At its core, a tubular furnace is an integrated system built around five key components. These are the furnace tube, heating elements, a temperature control system, the furnace body with insulation, and often a gas or vacuum system to control the internal atmosphere. Together, these parts create a highly controlled environment for precise thermal processing of materials.

A tubular furnace is more than just a high-temperature oven. It is a precision instrument where each component—from the reaction tube to the control system—is deliberately chosen and integrated to achieve a specific, stable, and uniform thermal environment.

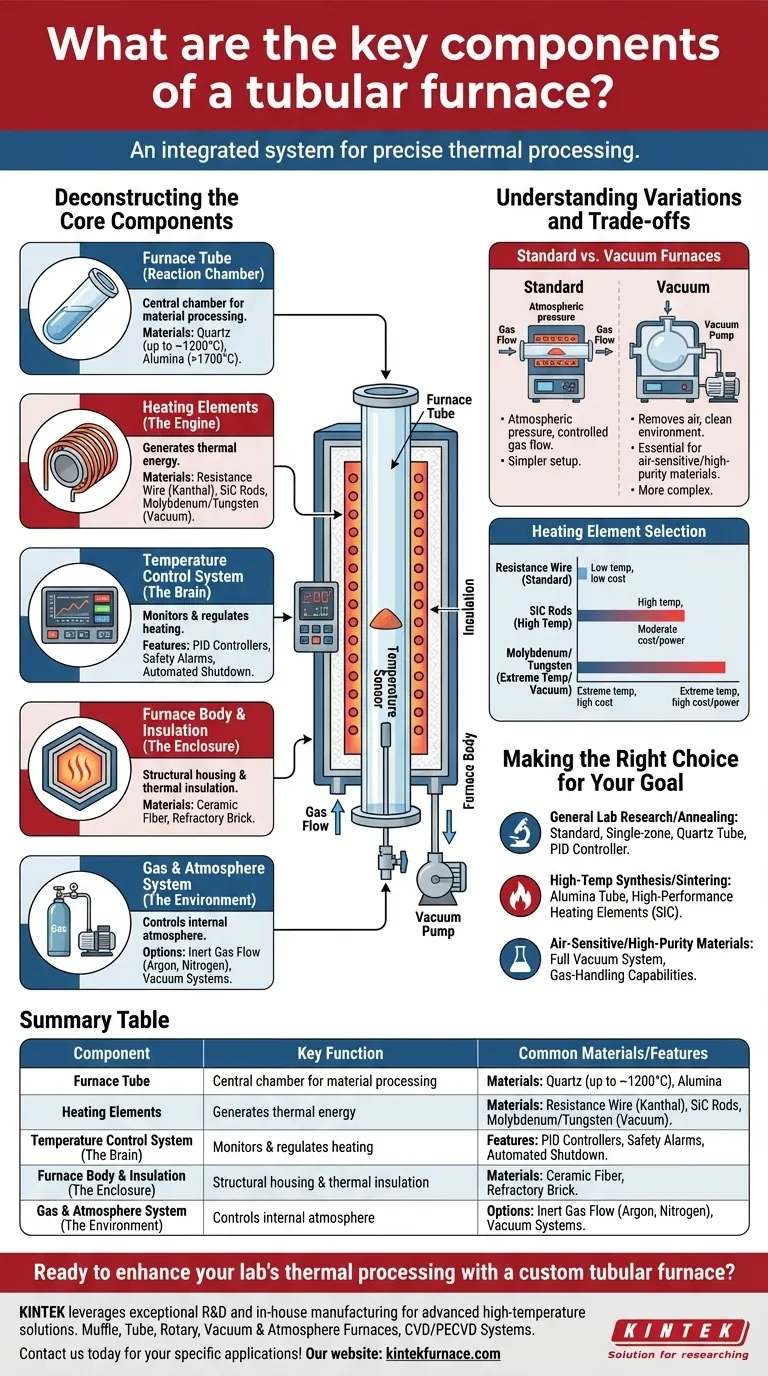

Deconstructing the Core Components

To understand how a tubular furnace achieves its precision, we must look at how its primary components function as a cohesive system. Each part serves a distinct but interconnected purpose.

The Furnace Tube (The Reaction Chamber)

The furnace tube is the central component where the material processing takes place. It is a cylindrical chamber designed to withstand extreme temperatures.

The material of this tube is critical. Quartz is common for lower to moderate temperatures (up to ~1200°C) and offers the benefit of being transparent. For higher temperatures, opaque ceramic materials like alumina are used, capable of handling temperatures well above 1700°C.

The Heating Elements (The Engine)

The heating elements are responsible for generating the thermal energy. They are typically arranged around the exterior of the furnace tube to provide uniform, indirect heat.

These elements are made from materials like resistance wire (e.g., Kanthal) for standard applications or silicon carbide (SiC) rods for higher temperatures. In specialized vacuum furnaces, elements made of molybdenum or tungsten are used for even more extreme heat requirements.

The Temperature Control System (The Brain)

This is arguably the most critical component for ensuring process accuracy and repeatability. The control system monitors and regulates the output of the heating elements.

Modern systems use sophisticated PID (Proportional-Integral-Derivative) controllers to minimize temperature overshoot and maintain stability within a degree. They often include safety features like over-temperature alarms and automated shutdown procedures.

The Furnace Body & Insulation (The Enclosure)

The furnace body provides the structural housing for all the components. Its primary functional role is thermal insulation.

High-quality ceramic fiber or refractory brick insulation is packed between the heating elements and the outer shell. This ensures heat is directed into the furnace tube, improving energy efficiency and keeping the exterior safe to touch.

The Gas & Atmosphere System (The Environment)

Many processes require a specific atmosphere other than ambient air. This system allows for precise control over the environment inside the tube.

It can range from a simple port for flowing inert gas like argon or nitrogen to a complex vacuum system. A vacuum system, consisting of pumps and sealed flanges, removes air to prevent oxidation and contamination during processing.

Understanding Variations and Trade-offs

Not all tubular furnaces are the same. The specific components chosen are dictated by the intended application, creating important trade-offs in capability, complexity, and cost.

Standard vs. Vacuum Furnaces

A standard tubular furnace operates at atmospheric pressure, often with a controlled flow of gas. A vacuum furnace is a more complex variant that includes a pumping system to remove air from the chamber.

The primary advantage of a vacuum is creating a clean, contamination-free environment, which is essential for processing air-sensitive or high-purity materials. This capability comes at the cost of a more complex and expensive setup.

Heating Element Selection

The choice of heating element directly determines the furnace's maximum operating temperature. Standard resistance wires are cost-effective but limited in range.

Upgrading to silicon carbide or molybdenum elements significantly increases the temperature ceiling but also the cost and power requirements of the system.

Tube Material and Diameter

The furnace tube itself presents a trade-off. Quartz allows you to visually monitor the process but has a lower temperature limit and can become brittle. Alumina is more robust at high temperatures but is opaque.

The diameter of the tube also matters. A smaller diameter generally provides better temperature uniformity, while a larger diameter allows for greater sample throughput.

Making the Right Choice for Your Goal

Understanding these components allows you to select a furnace configuration that directly matches your processing needs.

- If your primary focus is general lab research or annealing: A standard, single-zone furnace with a quartz tube and a reliable PID controller is often the most practical and cost-effective choice.

- If your primary focus is high-temperature synthesis or sintering: You must prioritize a furnace with an alumina tube and high-performance heating elements like silicon carbide (SiC).

- If your primary focus is processing air-sensitive or high-purity materials: A furnace equipped with a full vacuum system and gas-handling capabilities is non-negotiable.

Ultimately, viewing the tubular furnace as an adaptable system of interchangeable parts empowers you to specify the precise tool for your scientific or industrial objective.

Summary Table:

| Component | Key Function | Common Materials/Features |

|---|---|---|

| Furnace Tube | Reaction chamber for material processing | Quartz (up to ~1200°C), Alumina (above 1700°C) |

| Heating Elements | Generate thermal energy | Resistance wire (e.g., Kanthal), SiC rods, Molybdenum/Tungsten for high temps |

| Temperature Control System | Monitor and regulate temperature | PID controllers, safety alarms, automated shutdown |

| Furnace Body & Insulation | Structural housing and thermal insulation | Ceramic fiber, refractory brick |

| Gas & Atmosphere System | Control internal environment | Inert gas flow (e.g., Argon, Nitrogen), vacuum systems |

Ready to enhance your lab's thermal processing with a custom tubular furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in research, synthesis, or handling air-sensitive materials, we can help you achieve precise, stable thermal environments. Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety