Operating a box-type electric furnace demands strict adherence to safety protocols to protect both the operator and the equipment. The core precautions involve conducting thorough pre-operation checks for cleanliness and power integrity, setting correct operational parameters to avoid over-temperature conditions, consistently using appropriate personal protective equipment (PPE), and being fully trained on emergency shutdown procedures.

True furnace safety is not a simple checklist, but a systematic process. It integrates machine readiness, operator preparedness, and environmental awareness into every stage of operation, from initial setup to final cool-down.

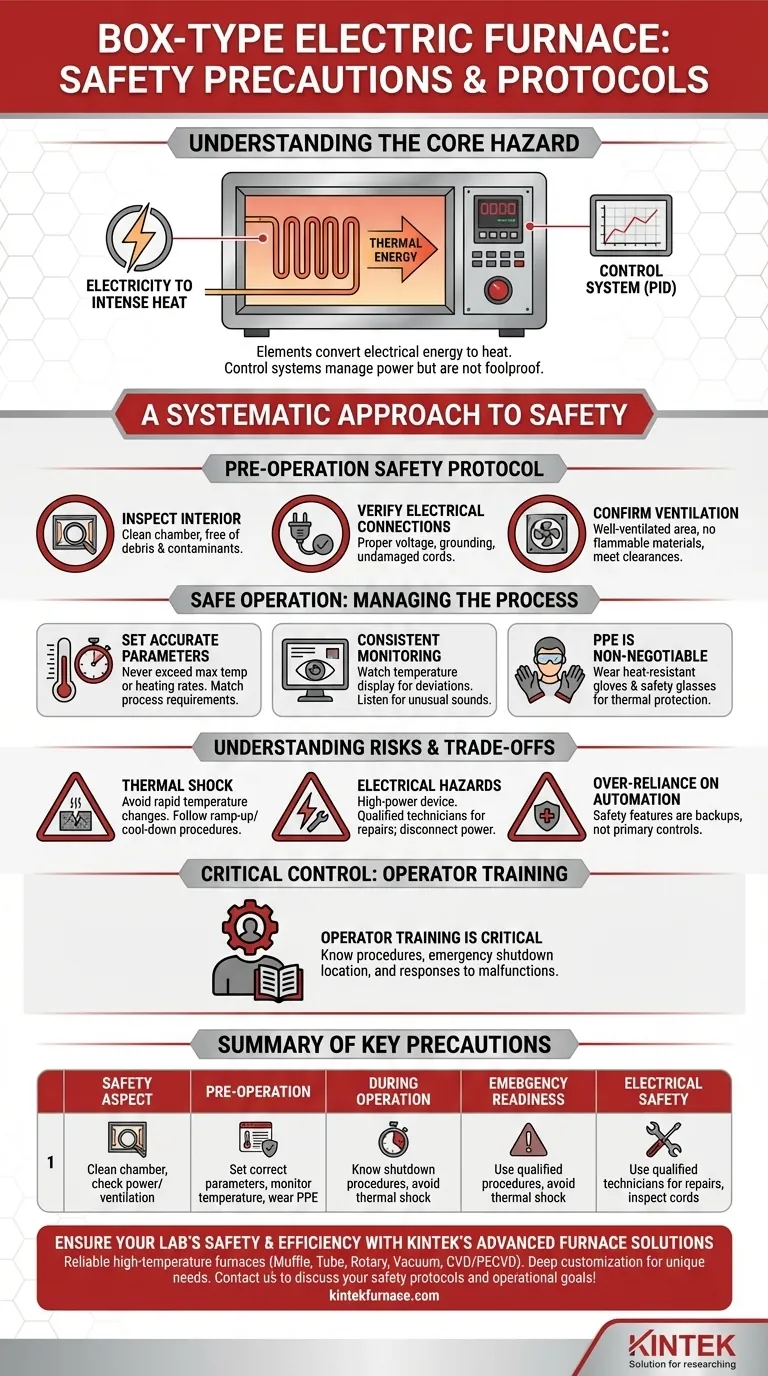

Understanding the Core Hazard

A box-type electric furnace is a simple but powerful device. Understanding its function is the first step toward using it safely.

From Electricity to Intense Heat

The furnace works by passing a high electrical current through specialized heating elements. These elements resist the flow of electricity, converting electrical energy directly into intense thermal energy.

This heat is then transferred to the materials inside the chamber through thermal conduction and radiation, allowing for precise and high-temperature processing.

The Role of the Control System

A modern furnace relies on a temperature control system, typically a PID (Proportional-Integral-Derivative) controller, to manage the power sent to the heating elements. While these systems are reliable, they are not foolproof and should not be the only line of defense.

The Pre-Operation Safety Protocol

Before you even turn the power on, a series of checks is mandatory to ensure a safe cycle.

Inspect the Furnace Interior

Always check that the furnace chamber is clean and free of any debris, residual materials, or contaminants from previous runs. Foreign objects can react unexpectedly at high temperatures, damage the furnace lining, or ruin your sample.

Verify Electrical Connections

Ensure the furnace is connected to a proper power supply with the correct voltage and grounding. Check that all power cords and connections are in good condition, with no signs of fraying or damage.

Confirm Proper Ventilation

The area around the furnace must be well-ventilated to dissipate heat. Ensure there are no flammable materials near the unit and that all clearance requirements specified by the manufacturer are met.

Safe Operation: Managing the Process

During operation, your attention and adherence to procedure are the most critical safety factors.

Setting Accurate Parameters

Set the target temperature and heating time according to your specific process requirements. Never exceed the maximum rated temperature of the furnace or the materials being heated. Avoid excessively rapid heating rates unless your process specifically requires it, as this can stress both the furnace and the sample.

Consistent Monitoring

During the heating cycle, monitor the furnace's temperature display to ensure it is following the set program. Be aware of any unusual sounds or changes in the furnace's operating atmosphere, if applicable.

Personal Protective Equipment (PPE) is Non-Negotiable

Always wear appropriate PPE when working with or near an active furnace. This includes heat-resistant gloves for handling materials and safety glasses to protect your eyes from thermal radiation and potential projectiles.

Understanding the Inherent Risks and Trade-offs

Automated features provide a safety net, but an expert operator understands the underlying risks that technology alone cannot eliminate.

Thermal Shock and Material Failure

Placing a cold load into a hot furnace or removing a hot load into a cool environment can cause thermal shock, leading to cracking or failure of your material or even the furnace's ceramic components. Always follow recommended ramp-up and cool-down procedures.

Electrical Hazards

The furnace is a high-power electrical device. All maintenance and repairs on electrical components must be performed by a qualified technician with the power disconnected at the source.

Over-reliance on Automated Protection

Modern furnaces include safety features like over-temperature protection that cut power if a set limit is exceeded. While critical, these are backup systems. Relying on them as your primary method of control is poor practice and indicates a flaw in your process parameters.

Operator Training as a Critical Control

The single most common point of failure is inadequate operator training. Every user must be familiar with the furnace's specific operating procedures, the location of the emergency shutdown button, and the appropriate response to any potential malfunction.

Making the Right Choice for Your Goal

By integrating these precautions into a formal protocol, you can ensure safe and effective operation tailored to your specific objective.

- If your primary focus is operator safety: Prioritize comprehensive training on PPE usage, emergency shutdown protocols, and the risks of thermal exposure.

- If your primary focus is equipment longevity: Emphasize routine maintenance, pre-operation cleanliness checks, and strict adherence to the furnace's maximum temperature limits.

- If your primary focus is process reliability: Focus on precise parameter setting, consistent monitoring during the cycle, and understanding the thermal properties of your materials to prevent failure.

A systematic approach to safety transforms the furnace from a potential hazard into a predictable and powerful tool.

Summary Table:

| Safety Aspect | Key Precautions |

|---|---|

| Pre-Operation | Clean chamber, check power/ventilation, verify connections |

| During Operation | Set correct parameters, monitor temperature, wear PPE |

| Emergency Readiness | Know shutdown procedures, avoid thermal shock, ensure training |

| Electrical Safety | Use qualified technicians for repairs, inspect cords |

Ensure your lab's safety and efficiency with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability tailors each solution to your unique experimental needs, enhancing precision and durability. Contact us today to discuss how we can support your safety protocols and operational goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide