In short, modern muffle furnaces have evolved from simple high-temperature ovens into precision instruments. The key improvements lie in superior temperature control and uniformity, enhanced sample purity through better isolation and electric heating, and sophisticated automation that ensures repeatable, reliable results.

The central advancement is the shift from a basic heating box to a highly controlled processing environment. This transformation allows modern furnaces to deliver the precision, purity, and high-temperature capabilities required for advanced materials research and quality control.

Precision Temperature Control and Uniformity

The most significant leap forward is in the ability to precisely manage heat. This is not just about reaching a target temperature, but about how that temperature is maintained throughout the entire chamber and over time.

From Manual to Automated Regulation

Older furnaces often relied on manual adjustments and simple thermostats, leading to temperature fluctuations. Modern furnaces use programmable digital controllers and microprocessor-controlled thermoregulators to execute complex heating and cooling cycles with exceptional accuracy.

This automation ensures that every process is identical, which is critical for validating research or maintaining consistent quality in production.

The Critical Role of Uniformity

Modern designs focus heavily on temperature uniformity, ensuring there are no significant hot or cold spots within the heating chamber. This means a sample, regardless of its position, experiences the exact same thermal conditions.

This is vital for applications like materials research and heat-treating, where even small temperature deviations across a sample can lead to inconsistent results and flawed data.

Higher Temperature Capabilities

Advances in heating element materials, such as specialized iron-chrome alloys, have pushed the operational limits of modern furnaces. Many can now reliably operate at temperatures exceeding 1000°C, with high-performance models reaching 1,800°C (3,272°F).

This capability unlocks advanced metallurgical applications and the development of new ceramics and composite materials that were impossible to process in older, lower-temperature furnaces.

Ensuring Sample Purity and Isolation

A core function of a muffle furnace is to isolate the heated material. Modern furnaces have perfected this function, guaranteeing that samples are not altered by external factors.

The "Muffle" Perfected

The term "muffle" refers to the insulated chamber that separates the sample from the heat source and outside atmosphere. Modern designs use superior insulation and chamber construction to prevent heat loss and isolate samples from any potential contaminants.

The Shift to Electric Heating

Many older furnaces were fuel-fired, producing combustion byproducts that could contaminate samples. The vast majority of modern lab-grade furnaces are electric.

They use inert heating elements that produce no combustion pollutants, ensuring that the only changes to a sample are a direct result of the applied heat. This is essential for sensitive analytical procedures like ashing.

Advanced Atmosphere Control

Beyond simple isolation, some high-performance furnaces offer features for controlling the atmosphere within the chamber. This can include low or high dewpoint features, allowing for processes that require specific humidity levels or inert gas environments.

Understanding the Trade-offs

While the advantages of modern furnaces are clear, it's important to consider the practical implications of this advanced technology.

Cost and Complexity

The precision components, advanced controllers, and superior materials in modern furnaces make them more expensive than their simpler predecessors. Their sophisticated features may also require a steeper learning curve for operators.

Maintenance and Repair

While generally reliable, the digital controls and specialized heating elements in a modern unit can be more complex and costly to service than the straightforward mechanical parts of an older furnace.

Enhanced Automation and Efficiency

Modern design philosophy emphasizes not just performance but also usability and operational efficiency, integrating furnaces into a complete workflow.

Turn-Key Automated Systems

High-end industrial models can be part of a turn-key automated system. Features like automated pusher systems, preheat sections, and binder removal sections allow for a continuous, multi-stage process with minimal human intervention.

Energy and Space Savings

Improved insulation materials and more efficient heating element designs mean modern furnaces consume less energy to reach and maintain temperature. They are often designed to have a smaller footprint, saving valuable lab or floor space.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on the precision, purity, and temperature your work demands.

- If your primary focus is analytical research or quality control: Prioritize a modern furnace with a microprocessor controller for its superior temperature uniformity and process repeatability.

- If your primary focus is high-temperature materials science: You will require a modern furnace capable of reaching temperatures up to 1,800°C with advanced material components.

- If your primary focus is routine processes like ashing or simple heat-treating: A modern electric furnace is still the best choice for its contaminant-free environment and energy efficiency.

Ultimately, investing in a modern muffle furnace is an investment in the accuracy and reliability of your results.

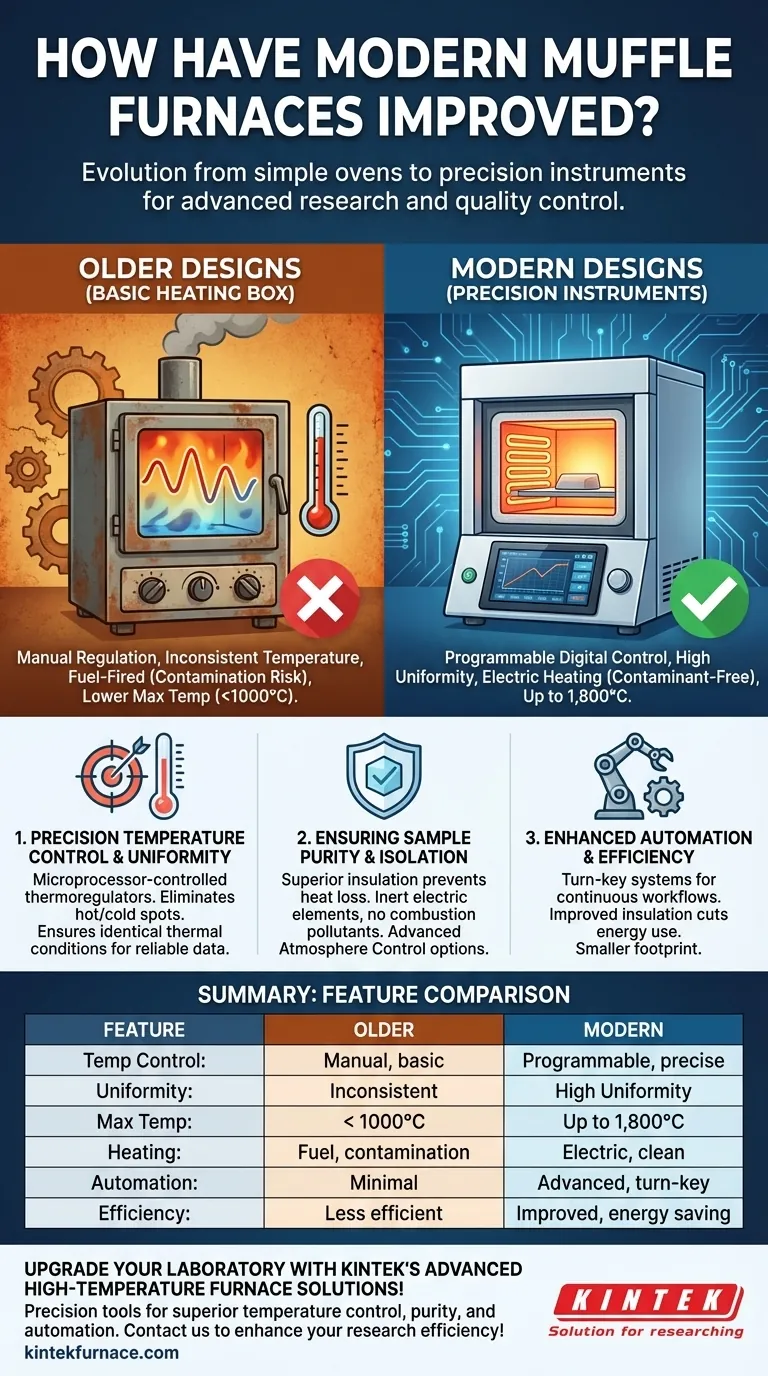

Summary Table:

| Feature | Older Designs | Modern Designs |

|---|---|---|

| Temperature Control | Manual, basic thermostats | Programmable digital controllers, precise regulation |

| Temperature Uniformity | Inconsistent, hot/cold spots | High uniformity across chamber |

| Max Temperature | Lower, often < 1000°C | Up to 1,800°C with advanced materials |

| Heating Method | Often fuel-fired, risk of contamination | Electric, contaminant-free |

| Automation | Minimal, manual operation | Advanced, with programmable cycles and turn-key systems |

| Energy Efficiency | Less efficient, more heat loss | Improved insulation, lower energy use |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior temperature control, purity, and automation. Contact us today to enhance your research and production efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination