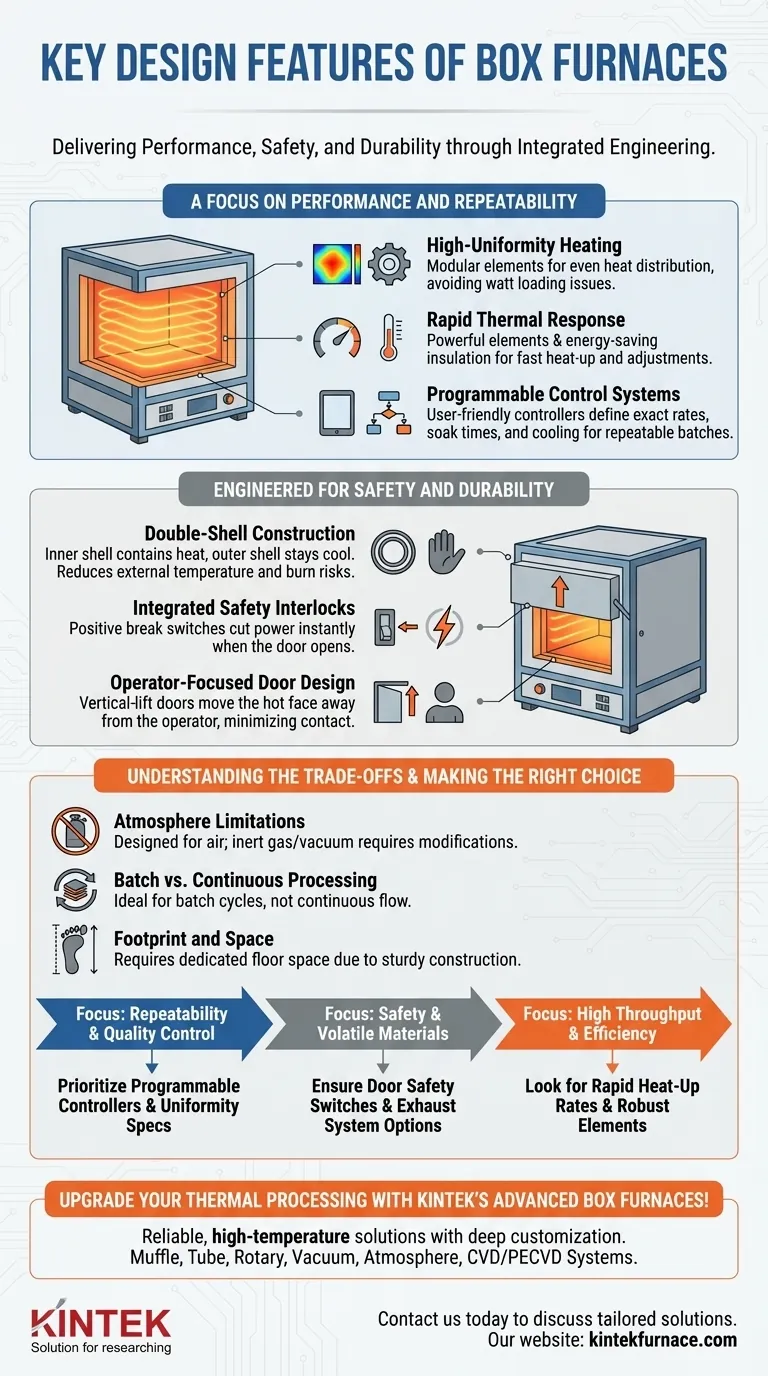

At their core, the key design features of a box furnace center on delivering performance, safety, and durability through integrated engineering. These furnaces are characterized by a double-shell construction to keep exterior surfaces cool, advanced heating elements for rapid and uniform temperature, and safety interlocks that protect the operator. The combination of these features creates a reliable tool for repeatable thermal processing.

A box furnace is not just a simple heated chamber; it is an engineered system designed for precise process control. Its key features work in concert to deliver consistent thermal results while ensuring operator safety and maximizing energy efficiency.

A Focus on Performance and Repeatability

The primary goal of any furnace is to deliver heat reliably. Box furnaces are specifically engineered to ensure that this heat delivery is both fast and exceptionally uniform, which is critical for process repeatability.

