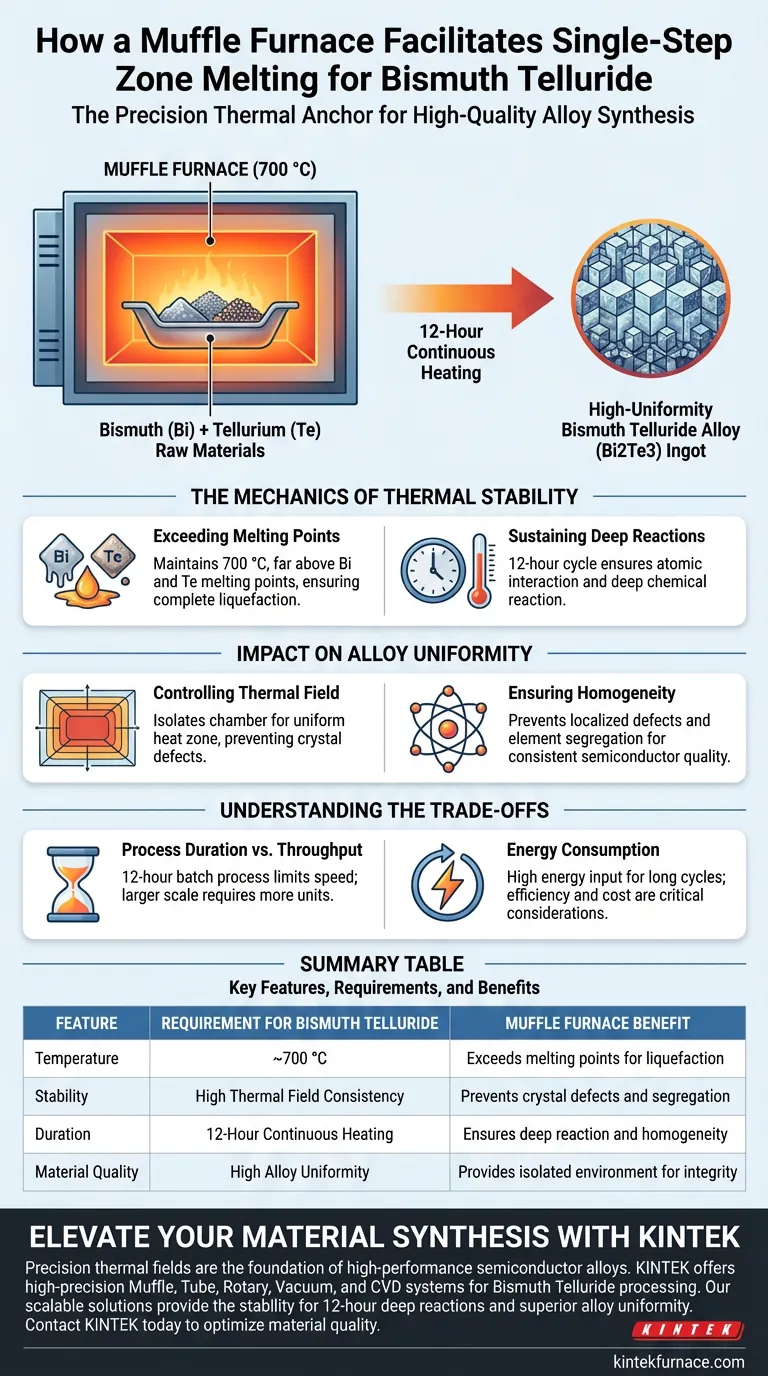

A Muffle furnace acts as the precision thermal anchor required to successfully execute the single-step zone melting process for Bismuth Telluride. It facilitates this by generating and maintaining a highly stable environment at approximately 700 °C, ensuring the complete liquefaction of reactants and allowing for a deep, uniform chemical reaction over extended periods, often lasting up to 12 hours.

The Muffle furnace’s ability to provide unwavering thermal field stability is the fundamental requirement for transforming raw Bismuth and Tellurium into high-uniformity, high-quality alloys during the single-step zone melting process.

The Mechanics of Thermal Stability

Exceeding Critical Melting Points

To create Bismuth Telluride, the processing environment must reliably exceed the melting points of the individual elements.

A Muffle furnace is configured to hold a steady temperature of 700 °C. This temperature is significantly higher than the melting points of both Bismuth and Tellurium, ensuring that no solid material remains and the reactants are fully available for synthesis.

Sustaining Deep Reactions

Achieving a high-quality alloy is not merely about reaching a specific temperature; it is about sustaining it.

The furnace facilitates a deep reaction by maintaining this high heat for an extended duration, typically around 12 hours. This prolonged exposure ensures that the atomic structures have sufficient time to interact and bond correctly.

Impact on Alloy Uniformity

Controlling the Thermal Field

The primary advantage of an industrial-grade Muffle furnace in this application is the stability of its thermal field.

Fluctuations in temperature can lead to inconsistencies in the material's crystal structure. By isolating the heating chamber from outside interference (the "muffle" design), the furnace creates a uniform heat zone that is essential for producing high-quality alloys.

Ensuring Homogeneity

For semiconductor materials like Bismuth Telluride, material consistency is paramount.

The stable thermal environment prevents the formation of localized defects or segregation of elements. This results in a final product with high uniformity, which is critical for the reliable performance of the material in electronic applications.

Understanding the Trade-offs

Process Duration vs. Throughput

While the Muffle furnace ensures quality, it imposes a significant time cost.

The requirement for a 12-hour heating cycle to ensure deep reactions inherently limits production speed. This is a batch process, meaning high-volume throughput requires multiple units or larger chamber capacities rather than faster cycle times.

Energy Consumption

Maintaing 700 °C for half a day requires significant energy input.

Although modern Muffle furnaces are designed with advanced insulation and recovery systems to minimize loss, the specific requirements of Bismuth Telluride processing make energy efficiency a critical operational consideration. The cost of electricity must be weighed against the value of the high-purity alloy produced.

Making the Right Choice for Your Goal

To optimize your material processing strategy, consider your specific production priorities:

- If your primary focus is Alloy Uniformity: Prioritize a furnace with verified thermal field stability to prevent structural defects, even if it extends cycle times.

- If your primary focus is Cost Management: Evaluate the insulation rating and energy recovery features of the furnace to mitigate the operational costs of the 12-hour heating cycle.

By leveraging the precise temperature control of a Muffle furnace, you ensure the structural integrity and performance reliability of your Bismuth Telluride materials.

Summary Table:

| Feature | Requirement for Bismuth Telluride | Muffle Furnace Benefit |

|---|---|---|

| Temperature | ~700 °C | Exceeds elemental melting points for full liquefaction |

| Stability | High Thermal Field Consistency | Prevents crystal defects and element segregation |

| Duration | 12-Hour Continuous Heating | Ensures deep chemical reaction and high homogeneity |

| Material Quality | High Alloy Uniformity | Provides isolated environment for structural integrity |

Elevate Your Material Synthesis with KINTEK

Precision thermal fields are the foundation of high-performance semiconductor alloys. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of Bismuth Telluride processing.

Whether you need customizable lab high-temp furnaces for unique research or scalable industrial solutions, our systems provide the unwavering stability required for 12-hour deep reactions and superior alloy uniformity. Contact KINTEK today to discover how our advanced furnace technology can optimize your material quality and laboratory efficiency.

Visual Guide

References

- N.G. Imam, Abd El‐Hady B. Kashyout. Comprehensive study of nanostructured Bi <sub>2</sub> Te <sub>3</sub> thermoelectric materials – insights from synchrotron radiation XRD, XAFS, and XRF techniques. DOI: 10.1039/d3ra06731a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are some common industrial applications of muffle furnaces? Unlock Precision Heat for Your Materials

- Why is a muffle furnace required for sodium-ion cathode heat treatment? Engineering P2/P3 Crystal Phase Structures

- How have modern muffle furnaces improved compared to older designs? Discover Precision, Purity & Efficiency

- What role does a muffle furnace play in refractory bricks? Enhance Performance and Durability Testing

- What is the primary function of a Muffle Furnace during the initial stages of lignin and humic substance extraction?

- What is the primary function of a high-temperature muffle furnace in ZnO nanopowder production? Key Roles in Calcination

- What industrial applications use muffle furnaces? Essential for Clean, High-Temp Processes

- How does a laboratory box furnace contribute to the temperature program control for synthesizing PrVSb3 single crystals?