In the pharmaceutical industry, a muffle furnace is a fundamental piece of laboratory equipment used for high-temperature thermal processing and analysis. Its primary roles include preparing samples for quality control testing, conducting stability studies, and determining the non-combustible or inorganic content of a drug substance. It provides a precisely controlled, high-temperature environment that is free from contaminants, which is essential for ensuring the accuracy and reproducibility of analytical results.

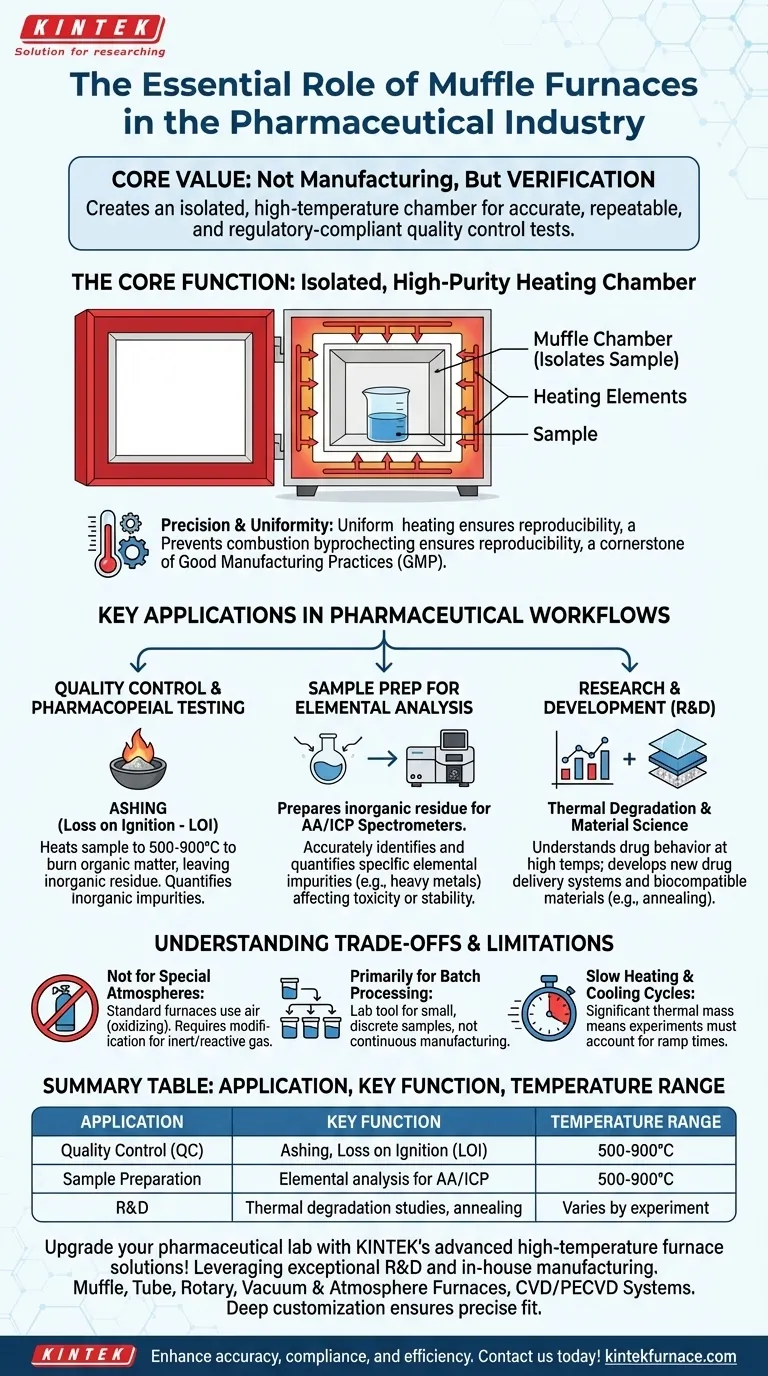

The core value of a muffle furnace in pharmaceuticals is not in manufacturing, but in verification. It creates an isolated, high-temperature chamber that removes organic material and prepares samples, ensuring that quality control tests are accurate, repeatable, and compliant with regulatory standards.

The Core Function: An Isolated, High-Purity Heating Chamber

A muffle furnace is more than just a high-temperature oven. Its design is central to its role in the highly regulated pharmaceutical world.

What Makes It a "Muffle" Furnace?

The defining feature is the "muffle," an inner chamber that contains the sample and isolates it from the heating elements.

This design prevents combustion byproducts, like gases or soot from the heating elements, from contaminating the pharmaceutical sample. This is critical for purity-dependent tests.

The Importance of Precision and Uniformity

Pharmaceutical analysis demands extremely reproducible conditions. Muffle furnaces provide uniform heating throughout the chamber, ensuring the entire sample experiences the same temperature.

This uniformity eliminates variables and ensures that a test conducted today will yield the same result as one conducted months from now, a cornerstone of Good Manufacturing Practices (GMP).

Key Applications in Pharmaceutical Workflows

The muffle furnace is a versatile tool that appears in several distinct stages of the pharmaceutical lifecycle, from early research to final quality control.

Quality Control and Pharmacopeial Testing

This is the furnace's most common application. It is essential for a standard test known as ashing.

Ashing involves heating a sample to a high temperature (e.g., 500-900°C) to burn off all organic matter, leaving only the inorganic, non-combustible residue.

This procedure, often called "Loss on Ignition" (LOI) or "residue on ignition," is a required test in many pharmacopeias to quantify inorganic impurities in a drug substance or final product.

Sample Preparation for Elemental Analysis

After ashing, the remaining inorganic residue is often dissolved and analyzed by other instruments, such as Atomic Absorption (AA) or Inductively Coupled Plasma (ICP) spectrometers.

This secondary analysis accurately identifies and quantifies specific elemental impurities (e.g., heavy metals) that could be toxic or affect the drug's stability. The muffle furnace is the critical first step in this analytical workflow.

Research and Development (R&D)

In R&D, furnaces are used for thermal degradation studies to understand how a drug substance or formulation behaves at high temperatures. This data informs storage conditions and predicts shelf life.

They are also used in materials science to develop new drug delivery systems or biocompatible materials, using processes like annealing to alter a material's physical properties for use in medical devices.

Understanding the Trade-offs and Limitations

While essential, a muffle furnace is a specific tool with its own operational boundaries. Understanding these limitations is key to using it correctly.

Not for Processes Requiring Special Atmospheres

A standard muffle furnace heats samples in the presence of air (an oxidizing atmosphere). It is not suitable for processes that require an inert (e.g., nitrogen, argon) or reactive atmosphere without significant modification.

Primarily for Batch Processing

Muffle furnaces are designed for processing small, discrete batches of samples. They are a laboratory tool, not a piece of equipment for large-scale, continuous manufacturing.

Slow Heating and Cooling Cycles

Due to their significant thermal mass and insulation, muffle furnaces do not heat up or cool down instantly. Experiments must account for these ramp times, which can be a limitation for high-throughput screening.

Making the Right Choice for Your Goal

Selecting the right features depends entirely on the intended application.

- If your primary focus is routine Quality Control (QC): Prioritize a furnace with exceptional temperature uniformity and certified calibration to ensure compliance with pharmacopeial standards.

- If your primary focus is Research and Development (R&D): Look for a furnace with fully programmable controls for multi-step temperature profiles and a wide operating range for diverse experiments.

- If your primary focus is preparing samples for trace metal analysis: Ensure the furnace's inner chamber is made from a high-purity, non-contaminating material to maintain sample integrity.

Ultimately, the muffle furnace serves as a gatekeeper of quality, providing the definitive thermal analysis required to validate the safety and consistency of pharmaceutical products.

Summary Table:

| Application | Key Function | Temperature Range |

|---|---|---|

| Quality Control (QC) | Ashing, Loss on Ignition (LOI) | 500-900°C |

| Sample Preparation | Elemental analysis for AA/ICP | 500-900°C |

| R&D | Thermal degradation studies, annealing | Varies by experiment |

Upgrade your pharmaceutical lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique quality control and research needs. Contact us today to enhance accuracy, compliance, and efficiency in your thermal processing workflows!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis