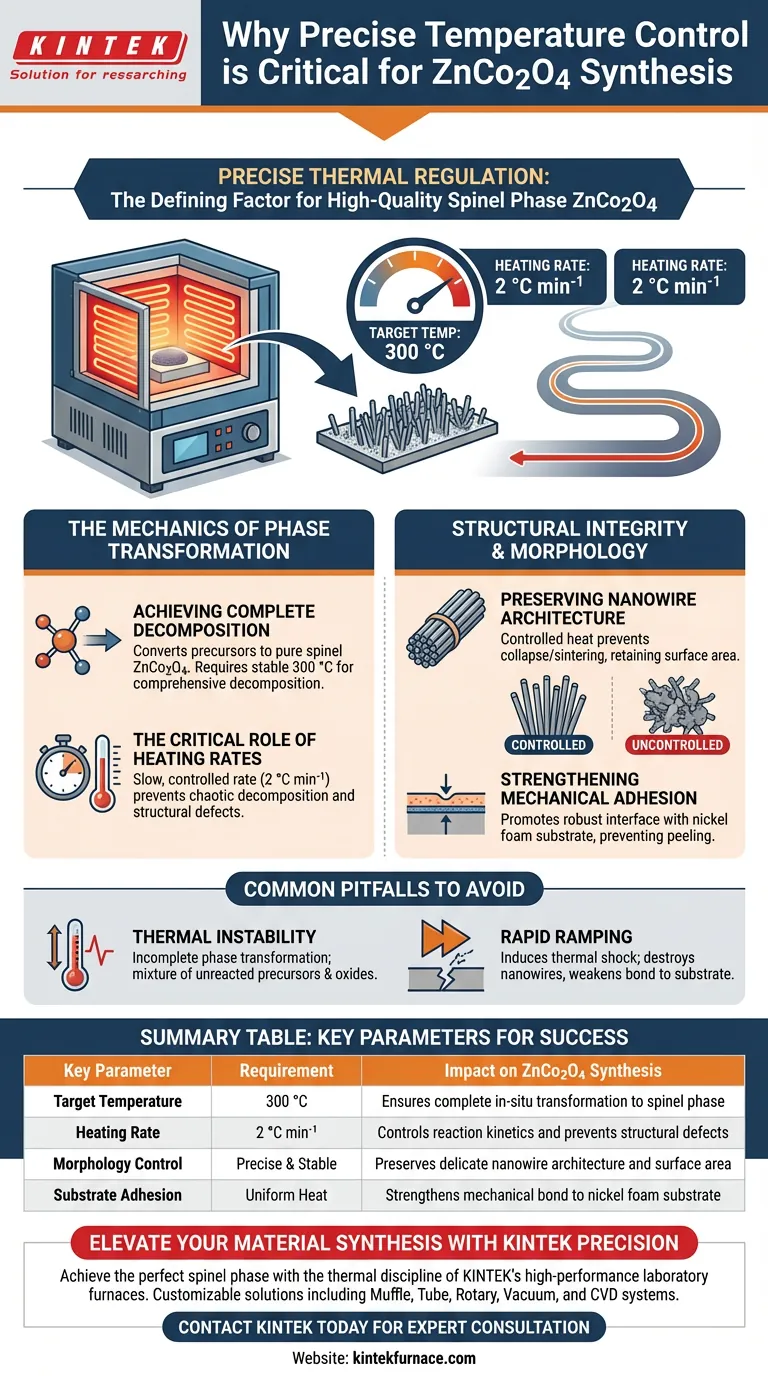

Precise thermal regulation is the defining factor in the successful synthesis of high-quality ZnCo2O4. A box-type muffle furnace is critical because it provides the exact heating rate (specifically 2 °C min⁻¹) and a stable 300 °C environment needed to drive thermal decomposition, ensuring the material undergoes a complete in-situ transformation into the spinel structure without destroying its delicate morphology.

Core Insight: The transition from precursor to active ZnCo2O4 is not just about reaching a temperature; it is about the path taken to get there. Precise control allows for full phase transformation while simultaneously strengthening the bond to the substrate and preserving the nanowire architecture.

The Mechanics of Phase Transformation

Achieving Complete Decomposition

The primary objective of the heating process is to convert precursors into a pure spinel-structured ZnCo2O4.

This conversion requires a stable high-temperature environment, typically centered around 300 °C.

A box-type muffle furnace maintains this specific temperature window with high accuracy, ensuring that the thermal decomposition of the precursor is comprehensive and consistent throughout the sample.

The Critical Role of Heating Rates

The speed at which the material is heated is just as important as the final temperature.

The furnace must deliver a slow, controlled heating rate, such as 2 °C min⁻¹.

This gradual ramp controls the reaction kinetics, preventing rapid, chaotic decomposition that could lead to impurities or structural defects in the final crystal lattice.

Structural Integrity and Morphology

Preserving Nanowire Architecture

The efficacy of ZnCo2O4 often depends on its specific morphology, such as a nanowire structure.

Rapid heating or thermal fluctuations can cause these delicate nanostructures to collapse or sinter together.

By strictly controlling the thermal environment, the furnace ensures that the "in-situ" transformation occurs gently enough to retain the specific nanowire shape, which is vital for the material's surface area.

Strengthening Mechanical Adhesion

The synthesis process involves growing the active substance directly onto a substrate, commonly nickel foam.

Precise thermal treatment strengthens the mechanical adhesion between the ZnCo2O4 and this substrate.

A stable furnace environment promotes a robust interface, preventing the active material from peeling off during subsequent use.

Common Pitfalls to Avoid

The Consequence of Thermal Instability

If the furnace cannot hold the 300 °C target effectively, the phase transformation may remain incomplete.

This results in a material that is a mixture of unreacted precursors and oxides, rather than the pure spinel phase required for optimal performance.

The Risk of Rapid Ramping

Ignoring the 2 °C min⁻¹ limit to speed up the process is a frequent error.

Accelerated heating induces thermal shock, which destroys the nanowire morphology and weakens the structural bond to the nickel foam, rendering the material mechanically unstable.

Making the Right Choice for Your Synthesis

To maximize the quality of your ZnCo2O4 production, align your equipment settings with your specific material goals:

- If your primary focus is Phase Purity: Prioritize a furnace with exceptional stability at 300 °C to guarantee the thorough decomposition of precursors into the spinel structure.

- If your primary focus is Morphological Integrity: Ensure your equipment allows for programmable, low-speed ramping (2 °C min⁻¹) to protect the nanowire structure and ensure strong substrate adhesion.

Success in this synthesis relies not on heat alone, but on the disciplined application of that heat over time.

Summary Table:

| Key Parameter | Requirement | Impact on ZnCo2O4 Synthesis |

|---|---|---|

| Target Temperature | 300 °C | Ensures complete in-situ transformation to spinel phase |

| Heating Rate | 2 °C min⁻¹ | Controls reaction kinetics and prevents structural defects |

| Morphology Control | Precise & Stable | Preserves delicate nanowire architecture and surface area |

| Substrate Adhesion | Uniform Heat | Strengthens mechanical bond to nickel foam substrate |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect spinel phase in ZnCo2O4 requires more than just heat; it requires the absolute thermal discipline found in KINTEK’s high-performance laboratory furnaces.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to deliver the precise 2 °C min⁻¹ ramping and temperature stability your research demands. Whether you are preserving nanowire morphology or ensuring substrate adhesion, our customizable solutions are built for your unique needs.

Ready to optimize your thermal processing?

Contact KINTEK Today for a Expert Consultation

Visual Guide

References

- Yanlei Bi, Lu‐Chang Qin. Rational synthesis of 3D coral-like ZnCo<sub>2</sub>O<sub>4</sub> nanoclusters with abundant oxygen vacancies for high-performance supercapacitors. DOI: 10.1039/d4ra00927d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of a high-temperature box furnace in the synthesis of silico-sulfate-phosphate glass fertilizers?

- Why use a high-temp box resistance furnace for Ca2.5Ag0.3Sm0.2Co4O9 sintering? Ensure Phase Purity and Alignment

- What role does a box furnace play in alloy melting? Achieve Precision and Purity in Material Science

- Why is a high-temperature box resistance furnace essential for failure analysis? Master TGO Growth and Isothermal Testing

- What temperature range is typical for furnace gas in a box type resistance furnace? Learn How to Choose the Right Furnace for Your Needs

- What temperature range can muffle furnaces reach? Find Your Ideal Lab Furnace Temperature

- How is a laboratory Muffle furnace utilized in the heat treatment of DP steel? Optimize Martensite & Strength

- What is the function of a high-temperature muffle furnace? Master Eggshell Adsorbent Activation