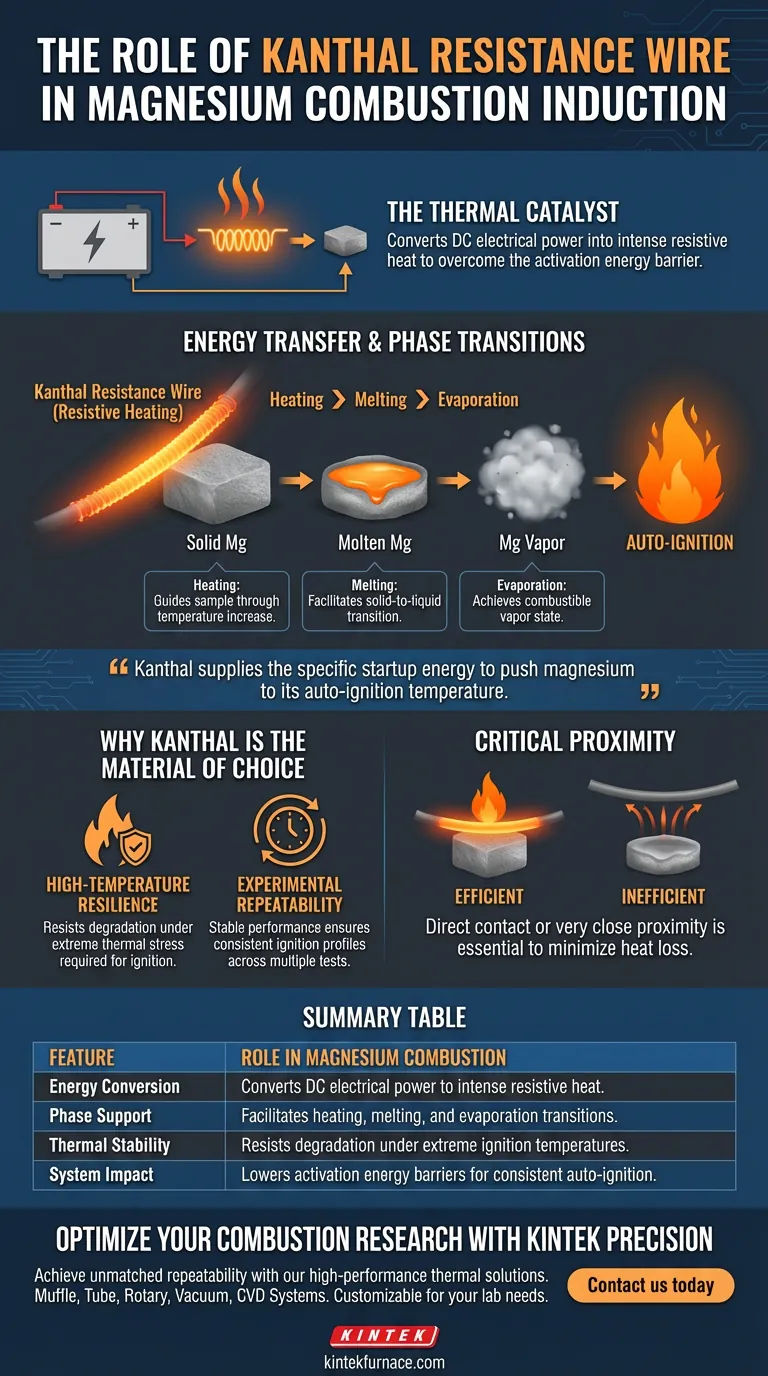

Kanthal resistance wire acts as the critical thermal catalyst during the induction phase of magnesium combustion. Functioning as the core of the ignition system, it converts DC electrical power into intense resistive heat to overcome the activation energy barrier. This wire is positioned in direct contact with or in close proximity to the magnesium sample to drive the material through the necessary physical changes required to sustain a flame.

The Kanthal wire does not merely heat the sample; it supplies the specific startup energy required to push magnesium through heating, melting, and evaporation until it reaches its auto-ignition temperature.

The Mechanism of Energy Transfer

Conversion of Electrical Energy

The system utilizes a DC power supply to drive current through the Kanthal wire.

Because Kanthal is a resistance alloy, this electrical flow is efficiently converted into thermal energy via resistive heating.

Driving Phase Transitions

Magnesium requires significant energy input to transition from a solid state to a combustible vapor.

The heat generated by the wire guides the sample through three distinct stages: heating, melting, and evaporation.

It is only after the magnesium evaporates that it reaches the necessary condition for ignition, a process fully supported by the wire's thermal output.

Why Kanthal is the Material of Choice

High-Temperature Resilience

Ignition systems operate under extreme thermal stress.

Kanthal is selected for its excellent high-temperature resistance, allowing it to generate the required heat without degrading before the magnesium ignites.

Ensuring Experimental Repeatability

In combustion research, consistency is paramount.

The performance stability of Kanthal wire ensures that the heat profile remains consistent across multiple tests.

This stability guarantees that the ignition process is repeatable, minimizing variables in the data caused by equipment fluctuation.

Critical Operational Considerations

The Importance of Proximity

For the induction phase to be successful, energy transfer must be efficient.

The reference emphasizes that the wire must be in direct contact or very close proximity to the magnesium.

Poor positioning can lead to insufficient heat transfer, preventing the sample from reaching the evaporation stage required for ignition.

Making the Right Choice for Your Goal

To optimize your magnesium combustion setup, consider the following based on your specific objectives:

- If your primary focus is data consistency: Prioritize the use of Kanthal wire due to its high stability, which ensures the ignition curve remains identical across repeated experiments.

- If your primary focus is ignition efficiency: Ensure the physical setup allows for direct contact between the wire and the sample to minimize heat loss during the heating and melting phases.

By leveraging the thermal stability of Kanthal wire, you ensure a controlled and reliable transition from solid metal to sustained combustion.

Summary Table:

| Feature | Role in Magnesium Combustion |

|---|---|

| Energy Conversion | Converts DC electrical power into intense resistive heat |

| Phase Support | Facilitates heating, melting, and evaporation transitions |

| Thermal Stability | Resists degradation under extreme ignition temperatures |

| System Impact | Lowers activation energy barriers for consistent auto-ignition |

Optimize Your Combustion Research with KINTEK Precision

Achieve unmatched experimental repeatability with high-performance thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to meet your unique magnesium combustion or material science needs.

Ready to elevate your lab’s efficiency? Contact us today to discuss how our specialized heating technology can support your next breakthrough.

Visual Guide

References

- Ioan Barabulica, Ioan Mămăligă. Experimental Study on the Reaction of Magnesium in Carbon Dioxide and Nitrogen Atmosphere. DOI: 10.3390/chemengineering8020041

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How do silicon carbide heating elements enhance the heat treatment of alloys? Achieve Superior Temperature Control

- What are the physical properties of molybdenum disilicide? Discover Its High-Temp Performance

- What are the advantages of using SiC heating elements in sintering furnaces? Boost Efficiency and Versatility

- How does graphite behave under high temperatures compared to other materials? Discover Its Unique Strengths

- What are the safety considerations when working with silicon carbide heating elements? Ensure Safe Operation in High-Temp Labs

- What are the models of MoSi2 heating elements and their working temperatures? Choose the Right Model for Your High-Temp Needs

- Why are industrial K-type thermocouples and mobile data loggers essential? Unlock Precise Quenching Accuracy

- What is the purpose of wrapping heating tapes around AP-SCVD gas lines? Prevent Condensation for Perfect Film Quality