When placing items into a muffle furnace, your primary precautions are to position the sample centrally using long crucible tongs, ensure you do not touch the delicate thermocouple sensor, and cut power before loading or unloading. These steps are fundamental to protecting both the equipment and yourself from the extreme temperatures involved.

Operating a muffle furnace is a discipline of managing extreme heat. Success and safety are not just about the heating cycle itself, but about the precise, careful actions taken during loading and—most critically—during the cooling and unloading phase to prevent equipment damage and personal injury.

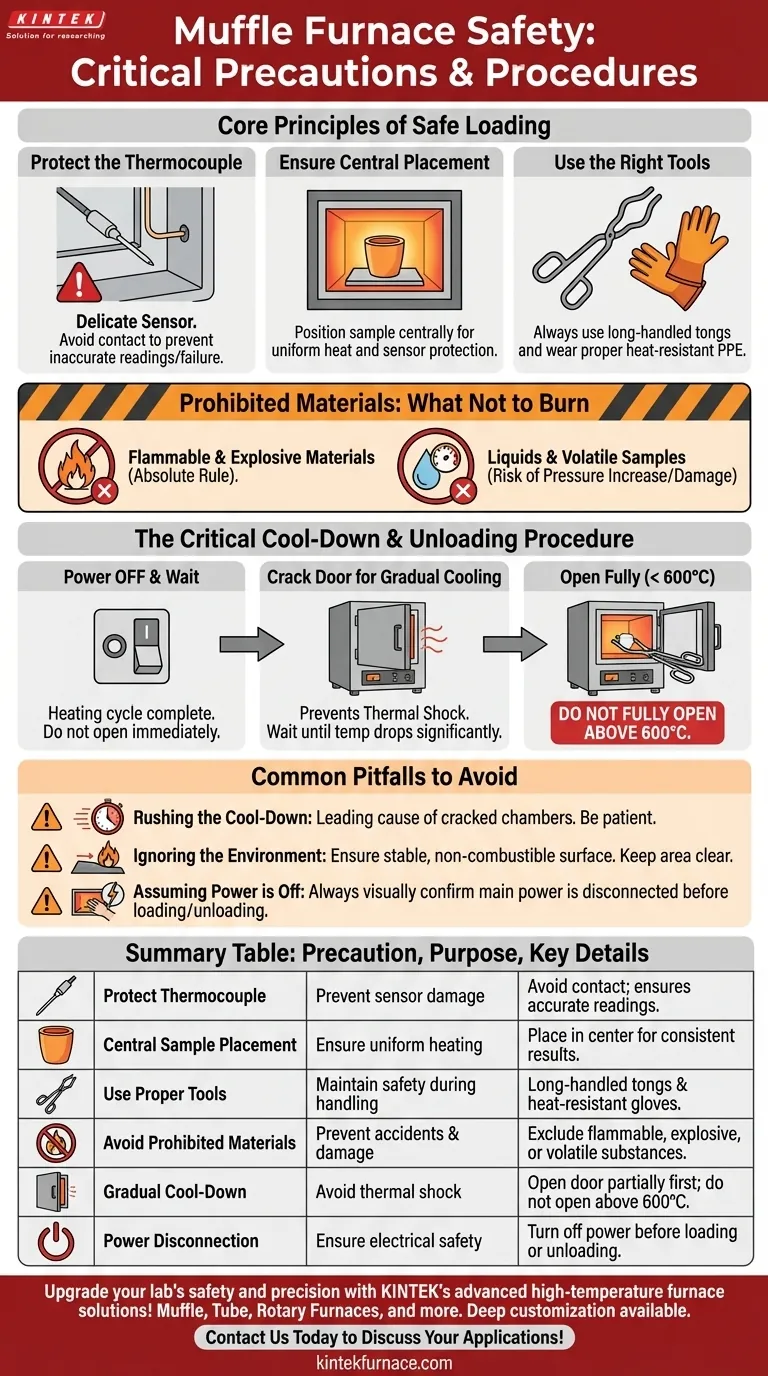

The Core Principles of Safe Loading

Understanding the "why" behind furnace procedures transforms them from a simple checklist into a framework for safe and effective operation. Each step is designed to mitigate a specific risk associated with high-temperature work.

Protect the Thermocouple

The thermocouple is the furnace's nerve center, a sensor that extends into the heating chamber to measure and regulate temperature. It is extremely fragile, especially when hot.

Contacting the thermocouple with crucible tongs or the sample itself can easily cause it to break. A broken thermocouple leads to inaccurate temperature readings or complete failure of the furnace's control system.

Ensure Stable and Even Heating

Place your crucibles or other sample containers as close to the center of the furnace as possible.

This central placement ensures the most uniform heat exposure, leading to more accurate and repeatable results. It also keeps the sample away from direct contact with the heating elements and the sensitive thermocouple.

Use the Right Tools and PPE

Never handle items for the furnace with your hands. Always use long-handled crucible tongs to maintain a safe distance and handle items with a gentle, deliberate motion.

Heat-resistant gloves are mandatory. While they provide essential protection against burns, remember they are not designed for prolonged contact with hot surfaces. Their purpose is to protect you during the brief moments of loading and unloading.

Prohibited Materials: What Not to Burn

A muffle furnace is designed for stable, high-temperature ashing, heat-treating, and burning of specific materials. Introducing the wrong substance can lead to catastrophic failure.

Flammable and Explosive Materials

This is an absolute rule. Never place any flammable, volatile, or potentially explosive materials inside the furnace. Likewise, the area around the furnace must be kept completely clear of these substances.

Liquids and Volatile Samples

Do not pour liquids or place samples with high oil or moisture content directly into a hot furnace. The rapid vaporization can create a sudden pressure increase inside the sealed chamber, potentially damaging the door, the insulation, or causing a dangerous release of hot gas.

The Critical Cool-Down and Unloading Procedure

How you remove a sample is just as important as how you put it in. The greatest risk of damage to the furnace chamber comes from rapid, uncontrolled temperature changes.

The Danger of Thermal Shock

The refractory materials that line the furnace chamber are brittle. Opening the door fully while the furnace is at a very high temperature exposes the interior to a rush of cool air, creating thermal shock.

This rapid contraction can cause the furnace chamber to crack, leading to expensive and time-consuming repairs.

The Two-Stage Cooling Method

To prevent thermal shock, always follow a gradual cooling process. After the heating cycle is complete and the power is off, do not open the door immediately.

First, open the door just a small crack. This allows heat to dissipate and the internal temperature to drop in a more controlled manner. Once the temperature has fallen significantly, you can then open the door fully to remove your sample.

The 600°C Guideline

As a firm rule, do not fully open the furnace door if the internal temperature is above 600°C. Wait for the furnace to cool below this threshold before retrieving your samples with tongs.

Common Pitfalls to Avoid

Even experienced operators can make mistakes. Being aware of common pitfalls is key to maintaining a safe and efficient workflow.

Pitfall: Rushing the Cool-Down

The most common mistake is impatience. Trying to retrieve a sample too quickly by opening the door while the furnace is still extremely hot is the leading cause of cracked furnace chambers. Always prioritize equipment longevity over speed.

Pitfall: Ignoring the Environment

The furnace itself radiates a significant amount of heat. Ensure the unit is on a stable, non-combustible surface like a cement platform and that the surrounding area is clear. A crowded workspace is a hazard.

Pitfall: Assuming Power is Off

Before reaching into the furnace for any reason, visually confirm that the main power supply has been turned off. This simple check prevents severe electrical shock and burn risks.

Applying This to Your Work

Your specific goal will determine which precautions are most critical in the moment, but all are part of a single, disciplined process.

- If your primary focus is equipment preservation: Strictly adhere to the two-stage, gradual cool-down procedure and never open the door above 600°C.

- If your primary focus is personal safety: Always wear appropriate PPE, use tongs for all sample handling, and double-check that power is disconnected before unloading.

- If your primary focus is accurate results: Ensure your samples are placed centrally to receive even heating and take extreme care to avoid damaging the thermocouple.

Mastering the use of a muffle furnace comes from respecting the immense energy it contains and internalizing the procedures that control it safely.

Summary Table:

| Precaution | Purpose | Key Details |

|---|---|---|

| Protect Thermocouple | Prevent damage to temperature sensor | Avoid contact with tongs or samples; ensures accurate readings |

| Central Sample Placement | Ensure uniform heating | Place crucibles in center for consistent results |

| Use Proper Tools | Maintain safety during handling | Employ long-handled crucible tongs and heat-resistant gloves |

| Avoid Prohibited Materials | Prevent accidents and damage | Exclude flammable, explosive, or volatile substances |

| Gradual Cool-Down | Avoid thermal shock | Open door partially first; do not open above 600°C |

| Power Disconnection | Ensure electrical safety | Turn off power before loading or unloading |

Upgrade your lab's safety and precision with KINTEK's advanced high-temperature furnace solutions!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, enhancing efficiency and results.

Don't compromise on safety or performance—contact us today to discuss how our tailored furnace solutions can benefit your specific applications!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?