High-Uniformity Heating

The quality of a thermal process depends on every part of the load experiencing the same temperature. Box furnaces achieve this with modular plate heating elements known for their longevity and ability to distribute heat evenly.

This design avoids the limitations of "watt loading" seen in simpler furnaces, ensuring consistent temperatures throughout the chamber.

Rapid Thermal Response

Efficiency in a lab or production environment often depends on cycle time. Box furnaces are designed with powerful heating elements and effective, energy-saving insulation.

This combination allows for rapid heat-up rates and responsive temperature adjustments, minimizing downtime between processes.

Programmable Control Systems

Repeatability is impossible without precise control. Modern box furnaces feature user-friendly, fully programmable controllers.

These systems allow operators to define exact heating rates, soak times, and cooling rates, ensuring that every batch is processed under identical conditions.

Engineered for Safety and Durability

Handling high temperatures demands a robust approach to safety. The design of a box furnace incorporates multiple features to protect both the operator and the equipment itself.

Double-Shell Construction

A key safety and efficiency feature is the double-shell construction. An inner shell contains the heat, while an outer shell remains cool to the touch.

This design drastically reduces external surface temperatures, protecting operators from burns and lowering the heat load on the surrounding room.

Integrated Safety Interlocks

To prevent exposure to extreme temperatures, box furnaces are equipped with positive break safety switches.

These switches automatically cut power to the heating elements the moment the door is opened, providing a critical layer of operator protection.

Operator-Focused Door Design

The door itself is a safety component. Many box furnaces use a vertical-lift or swing-out door.

A vertical-lift door moves the hot inner face away from the operator when opened, minimizing the risk of accidental contact.

Fume and Exhaust Management

When processes involve materials that release fumes or volatile gases, proper ventilation is non-negotiable.

Many box furnaces can be equipped with fume hoods or local exhaust systems to safely manage off-gassing, ensuring compliance and a safe working environment.

Understanding the Trade-offs

While highly capable, box furnaces are not the universal solution for every heating application. Understanding their inherent trade-offs is crucial for making an informed decision.

Atmosphere Limitations

A standard box furnace is designed to operate in an air atmosphere. Achieving a controlled inert gas or vacuum environment requires significant modification or a different type of furnace altogether.

Batch vs. Continuous Processing

By their nature, box furnaces are designed for batch processing. They are ideal for loading a set of parts, running a cycle, and unloading. They are not suitable for continuous-flow manufacturing operations where parts move through a heated zone.

Footprint and Space

The sturdy, double-shell construction results in a considerable physical footprint. These are not small benchtop devices (though smaller models exist) and require dedicated floor space and power infrastructure.

Making the Right Choice for Your Application

Selecting the right furnace means matching its features to your primary operational goal.

- If your primary focus is process repeatability and quality control: Prioritize furnaces with highly programmable controllers and documented temperature uniformity specifications.

- If your primary focus is operator safety and handling volatile materials: Ensure the model includes a door safety switch and has available options for integrated exhaust systems.

- If your primary focus is high throughput and efficiency: Look for designs with rapid heat-up rates, superior insulation, and robust heating elements designed for longevity.

Ultimately, understanding these core design features allows you to select a furnace that functions not just as a tool, but as a reliable partner in your thermal processing work.

Summary Table:

| Feature Category | Key Design Features | Benefits |

|---|---|---|

| Performance & Repeatability | High-uniformity heating, Rapid thermal response, Programmable control systems | Ensures consistent results, fast cycle times, and precise process control |

| Safety & Durability | Double-shell construction, Safety interlocks, Operator-focused door design, Fume management | Protects operators, reduces heat loss, and ensures safe handling of volatile materials |

| Trade-offs | Atmosphere limitations, Batch processing, Larger footprint | Highlights constraints for informed decision-making in specific applications |

Upgrade your thermal processing with KINTEK's advanced box furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable, high-temperature solutions. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored furnace solutions can boost your efficiency and safety!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What morphological changes occur in POMOF after treatment? Unlock High Catalytic Performance via Thermal Evolution

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the core function of a muffle furnace in mesoporous silica prep? Master Template Removal & Calcination

- What functions does a high-temperature muffle furnace perform during cathode precursor processing?