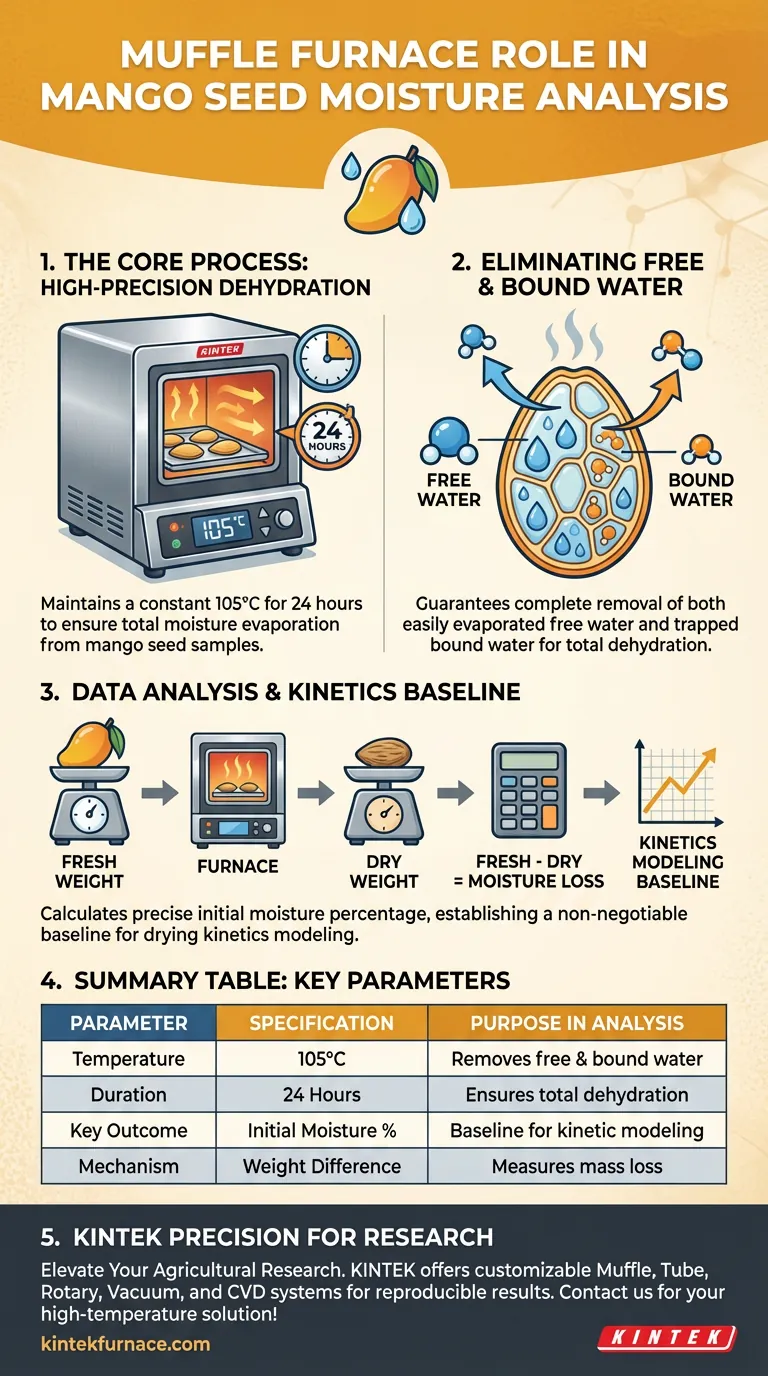

In the context of mango seed analysis, the muffle furnace functions as a high-precision dehydration tool. It executes a rigorous, constant drying procedure at 105 degrees Celsius for 24 hours. This thermal treatment ensures the total evaporation of moisture, allowing researchers to calculate the initial moisture content by measuring the exact weight difference between the fresh and dried samples.

The muffle furnace ensures the complete removal of both bound and free water through high-precision temperature control. This measurement establishes the initial moisture percentage, which acts as the non-negotiable baseline for valid drying kinetics modeling.

The Mechanics of Total Moisture Removal

Constant High-Temperature Drying

To determine moisture content accurately, the environment must be stable. The muffle furnace is utilized specifically for its ability to maintain a constant temperature of 105 degrees Celsius.

This temperature is sustained continuously for a standard duration of 24 hours. This ensures that the heating process is thorough and uniform across all seed samples.

Eliminating Free and Bound Water

Mango seeds contain water in two states: free water (easily evaporated) and bound water (trapped within the cellular structure). A standard drying method might leave bound water behind, skewing results.

The muffle furnace’s high-precision control guarantees that both bound and free water are completely removed. This total dehydration is the only way to determine the absolute dry weight of the seed.

The Role in Data Analysis and Modeling

Calculating Precise Weight Differences

The fundamental output of this process is the weight difference. By comparing the mass of the mango seed before it enters the furnace and after the 24-hour cycle, researchers derive the moisture loss.

This data point allows for the calculation of the precise initial moisture percentage. This figure is not an estimate; it is an empirically derived value representing the total water content.

Establishing a Baseline for Kinetics

Scientific modeling requires an accurate starting point. The initial moisture content determined by the muffle furnace serves as the critical baseline.

Subsequent drying kinetics modeling—which predicts how seeds will dry under different conditions—relies entirely on this baseline. If the initial value is incorrect due to incomplete drying, the entire model becomes invalid.

Understanding the Methodological Requirements

The Necessity of Time

The muffle furnace method is not a rapid test. It requires a full 24-hour cycle to be effective.

Shortcutting this duration risks leaving bound water inside the seed, which would result in an understated moisture content reading.

The Requirement for Thermal Stability

Precision is the primary asset of the muffle furnace. The process relies on the equipment's ability to hold 105 degrees Celsius without significant fluctuation.

Any deviation in temperature control could either fail to remove all water (if too low) or potentially degrade the dry matter (if too high), compromising the "constant weight" calculation.

Making the Right Choice for Your Goal

To ensure your mango seed analysis yields valid scientific data, apply the muffle furnace method with strict adherence to the reference parameters.

- If your primary focus is accurate data collection: Ensure the furnace is calibrated to maintain exactly 105°C for the full 24 hours to remove all traces of bound water.

- If your primary focus is process modeling: Use the resulting weight difference to establish a precise initial moisture baseline, as this is the foundation for all subsequent drying kinetics equations.

Precision in the initial heating stage is the prerequisite for accuracy in the final model.

Summary Table:

| Parameter | Specification | Purpose in Mango Seed Analysis |

|---|---|---|

| Temperature | 105°C | Ensures constant heat to remove free and bound water. |

| Duration | 24 Hours | Guaranteed time for total dehydration of cellular structures. |

| Key Outcome | Initial Moisture % | Establishes the non-negotiable baseline for kinetic modeling. |

| Mechanism | Weight Difference | Measures mass loss between fresh and absolute dry samples. |

Elevate Your Agricultural Research with KINTEK Precision

Accuracy in drying kinetics begins with the right thermal equipment. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific lab requirements.

Whether you are determining moisture content in biomass or developing complex material models, our lab furnaces provide the thermal stability needed for reproducible scientific results. Contact us today to find the perfect high-temperature solution for your lab!

Visual Guide

References

- Getachew D. Gebre, J.M. Marchetti. Drying kinetics and mathematical modeling of seeds of two mango varieties at different temperatures and with different pretreatments. DOI: 10.1002/bbb.2611

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of an industrial muffle furnace in converting microalgae into cobalt oxide nanomaterials?

- What specialized processes utilize box furnaces? Discover Versatile Heat Treatment Solutions

- What are the operational advantages of box type high-temperature resistance furnaces? Achieve Reliable, User-Friendly Thermal Processing

- What is the process logic of a muffle furnace for tungsten oxynitride thin films? Optimize Your Thermal Cycle

- What steps are involved in starting a muffle furnace? Master Safe and Efficient Operation

- Why is a box muffle furnace required for In2O3 nanofibers? Expert Synthesis & Pre-Oxidation Guide

- What are the common transport methods used in Muffle Furnaces? Choose the Right System for Your Lab

- What is the defining characteristic of a muffle furnace? Achieve Pure, Uniform Heating for Your Lab