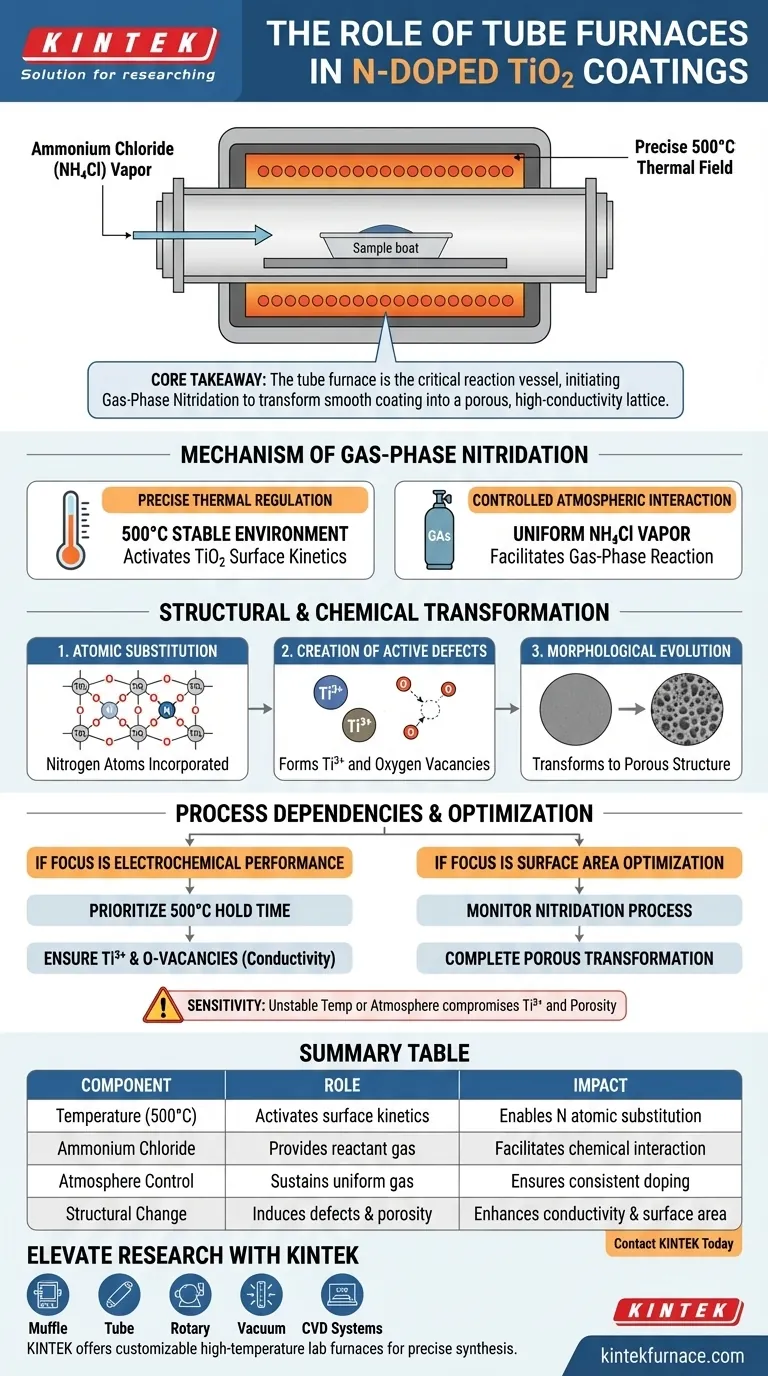

The tube furnace serves as the critical reaction vessel for synthesizing nitrogen-doped titanium dioxide coatings. It establishes a precise temperature field, typically maintained at 500 °C, and sustains the specific atmospheric environment necessary for the chemical reaction between the titanium dioxide coating and ammonium chloride.

Core Takeaway The tube furnace does not merely heat the sample; it facilitates a gas-phase nitridation process that fundamentally alters the material's atomic structure. By enabling the introduction of nitrogen atoms, it transforms a smooth coating into a porous, high-conductivity lattice essential for advanced performance.

The Mechanism of Gas-Phase Nitridation

Precise Thermal Regulation

The furnace provides a stable, high-temperature environment mandated by the reaction kinetics.

Maintained specifically at 500 °C, this thermal energy is required to activate the surface of the titanium dioxide. Without this precise heat application, the chemical interaction with the dopant source cannot initiate.

Controlled Atmospheric Interaction

The equipment ensures the coating is exposed to a consistent concentration of reactant gas.

The furnace contains the ammonium chloride vapor, facilitating its reaction with the solid titanium dioxide coating. This controlled gas-phase environment allows for uniform exposure across the material's surface.

Structural and Chemical Transformation

Atomic Substitution

The primary function of this thermal process is the strategic introduction of nitrogen.

Under these conditions, nitrogen atoms are successfully incorporated into the titanium oxide lattice. This doping is the root cause of the material's altered properties.

Creation of Active Defects

The high-temperature nitridation induces specific chemical changes within the crystal structure.

The process leads to the formation of trivalent titanium (Ti3+) and oxygen vacancies. these defects are critical for enhancing the material's electronic and ionic behavior.

Morphological Evolution

The physical architecture of the coating changes drastically during the furnace treatment.

The initial coating, which is typically smooth, is transformed into a porous structure. This increased porosity creates pathways that significantly enhance high ionic conductivity.

Understanding the Process Dependencies

Sensitivity to Conditions

The success of this process relies heavily on the stability of the tube furnace environment.

If the temperature deviates from the 500 °C target or the ammonium chloride atmosphere is inconsistent, the formation of Ti3+ and oxygen vacancies may be compromised. The transformation from smooth to porous is a direct result of these specific parameters being met.

Optimizing Material Performance

Based on the transformative capabilities of the tube furnace, here is how to view the process relative to your engineering goals:

- If your primary focus is electrochemical performance: Prioritize the precise 500 °C hold time to ensure the generation of sufficient Ti3+ and oxygen vacancies for conductivity.

- If your primary focus is surface area optimization: Monitor the nitridation process to ensure the complete transformation from a smooth surface to the desired porous morphology.

The tube furnace is the enabling tool that converts a standard oxide coating into a highly conductive, chemically active component.

Summary Table:

| Process Component | Role in Nitridation | Impact on TiO2 Coating |

|---|---|---|

| Temperature (500°C) | Activates surface kinetics | Enables atomic substitution of Nitrogen |

| Ammonium Chloride | Provides reactant gas vapor | Facilitates gas-phase chemical interaction |

| Atmosphere Control | Sustains uniform gas concentration | Ensures consistent doping across lattice |

| Structural Change | Induces oxygen vacancies | Transforms smooth surface to porous morphology |

Elevate Your Material Research with KINTEK

Precision is the difference between a standard coating and a high-performance nitrogen-doped lattice. KINTEK provides the advanced heating solutions required for sensitive gas-phase reactions. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific temperature and atmospheric requirements.

Whether you are focusing on electrochemical performance or surface area optimization, our high-temperature lab furnaces deliver the stability needed to generate critical Ti3+ defects and oxygen vacancies. Contact KINTEK today to discuss your unique laboratory needs and discover how our equipment can streamline your synthesis process.

Visual Guide

References

- Xiangqi Liu, Mark H. Rümmeli. LiF‐Dominated SEI Formation via a Lychee‐Like Primary Interphase for Fast‐Charging Natural Graphite Anodes. DOI: 10.1002/smll.202504255

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the specific operational benefits of tube furnace cracking? Unlock Efficiency and Precision in Material Processing

- How does a Tube Furnace facilitate precise control during CVD? Master Stoichiometry and Phase Purity

- What is the significance of a rapid quenching device at the bottom of a lab tube furnace? Capture High-Temp Snapshot

- What is the function of the pre-oxidation process conducted in a tube furnace? Stabilize Lignin for Carbon Fibers.

- What is the purpose of insulation in a 70mm tube furnace? Ensure Precision and Efficiency in Your Lab

- What is the primary function of a tube furnace in CVD synthesis of carbon nanotubes? Achieve Precision Thermal Control

- What are the key components of a tubular furnace? Unlock Precision in High-Temperature Processing

- Why is a continuous nitrogen flow required in a closed tube furnace during the solid-phase synthesis of LiMnO2 precursors?