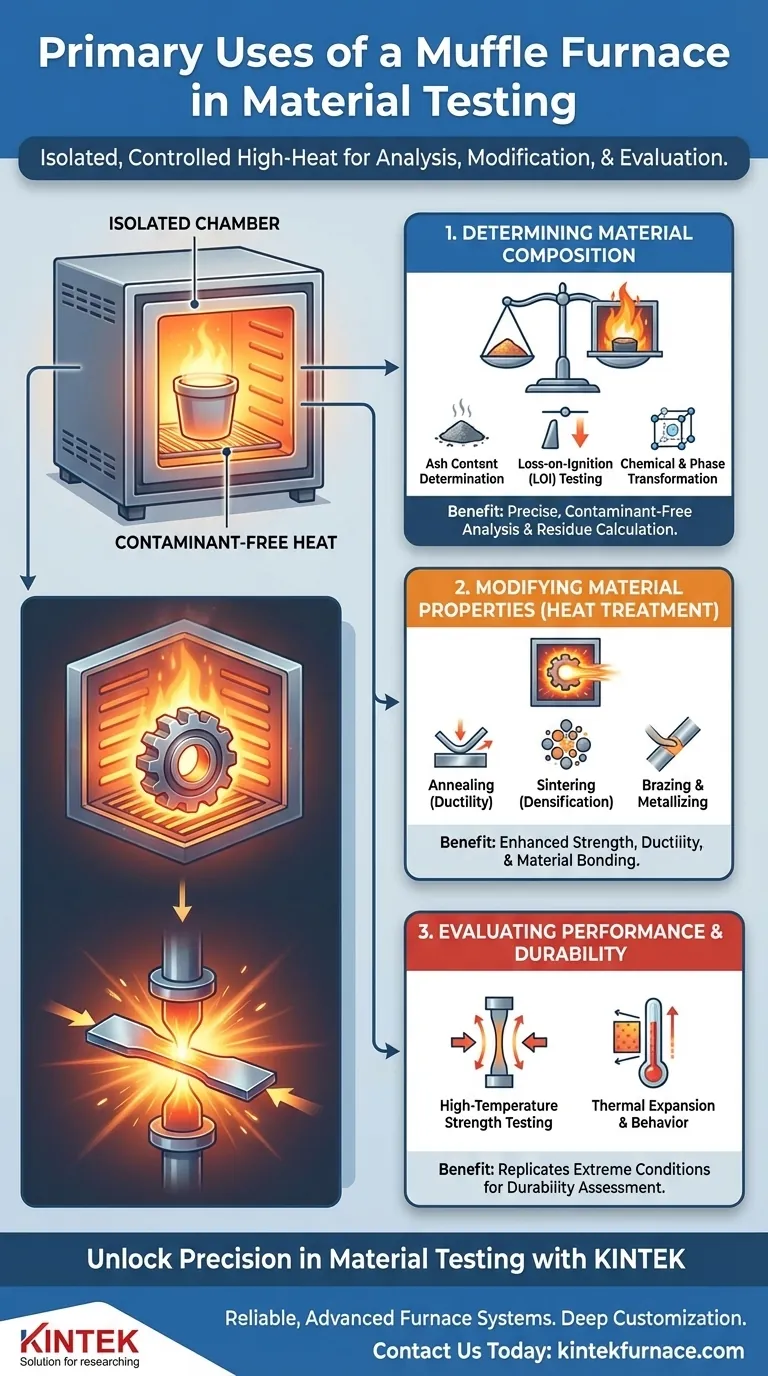

In material testing, a muffle furnace is primarily used for three key functions: analyzing a material's composition, modifying its physical properties through heat treatment, and evaluating its performance and durability under extreme thermal stress. These processes are foundational for quality control, research, and development across industries from ceramics and metallurgy to pharmaceuticals.

The core value of a muffle furnace is its ability to provide a highly controlled, high-temperature environment that is isolated from the contaminants of fuel combustion. This ensures that any changes to the material are a direct result of heat alone, enabling precise and repeatable analysis and treatment.

Determining Material Composition

One of the most fundamental uses of a muffle furnace is to break down a sample to understand what it's made of. The isolated, high-heat environment is ideal for separating volatile and non-volatile components.

Ash Content Analysis

The most common analytical application is ash content determination. A sample, such as coal, food, or a polymer, is placed in the furnace and heated until all organic and volatile substances burn away.

The remaining non-combustible inorganic residue is the ash. By weighing the sample before and after this process, you can precisely calculate the ash percentage, a critical quality metric in many fields.

