In essence, muffle furnaces are categorized not by brand names, but by their physical construction and their ability to control the internal atmosphere. The primary functional types are box furnaces for general heating in air, tube furnaces for processing in a controlled gas atmosphere, and vacuum furnaces for preventing oxidation entirely. These can be further classified by their temperature capabilities and physical orientation.

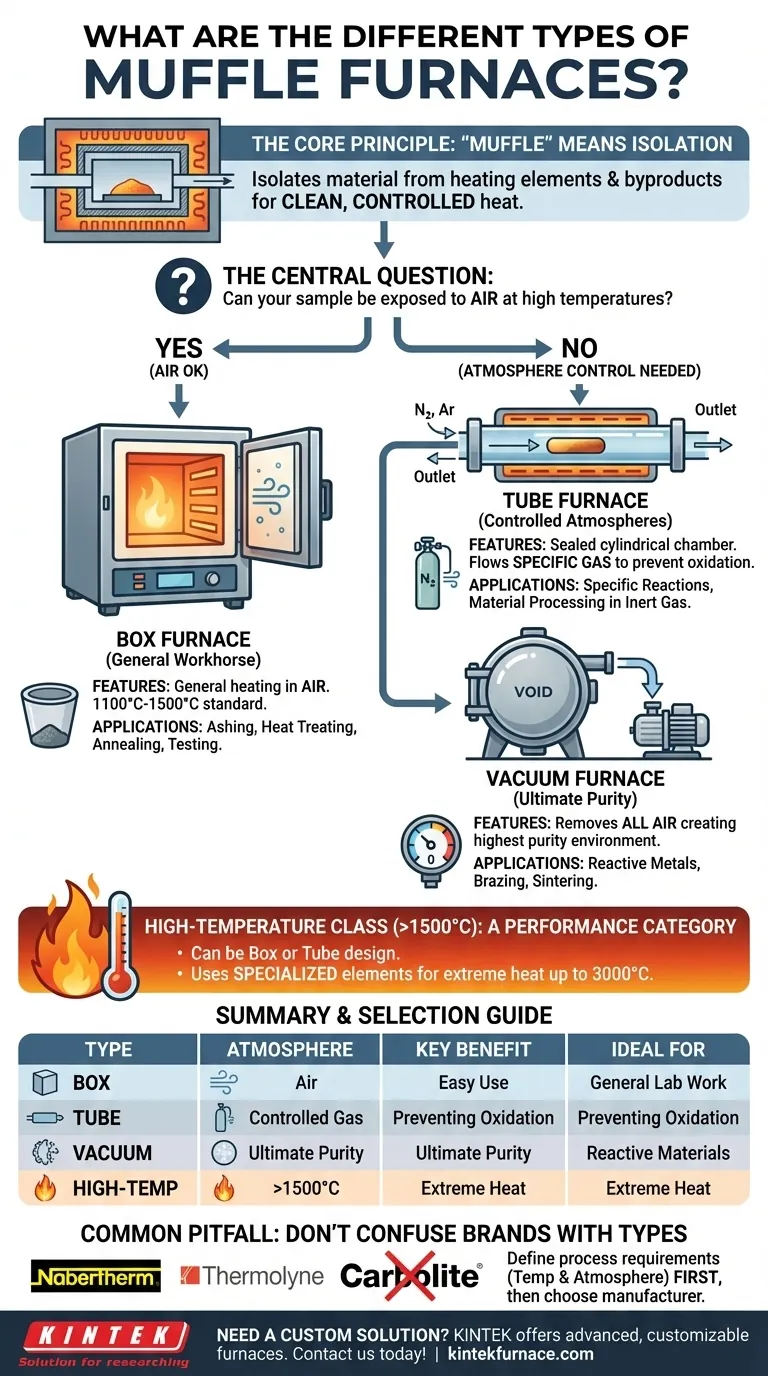

Choosing the right muffle furnace is less about the manufacturer and more about matching the furnace's design and atmospheric control to the specific requirements of your material and process. The central question is: can your sample be exposed to air at high temperatures?

The Core Principle: What "Muffle" Means

A muffle furnace is designed around a core concept: isolation. The "muffle" is the inner chamber that holds the material being heated.

This chamber separates the material from the heating elements. This prevents contamination from combustion byproducts (in fuel-fired furnaces) or direct radiation damage, ensuring a clean and highly controlled heating environment.

Modern lab furnaces are almost exclusively electric, providing exceptionally clean heat and precise temperature regulation.

The Primary Furnace Types by Function

While many features overlap, furnaces are best distinguished by their core structure and how they manage the internal atmosphere.

Box Muffle Furnaces (The General Workhorse)

This is the most common design, resembling a small box or oven. It is the standard choice for processes where heating in ambient air is acceptable.

They are ideal for general laboratory and industrial applications like ashing, heat treating, annealing, and materials testing. Most benchtop models fall into this category, typically reaching temperatures between 1100°C and 1500°C.

Tube Furnaces (For Controlled Atmospheres)

A tube furnace uses a cylindrical chamber, typically made of ceramic or quartz. Its design is ideal for creating a tightly sealed environment.

The key purpose of a tube furnace is to process materials in a controlled atmosphere. By flowing a specific gas (like nitrogen or argon) through the tube, you can prevent the heated material from reacting with oxygen in the air.

Vacuum Furnaces (For Ultimate Purity)

For materials that are extremely sensitive to oxidation or any atmospheric contamination, a vacuum furnace is required. These are essentially sealed chamber furnaces (often box or tube-like) connected to a vacuum pump.

By removing the air, these furnaces create the purest possible environment for processing reactive metals, advanced ceramics, or for applications like brazing and sintering where no surface oxidation can be tolerated.

High-Temperature Furnaces (A Performance Class)

This is less a structural type and more a performance category. Any furnace designed to operate consistently above 1500°C-1700°C is considered "high-temperature."

These furnaces can be box or tube designs but use specialized heating elements (like molybdenum disilicide) and advanced insulation to reach temperatures up to 3000°C for melting exotic metals or firing specialized ceramics.

Common Pitfalls: Confusing Brands with Types

It is critical to understand that brand names are not furnace types. Companies like Nabertherm, Thermolyne, and Carbolite Gero are respected manufacturers that produce many different types of furnaces.

For example, you can purchase a box furnace, a tube furnace, or a high-temperature furnace from any of these brands. Focusing on the brand name before defining your process needs can lead to confusion and incorrect equipment selection. Always define your required temperature and atmosphere first.

Key Features and Customizations

Once you determine the primary type you need, you can look at specific features to tailor the furnace to your workflow.

Temperature Control and Uniformity

Modern furnaces use sophisticated digital PID (Proportional-Integral-Derivative) controllers to maintain precise temperatures. Look for specifications on temperature uniformity, which describes how evenly the heat is distributed throughout the chamber.

Physical Configuration

Furnaces are available in different orientations. Horizontal models are most common, while vertical designs are useful for crucible-based applications or processes where a sample is lowered into the heat zone. Some industrial models even offer tilting or rotating systems.

Atmosphere and Exhaust Management

For box furnaces operating in air, an exhaust port is a common option to vent fumes. For tube and vacuum furnaces, you will find options for gas-loading systems with flow meters, multi-gas inlets, and advanced vacuum packages.

Making the Right Choice for Your Goal

Select your furnace based on the non-negotiable requirements of your process.

- If your primary focus is general lab work (ashing, drying, heat treating in air): A standard box muffle furnace is your most reliable and cost-effective choice.

- If your primary focus is preventing oxidation or inducing a specific reaction: You need a tube furnace with a gas control system.

- If your primary focus is processing highly sensitive or reactive materials: A vacuum furnace is essential to ensure the highest purity and prevent any contamination.

- If your primary focus is working with materials above 1500°C: You must specify a high-temperature model, regardless of its box or tube design.

Understanding these core functional differences empowers you to select a furnace based on your process requirements, not just a brand name.

Summary Table:

| Type | Key Features | Ideal Applications |

|---|---|---|

| Box Furnace | General heating in air, easy to use | Ashing, annealing, materials testing |

| Tube Furnace | Controlled gas atmosphere, sealed design | Preventing oxidation, specific reactions |

| Vacuum Furnace | No oxidation, ultimate purity | Processing reactive metals, brazing |

| High-Temperature Furnace | Operates above 1500°C, specialized elements | Melting exotic metals, firing ceramics |

Need a custom muffle furnace solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations