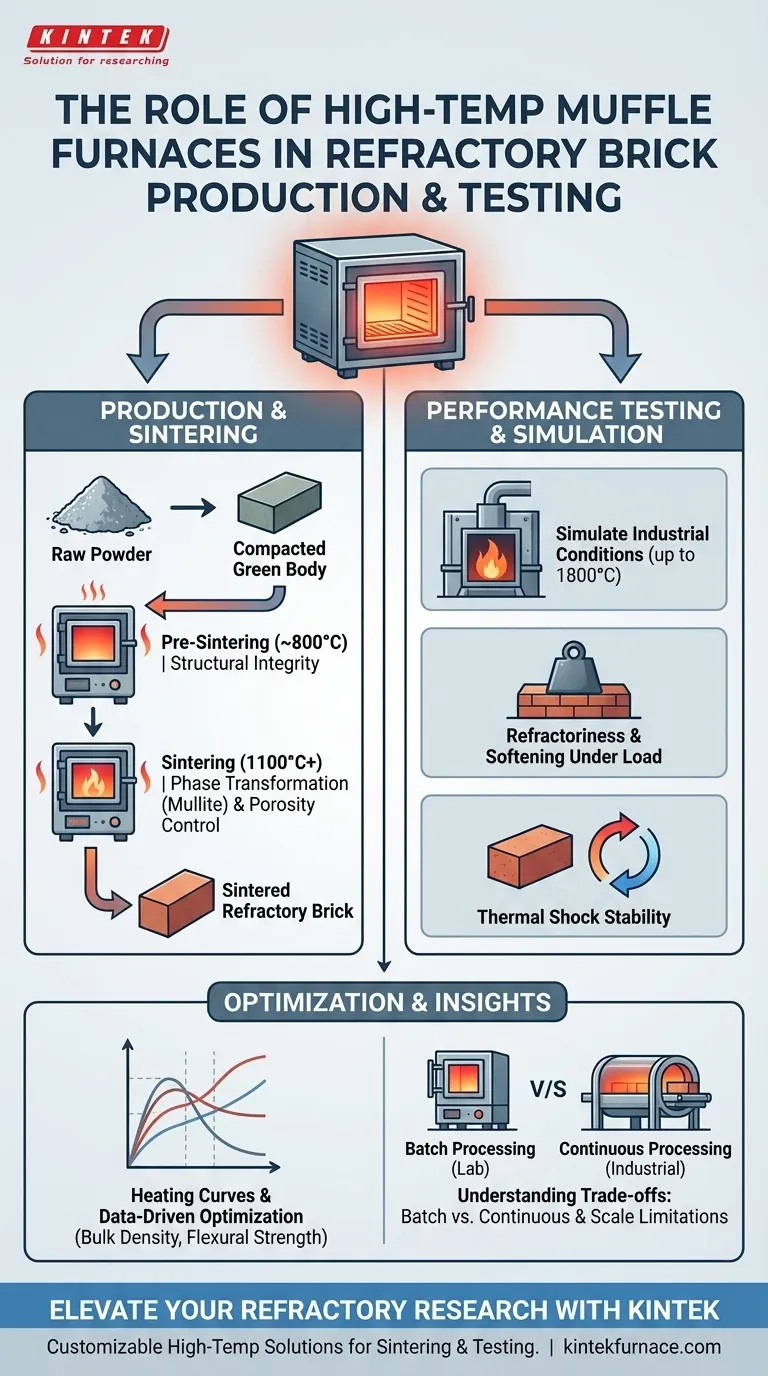

A laboratory high-temperature muffle furnace serves as the critical validation tool connecting raw material formulation to industrial viability. It plays a dual role: it acts as a production unit for sintering green bodies to induce necessary phase changes, and as a testing ground to rigorously simulate extreme operating environments—such as cement kilns—to validate physical limits like refractoriness and thermal shock resistance.

The core value of a high-temperature muffle furnace lies in its ability to replicate the thermal intensity of industrial kilns (up to 1800°C) within a controlled setting, allowing researchers to precisely correlate heating curves with material durability and structural integrity.

The Role in Production and Sintering

The production of high-quality refractory bricks requires precise thermal treatment to transform raw compacted powder into a durable ceramic material.

Pre-Sintering for Structural Integrity

Before full firing, the furnace is often used for a pre-sintering stage, typically heating cold-pressed green compacts to temperatures around 800°C. This step initiates the bonding of powder particles under atmospheric pressure. It improves the structural integrity of the compact, ensuring it is robust enough for subsequent densification processes like high-pressure hot re-pressing.

Driving Mineral Phase Transformations

During the primary sintering phase, the furnace provides a stable thermal field, often held between 1000°C and 1100°C or higher depending on the material. This sustained heat promotes critical mineralogical changes, such as transforming kaolinite into metakaolinite and eventually into mullite crystalline phases. This phase transformation is what gives refractory bricks their thermal resistance and mechanical strength.

Microstructure and Porosity Control

The furnace's precise temperature control directly dictates the evolution of the brick's internal microstructure. By manipulating the heat, engineers can control the growth of mullite crystals and adjust the material's porosity. These factors are the primary determinants of the final brick's density and insulating properties.

The Role in Performance Testing and Simulation

Once a prototype is created, the muffle furnace shifts roles from production to rigorous stress testing to ensure the brick can survive actual service conditions.

Simulating Industrial Kiln Conditions

A high-temperature muffle furnace capable of reaching 1800°C is essential for simulating the working conditions of heavy industrial equipment, such as cement kilns. This allows researchers to verify how the material will behave in the field before mass production begins.

Testing Refractoriness and Softening

The furnace is used to determine the softening temperature under load. This test identifies the exact temperature at which a brick begins to deform while supporting weight, a vital safety metric for structural refractories. It also validates the material's overall refractoriness—its ability to withstand heat without melting.

Thermal Shock Stability

The furnace enables thermal shock stability cycle experiments. By subjecting the bricks to rapid heating and cooling cycles, researchers can assess the material's resistance to cracking or spalling. This mimics the fluctuating temperatures found in operational industrial furnaces.

Optimizing Material Metrics

Beyond basic firing, the muffle furnace is a tool for data-driven optimization.

Establishing Heating Curves

Researchers use the furnace to set and execute precise heating curves. This allows for the systematic study of how different heating rates and dwell times affect the final product.

Correlating Temperature to Performance

By varying the sintering temperatures, engineers can map out the relationship between heat input and core performance indicators. Specifically, this process helps optimize the bulk density and flexural strength of the refractory bricks, ensuring they meet specific mechanical standards.

Understanding the Trade-offs

While the muffle furnace is indispensable, it is important to recognize the limitations inherent in laboratory-scale testing.

Batch vs. Continuous Processing

Muffle furnaces operate as batch processors, whereas most industrial brick production occurs in continuous tunnel kilns. While the muffle furnace accurately tests the material chemistry, it may not perfectly replicate the thermal gradients or flowing atmosphere of a continuous production line.

Scale Limitations

The "large storage capacity" of a lab furnace is relative; it allows for simultaneous testing of multiple samples, but it cannot produce full-scale production volumes. Data derived from these furnaces must be carefully scaled up, as mass effects in larger loads can alter heat distribution.

Making the Right Choice for Your Goal

To maximize the utility of a high-temperature muffle furnace, align your usage with your specific technical objectives.

- If your primary focus is Material Formulation: Focus on the dwell time accuracy in the 1000°C–1100°C range to ensure complete phase transformation and optimal mullite crystal growth.

- If your primary focus is Quality Assurance: Prioritize the maximum temperature capability (1800°C) and thermal cycling features to stress-test the refractoriness and shock stability of the finished product.

Ultimate success in refractory production relies on using the muffle furnace not just to "bake" samples, but to systematically stress and analyze the material's limits before it ever reaches the industrial kiln.

Summary Table:

| Stage | Role of Muffle Furnace | Key Outcomes |

|---|---|---|

| Sintering | Controlled heating up to 1100°C+ | Promotes mullite phase transformation and structural integrity. |

| Phase Control | Sustained thermal field | Optimizes microstructure, porosity, and mineralogical development. |

| Performance Testing | High-temp simulation (up to 1800°C) | Validates refractoriness, softening under load, and thermal shock stability. |

| Optimization | Heating curve precision | Maximizes bulk density and flexural strength through data-driven testing. |

Elevate Your Refractory Research with KINTEK

Precision thermal processing is the foundation of high-performance refractory materials. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces—all fully customizable to meet your unique sintering and testing needs.

Whether you are refining material formulations or conducting rigorous thermal shock simulations, our equipment ensures the accuracy and reliability your lab demands. Contact us today to find the perfect high-temperature solution for your application.

Visual Guide

References

- Samuel Audu Seth, Jacob Jatau. Production and Characterisation of Refractory Bricks for Cement Kiln Burning Zone Application. DOI: 10.11648/j.ie.20250901.13

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the different types of muffle furnaces? Choose the Right Furnace for Your Lab Needs

- What role do muffle furnaces play in the pharmaceutical industry? Essential for Quality Control and R&D

- Why is a desktop drying oven used for CeZrPAl supports? Essential Tips for Structural Integrity

- Why is a high-temperature muffle furnace required for the roasting of activated fly ash? Unlock Efficient Phase Changes

- What is the role of a high-temperature muffle furnace in treating Mn3O4 nanowires? Optimize Phase Stability

- How does a muffle furnace system integrated with a nitrogen gas supply facilitate the preparation of biochar?

- What makes muffle furnaces particularly useful for sensitive materials? Ensure Precision, Purity & Protection

- What are the primary uses of a muffle furnace in material testing? Essential for Analysis, Modification, and Performance Evaluation