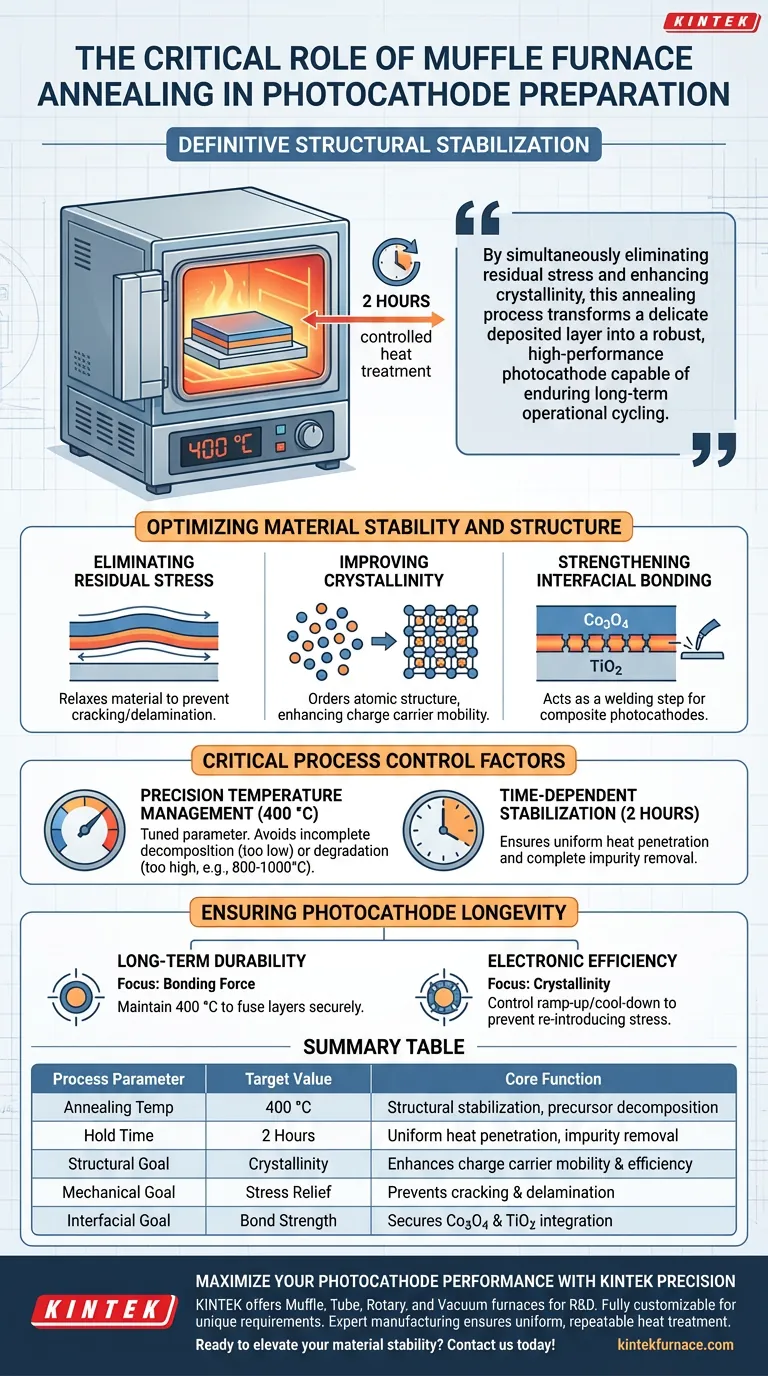

Annealing in a Muffle furnace serves as the definitive structural stabilization step in the final preparation of photocathodes. Specifically, this process involves subjecting the material to a controlled heat treatment at 400 °C for 2 hours. This thermal stage is essential for relieving internal mechanical stresses and solidifying the interface between deposited layers, directly dictating the component's future reliability.

By simultaneous eliminating residual stress and enhancing crystallinity, this annealing process transforms a delicate deposited layer into a robust, high-performance photocathode capable of enduring long-term operational cycling.

Optimizing Material Stability and Structure

The primary function of the Muffle furnace in this context is to transition the material from a raw deposited state to a stable, crystalline structure. This heat treatment addresses three specific physical requirements.

Eliminating Residual Stress

During the initial deposition of material layers, significant residual stress can accumulate within the structure.

If left untreated, this internal tension creates weak points that lead to mechanical failure. The annealing process relaxes the material, effectively removing these stresses to prevent future cracking or delamination.

Improving Crystallinity

Heat treatment is the primary driver for ordering the atomic structure of the active substances.

Holding the temperature at 400 °C allows atoms to settle into a more regular, crystalline lattice. High crystallinity is vital for semiconductor performance, as it typically correlates with improved charge carrier mobility and overall efficiency.

Strengthening Interfacial Bonding

For composite photocathodes, such as those combining Co3O4 and TiO2, the interface between materials is a common failure point.

Annealing acts as a welding step, significantly strengthening the bonding force between these distinct layers. This ensures the structural integrity of the device, preventing the layers from separating during the stress of chemical reactions.

Critical Process Control Factors

While annealing is beneficial, it requires strict adherence to specific parameters to avoid diminishing returns or material damage.

Precision Temperature Management

The specific protocol of 400 °C is not arbitrary; it is a tuned parameter for this specific material set.

Temperatures that are too low may fail to fully decompose precursors or achieve the necessary crystalline phase. Conversely, excessive temperatures (common in other furnace applications like sintering at 800°C or silicon annealing at 1000°C) could degrade the active oxides or damage the substrate.

Time-Dependent Stabilization

The duration of 2 hours is critical for ensuring the heat permeates the entire mass uniformly.

This duration allows sufficient time for the complete removal of any remaining volatile impurities and ensures that the structural changes are uniform throughout the depth of the photocathode, not just on the surface.

Ensuring Photocathode Longevity

To maximize the utility of your Muffle furnace annealing process, you must align your thermal profile with your specific performance goals.

- If your primary focus is Long-Term Durability: Prioritize the bonding force by strictly maintaining the 400 °C setpoint to ensure the Co3O4 and TiO2 layers fuse securely without degradation.

- If your primary focus is Electronic Efficiency: Focus on the crystallinity aspect by ensuring the ramp-up and cool-down rates are controlled to prevent re-introducing stress into the lattice.

Precision in this final thermal step is what ultimately separates a functioning experimental sample from a viable, robust component.

Summary Table:

| Process Parameter | Target Value | Core Function |

|---|---|---|

| Annealing Temp | 400 °C | Structural stabilization and precursor decomposition |

| Hold Time | 2 Hours | Uniform heat penetration and impurity removal |

| Structural Goal | Crystallinity | Enhances charge carrier mobility and efficiency |

| Mechanical Goal | Stress Relief | Prevents cracking and delamination of layers |

| Interfacial Goal | Bond Strength | Secures Co3O4 and TiO2 layer integration |

Maximize Your Photocathode Performance with KINTEK Precision

Achieving the perfect 400 °C annealing profile requires the thermal accuracy that only professional-grade equipment can provide. KINTEK offers a comprehensive range of Muffle, Tube, Rotary, and Vacuum furnaces, specifically engineered for materials science and R&D applications.

Whether you are refining composite layers like Co3O4/TiO2 or developing next-generation semiconductors, our systems are fully customizable to meet your unique temperature and atmospheric requirements. Backed by expert manufacturing, KINTEK ensures your heat treatment is uniform, repeatable, and optimized for structural integrity.

Ready to elevate your material stability? Contact us today to discuss your laboratory needs!

Visual Guide

References

- Solar Trap‐Adsorption Photocathode for Highly Stable 2.4 V Dual‐Ion Solid‐State Iodine Batteries. DOI: 10.1002/adma.202504492

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What types of workpieces are suitable for box type high-temperature resistance furnaces? Versatile Solutions for Metals, Ceramics, and More

- How does a Muffle furnace facilitate the single-step zone melting process? Precision for Bismuth Telluride Alloys

- What is the role of a muffle furnace in the preparation of bulk graphitic carbon nitride (BCN)? Master BCN Synthesis

- What are the key design features of box furnaces? Discover High-Performance, Safe Thermal Processing

- What are the safety precautions when using a box type electric furnace? Ensure Operator and Equipment Protection

- What function does a muffle furnace serve in LaMO3 calcination? Master Perovskite Nanoparticle Synthesis

- How do box type resistance furnaces contribute to catalytic material preparation? Unlock Precision in Catalyst Synthesis

- What is the purpose of the muffle furnace? Achieve Pure, High-Temperature Processing