Loss-on-Ignition (LOI) Testing

Closely related to ash analysis, loss-on-ignition testing measures the weight change in a material after it's been heated to a specific high temperature.

This test is often used for inorganic samples like cement or soil to determine the content of water or carbon dioxide, which is driven off during heating.

Chemical and Phase Transformation Studies

Researchers use muffle furnaces to study how materials change chemically at high temperatures. This includes observing phase transformations, where a material’s crystalline structure shifts, altering its properties.

Modifying Material Properties

A muffle furnace is not just an analytical tool; it is a critical instrument for intentionally altering the physical characteristics of a material to meet specific performance requirements. This is broadly known as heat treatment.

Annealing for Increased Ductility

Annealing involves heating a metal or glass and then cooling it slowly. This process relieves internal stresses and refines the material's microstructure.

The result is a material that is softer, less brittle, and more ductile, making it easier to work with and more resistant to fracture.

Sintering for Densification

In ceramics and powder metallurgy, sintering uses heat to fuse particles together into a solid, dense object without melting them completely.

The furnace provides the precise, sustained temperature needed to bond the particles, transforming a loose powder into a strong, engineered component.

Brazing and Metallizing

Brazing is a process for joining two pieces of metal by melting a filler metal into the joint. A muffle furnace provides the uniform, controlled heat necessary for a strong bond.

Similarly, metallizing involves applying a metallic coating onto a non-metallic surface, a process that often requires high-temperature firing in a furnace to create a durable layer.

Evaluating Performance and Durability

Beyond changing a material, a furnace is essential for testing how a finished material or component will behave in its intended service environment.

High-Temperature Strength Testing

Materials intended for high-heat applications, like engine components or furnace linings, must retain their strength.

Samples are heated in a muffle furnace to their expected operating temperature and then subjected to tensile strength tests to measure how their mechanical properties degrade under heat.

Thermal Expansion and Behavior

A muffle furnace is used to heat a material while its dimensions are carefully measured. This determines its coefficient of thermal expansion—a critical factor in designing parts where precise tolerances must be maintained across a range of temperatures.

Understanding the Trade-offs

While incredibly versatile, a muffle furnace is not a universal solution. Understanding its inherent design informs its proper application.

The Role of the "Muffle"

The term "muffle" refers to the furnace's inner chamber, which isolates the sample from the heating elements and any contaminants from fuel combustion.

This guarantees that heat is the primary variable. However, a standard furnace does not control the atmosphere; the sample is simply heated in air.

Temperature Uniformity

Achieving perfect temperature uniformity throughout the entire chamber can be a challenge. High-quality furnaces are designed to minimize hot and cold spots, but this is a key performance specification to consider for sensitive processes.

Atmospheric Control Limitations

For processes that require an inert (e.g., argon) or reducing (e.g., hydrogen) atmosphere to prevent oxidation, a standard muffle furnace is insufficient. These applications require specialized furnaces with sealed chambers and gas-handling capabilities.

Making the Right Choice for Your Goal

To apply the furnace effectively, align the process with your primary objective.

- If your primary focus is compositional analysis: You need a process with controlled burnout temperatures and access to a highly precise analytical balance for pre- and post-weighing.

- If your primary focus is property modification: Success depends on precise control over temperature ramp rates, hold times (soaks), and cooling profiles, as these dictate the final microstructure.

- If your primary focus is performance testing: The key is to accurately replicate the material's expected service conditions inside the furnace before conducting subsequent mechanical tests.

Ultimately, the muffle furnace is a foundational tool that empowers engineers and scientists to analyze, engineer, and validate materials by precisely controlling their most critical variable: heat.

Summary Table:

| Primary Use | Key Applications | Benefits |

|---|---|---|

| Composition Analysis | Ash content determination, Loss-on-ignition testing, Phase transformation studies | Isolated heating for accurate, contaminant-free results |

| Property Modification | Annealing, Sintering, Brazing, Metallizing | Controlled temperature for enhanced ductility, strength, and material bonding |

| Performance Evaluation | High-temperature strength testing, Thermal expansion measurement | Replicates extreme conditions to assess durability and mechanical properties |

Unlock Precision in Your Material Testing with KINTEK

Are you looking to enhance your laboratory's capabilities with reliable, high-temperature solutions? KINTEK specializes in advanced furnace systems tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we ensure our furnaces precisely meet your experimental requirements for material analysis, modification, and performance testing.

Contact us today to discuss how our solutions can drive efficiency and accuracy in your operations—Get in touch now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis