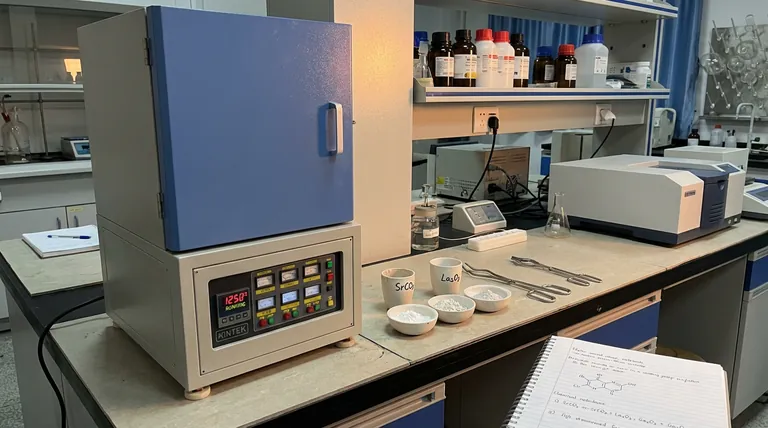

The primary role of a muffle furnace in this context is to facilitate a high-temperature solid-state reaction. Specifically, it maintains a stable environment at 1250°C for a duration of three days. This sustained heat forces raw material powders—strontium carbonate (SrCO3), lanthanum oxide (La2O3), and gallium oxide (Ga2O3)—to diffuse and react chemically, resulting in the uniform polycrystalline material required for subsequent crystal growth.

Core Takeaway The muffle furnace serves as a precision stability chamber rather than a simple heating element. Its critical function is to hold a constant 1250°C temperature long enough (72 hours) to drive complete atomic diffusion, transforming disparate raw powders into a pure-phase, homogeneous precursor essential for high-quality single-crystal production.

The Mechanism of Precursor Synthesis

Creating the Solid-State Reaction Environment

To synthesize Nd:SrLaGaO4 precursors, simple heating is insufficient; the process requires a solid-state reaction.

The muffle furnace provides a strictly controlled thermal field that allows solid materials to react without fully melting into a liquid phase initially. The furnace must maintain a constant temperature of 1250°C. This specific thermal energy is required to break the chemical bonds of the raw ingredients and facilitate the formation of the new crystal lattice.

Facilitating Atomic Diffusion

The synthesis relies on the physical mixing and chemical bonding of specific raw powders: SrCO3, La2O3, and Ga2O3.

Because these materials are solids, they do not mix as easily as liquids or gases. The muffle furnace facilitates diffusion, the process where atoms move from areas of high concentration to low concentration. By sustaining the high temperature for three full days, the furnace ensures that the atoms have sufficient time and energy to migrate across particle boundaries and integrate thoroughly.

Ensuring Phase Purity and Homogeneity

The ultimate goal of this thermal treatment is uniformity.

If the temperature fluctuates or the duration is cut short, the material may contain unreacted raw powders or secondary phases. The stable environment of the muffle furnace ensures the production of pure-phase, uniform polycrystalline materials. These precursors act as the high-quality "feedstock" necessary for growing the final single crystals.

Understanding the Trade-offs

Energy and Time Intensity

The synthesis of Nd:SrLaGaO4 precursors is an energy-intensive process. Maintaining 1250°C for 72 hours requires significant power consumption. This makes the process costly and time-consuming compared to low-temperature synthesis methods.

Batch Process Limitations

Muffle furnaces operate as batch reactors. Once the three-day cycle begins, the process cannot be interrupted to add more material or adjust the composition without restarting the thermal cycle. This requires precise measurement of raw materials (SrCO3, La2O3, Ga2O3) before the cycle begins, as errors cannot be corrected mid-process.

Critical Considerations for Synthesis

Making the Right Choice for Your Goal

- If your primary focus is Phase Purity: Ensure your furnace can maintain 1250°C with minimal fluctuation (< ±1°C) to prevent the formation of secondary, unwanted crystal phases.

- If your primary focus is Material Homogeneity: Prioritize the full three-day soaking period; shortening this duration will likely result in incomplete diffusion and inconsistent precursor quality.

Success in growing Nd:SrLaGaO4 single crystals depends entirely on the uniformity of the polycrystalline precursors synthesized in the muffle furnace.

Summary Table:

| Parameter | Specification | Purpose in Synthesis |

|---|---|---|

| Temperature | 1250°C | Facilitates solid-state reaction and bond breaking |

| Duration | 72 Hours (3 Days) | Ensures complete atomic diffusion and homogeneity |

| Raw Materials | SrCO3, La2O3, Ga2O3 | Chemical ingredients for the precursor lattice |

| Output State | Polycrystalline | Pure-phase feedstock for single-crystal growth |

Elevate Your Crystal Synthesis with KINTEK Precision

High-quality Nd:SrLaGaO4 single crystals demand a perfectly uniform precursor. KINTEK provides the industry-leading thermal solutions required for rigorous 72-hour solid-state reactions. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your specific lab requirements.

Ready to ensure absolute phase purity in your materials? Contact KINTEK today to discuss your custom furnace needs

Visual Guide

References

- Shanshan Fang, He‐Rui Wen. Growth, Structure, and Spectroscopic Properties of a Disordered Nd:SrLaGaO4 Laser Crystal. DOI: 10.3390/cryst14020174

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the design feature of the furnace chamber and frame in a muffle furnace? Discover the Key to Durability

- In which industries are muffle furnaces commonly used? Essential for Clean High-Temp Processing

- What role does a muffle furnace play in refractory bricks? Enhance Performance and Durability Testing

- How do muffle furnaces contribute to energy efficiency? Discover Advanced Heat Management for Labs

- What are the advantages of repeated calcination-reconstruction cycles for CuO nanoparticles? Master Precision Control

- What comprises the working chamber of a box type resistance furnace? Discover the Core Components for Efficient High-Temp Operations

- What are the primary functions of industrial muffle furnaces in the thermal stabilization of metal-lignin complexes?

- How does a high-temperature box furnace contribute to the sintering of doped zirconate ceramics? Achieve 94% Density