A muffle furnace integrated with a nitrogen gas supply functions as a precise reactor for converting raw biomass into biochar through controlled pyrolysis. This system works by continuously purging the heating chamber with nitrogen to exclude oxygen, while simultaneously applying high temperatures (typically 500 °C to 800 °C) to thermally decompose the organic material without burning it.

Core Insight: The primary function of this integrated system is to decouple heating from combustion. By replacing the atmosphere with inert nitrogen, you force the biomass to undergo slow pyrolysis rather than oxidation, preserving the carbon skeleton and creating the distinct porous structure that defines high-quality biochar.

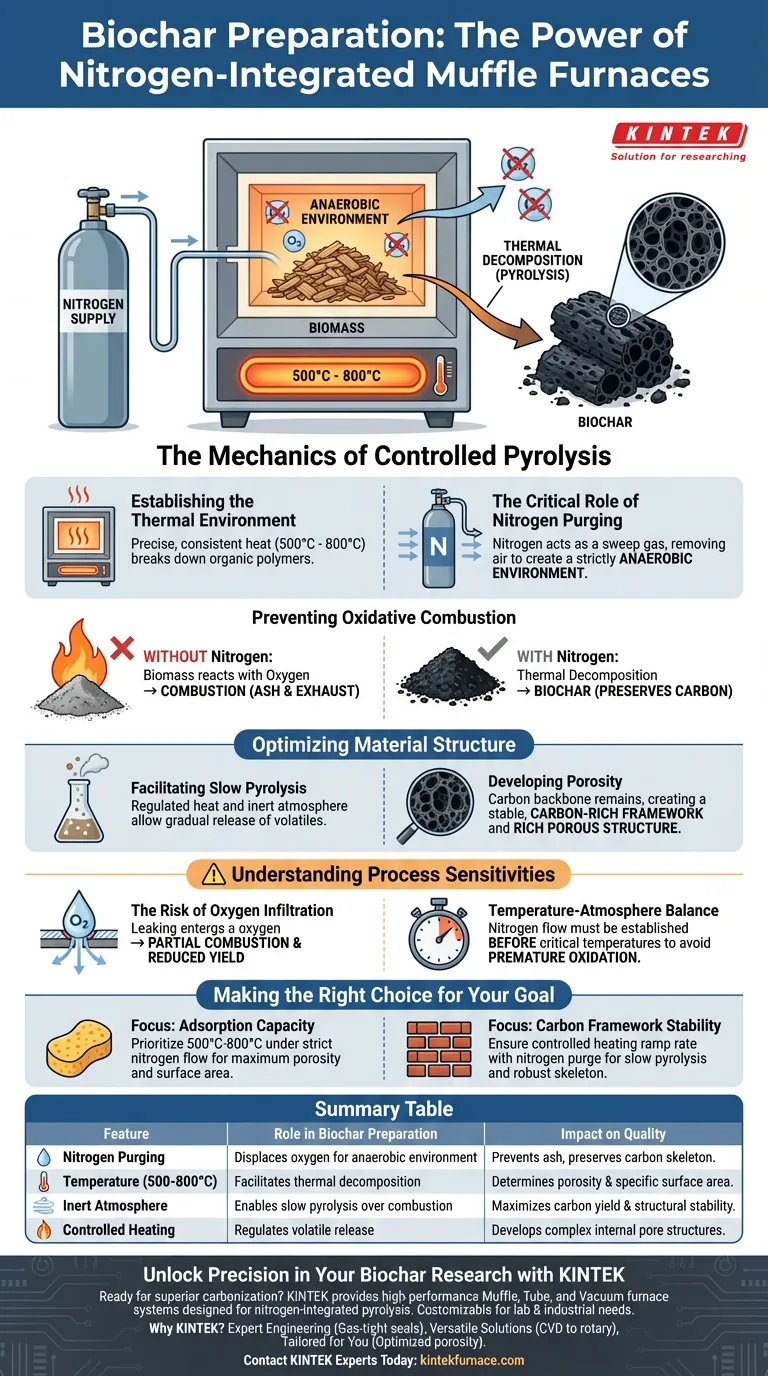

The Mechanics of Controlled Pyrolysis

Establishing the Thermal Environment

The muffle furnace provides the precise, consistent heat required to break down complex organic polymers. To initiate the carbonization process effectively, the furnace must maintain temperatures generally ranging from 500 °C to 800 °C.

The Critical Role of Nitrogen Purging

The introduction of a nitrogen gas supply is the defining factor in this setup. Nitrogen acts as a sweep gas, continuously flushing the reactor to remove air and displace oxygen.

This creates and maintains a strictly anaerobic environment throughout the heating cycle.

Preventing Oxidative Combustion

Without the nitrogen supply, high temperatures would cause the biomass to react with oxygen, resulting in direct combustion. This would turn the valuable feedstock into ash and exhaust gases rather than biochar.

Nitrogen prevents this chemical reaction, ensuring the material undergoes thermal decomposition rather than burning.

Optimizing Material Structure

Facilitating Slow Pyrolysis

The combination of regulated heat and an inert atmosphere facilitates "slow pyrolysis." This method allows for the gradual release of volatiles from the biomass.

Developing Porosity

Because the carbon backbone is not consumed by fire, the process leaves behind a stable, carbon-rich framework. This results in biochar characterized by a rich porous structure, which is essential for applications like adsorption or soil amendment.

Understanding Process Sensitivities

The Risk of Oxygen Infiltration

The integrity of the biochar depends entirely on the reliability of the nitrogen seal. Even minor oxygen leaks during the high-temperature phase can lead to partial combustion, significantly reducing yield and damaging surface properties.

Temperature-Atmosphere Balance

Ideally, the nitrogen flow must be established before the furnace reaches critical temperatures. Heating the biomass before the chamber is fully purged can trigger premature oxidation, degrading the quality of the final carbon lattice.

Making the Right Choice for Your Goal

To maximize the utility of your muffle furnace and nitrogen system, consider your specific end-goals for the biochar:

- If your primary focus is Adsorption Capacity: Prioritize the 500 °C to 800 °C range under strict nitrogen flow to maximize the development of the porous structure and specific surface area.

- If your primary focus is Carbon Framework Stability: Ensure the heating ramp rate is controlled alongside the nitrogen purge to facilitate slow pyrolysis, which builds a robust carbon skeleton.

Success in biochar preparation relies not just on heat, but on the absolute exclusion of oxygen to unlock the material's porous potential.

Summary Table:

| Feature | Role in Biochar Preparation | Impact on Quality |

|---|---|---|

| Nitrogen Purging | Displaces oxygen to create anaerobic environment | Prevents ash formation; preserves carbon skeleton |

| Temperature (500-800°C) | Facilitates thermal decomposition of biomass | Determines porosity and specific surface area |

| Inert Atmosphere | Enables slow pyrolysis over combustion | Maximizes carbon yield and structural stability |

| Controlled Heating | Regulates the release of volatiles | Develops complex internal pore structures |

Unlock Precision in Your Biochar Research with KINTEK

Ready to achieve superior carbonization results? KINTEK provides high-performance Muffle, Tube, and Vacuum furnace systems specifically designed for nitrogen-integrated pyrolysis. Backed by expert R&D and precision manufacturing, our systems are fully customizable to meet the rigorous demands of laboratory and industrial high-temperature applications.

Why choose KINTEK?

- Expert Engineering: Specialized gas-tight seals for perfect anaerobic environments.

- Versatile Solutions: From CVD systems to rotary furnaces, we cover all lab thermal needs.

- Tailored for You: Customizable heating rates and gas flow controls to optimize your material porosity.

Contact KINTEK Experts Today to find the perfect thermal solution for your unique research needs!

Visual Guide

References

- Vishal Shah, Mohd Asif Shah. Effectiveness of <i>Canna indica</i> leaves and stalk biochar in the treatment of textile effluent. DOI: 10.1063/5.0191708

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the purpose of using a muffle furnace to fire Al2O3 ceramic shells at 1050°C? Enhance Strength and Purity

- What is the alternative to a muffle furnace? Choose the Right High-Temp Furnace for Your Process

- What temperature range can a box furnace operate in? Find the Perfect Fit for Your Lab's Needs

- Why is the temperature control precision of a box-type muffle furnace critical when converting precursors to ZnCo2O4?

- What precautions should be taken when placing items into the muffle furnace? Ensure Safety and Accuracy in High-Temp Operations

- What is a muffle furnace and how does it operate? Master Precise, Clean Heating for Your Lab

- What conditions do high-temperature muffle furnaces provide for Zirconia calcination? Optimize Your Thermal Synthesis

- How is a muffle furnace utilized during the high-temperature annealing of forged TiAl-SiC composites?