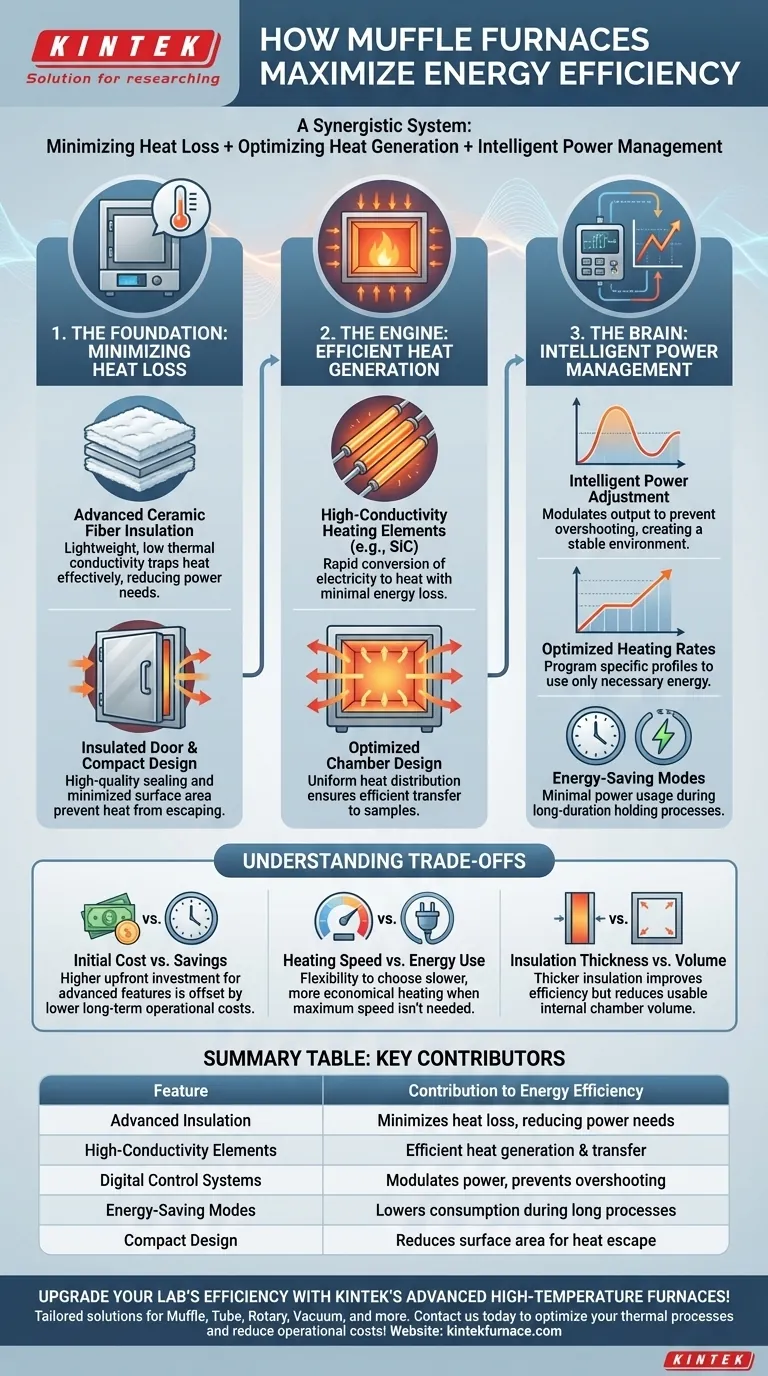

At its core, a muffle furnace's energy efficiency is not the result of a single component, but a synergistic system. This system is designed to minimize heat loss, optimize heat generation, and intelligently manage power consumption. The key contributors are advanced insulation materials, highly conductive heating elements, and sophisticated digital controls that work in concert to reduce wasted energy.

The central principle of muffle furnace efficiency is twofold: first, aggressively retain the heat you generate through superior insulation, and second, use intelligent controls to apply only the precise amount of energy needed to reach and maintain the target temperature.

The Foundation: Minimizing Heat Loss

The most significant source of energy waste in any furnace is heat escaping into the surrounding environment. Modern muffle furnaces combat this with a multi-layered defense.

Advanced Ceramic Fiber Insulation

Older furnaces used heavy, dense refractory bricks. Modern designs use lightweight ceramic fiber insulation, which has exceptionally low thermal conductivity.

This material acts like a high-tech blanket, trapping heat inside the chamber far more effectively and reducing the power needed to maintain temperature.

Insulated Door and Compact Design

A furnace is only as good as its weakest point. The door is a primary source of heat loss, so modern furnaces use the same high-quality fiber materials to insulate the door assembly.

Furthermore, the overall design often features thick walls and a compact footprint, which minimizes the external surface area and, therefore, the potential for heat to escape.

The Engine: Efficient Heat Generation and Transfer

Once heat is contained, the next step is generating it and delivering it to the sample efficiently.

High-Conductivity Heating Elements

Modern furnaces often use silicon carbide (SiC) heating elements. These elements are prized for their excellent thermal conductivity.

This means they convert electricity into heat very quickly and transfer that heat to the furnace chamber with minimal energy loss, contributing to faster heating rates.

Optimized Chamber Design

The "muffle" itself—the inner chamber that holds the sample—is designed to isolate the material from contaminants from the heating elements.

Crucially, it is also engineered to absorb and distribute the heat from the elements evenly, ensuring superior temperature uniformity and efficient heat transfer to your samples.

The Brain: Intelligent Power Management

Brute force heating is inefficient. The real gains in modern furnaces come from smart, digital control systems.

Intelligent Power Adjustment

Instead of simply running at full power until the setpoint is reached, a digital controller modulates the power output. As the furnace approaches the target temperature, the controller reduces the power.

This prevents overshooting the temperature, a common source of wasted energy, and creates a much more stable thermal environment.

Optimized Heating Rates

The ability to program specific heating profiles allows you to use only the energy necessary for your experiment. You can set a slower ramp rate for a delicate process, avoiding the high energy consumption of a "full-throttle" heating cycle.

Energy-Saving Modes

For long-duration processes like ashing or annealing, many furnaces feature energy-saving or standby modes.

Once the target temperature is stable, these modes use minimal power—just enough to counteract the small amount of heat loss—to hold the temperature steady for hours, drastically reducing overall energy use.

Understanding the Trade-offs

While modern furnaces offer significant efficiency gains, it's important to understand the associated compromises.

Initial Cost vs. Operational Savings

Furnaces equipped with advanced insulation, high-end elements, and sophisticated digital controllers typically have a higher upfront purchase price. This initial investment is offset by lower long-term operational costs due to reduced electricity consumption.

Heating Speed vs. Energy Use

Rapid heating is a key feature, but it is also the most energy-intensive mode of operation. The efficiency benefit comes from having the flexibility to choose a slower, more economical heating rate when maximum speed is not required.

Insulation Thickness vs. Chamber Volume

Thicker insulation is superior for energy efficiency. However, for a given external furnace size, more insulation means less usable internal chamber volume. This is a fundamental design trade-off between thermal performance and capacity.

Making the Right Choice for Your Application

Selecting the right furnace involves matching its features to your primary laboratory or industrial goal.

- If your primary focus is high-throughput sample processing: Prioritize a model with rapid heating/cooling cycles and an intelligent controller that can quickly stabilize temperatures.

- If your primary focus is long-duration heat treatment or ashing: Look for superior ceramic fiber insulation and proven energy-saving modes to minimize power consumption over extended runs.

- If your primary focus is precise materials research: Emphasize furnaces with excellent temperature uniformity and programmable controls that ensure repeatable, accurate thermal profiles.

Ultimately, the energy efficiency of a modern muffle furnace is achieved when its physical design and intelligent controls work together to deliver precise heat only when and where it is needed.

Summary Table:

| Feature | Contribution to Energy Efficiency |

|---|---|

| Advanced Ceramic Fiber Insulation | Minimizes heat loss, reducing power needs |

| High-Conductivity Heating Elements | Efficient heat generation and transfer |

| Digital Control Systems | Modulates power to prevent overshooting and optimize usage |

| Energy-Saving Modes | Lowers power consumption during long processes |

| Compact Design | Reduces surface area for heat escape |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering energy savings and superior performance. Contact us today to discuss how we can optimize your thermal processes and reduce operational costs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure