To start a muffle furnace, first ensure the power supply is connected correctly. Place your sample inside the chamber, close the door, and set your desired operating temperature using the controller. Finally, turn on the main power switch and monitor the indicator lights, which signal when the furnace is heating up and when it has reached a constant temperature.

A muffle furnace is more than just a high-temperature oven; it is a precision instrument designed for creating an exceptionally clean and controlled heating environment. Understanding its core components and safety protocols is as crucial as knowing which buttons to press.

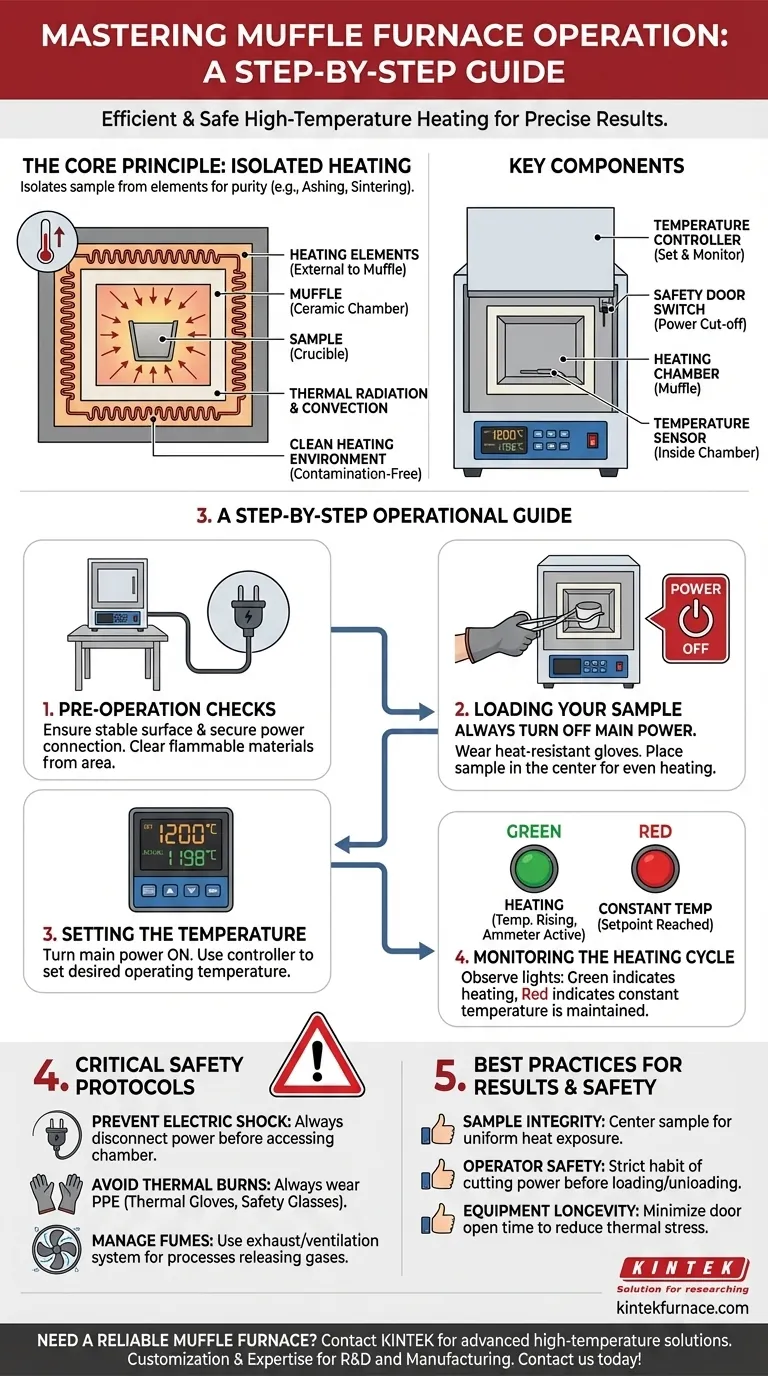

Understanding How a Muffle Furnace Works

To operate a furnace correctly, you must first understand its fundamental design. Its purpose is to heat a material without any contact from combustion byproducts or direct flames.

The Core Principle: Isolated Heating

A muffle furnace's defining feature is its internal chamber, or "muffle," which is typically made of a ceramic material.

This chamber isolates the sample from the heating elements, creating a clean environment free from contamination. This is essential for processes like ashing, sintering, or heat-treating where purity is critical.

Heat Transfer and Distribution

The furnace generates heat using electric resistance heating elements (like Kanthal or Nichrome) that wrap around the outside of the muffle chamber.

Heat is transferred to the sample through thermal radiation and convection, ensuring a uniform temperature is distributed throughout the chamber. High-quality insulation minimizes heat loss, allowing the furnace to reach and maintain very high temperatures efficiently.

Key Components You Interact With

- Heating Chamber (Muffle): The insulated box where you place your sample.

- Temperature Controller: The digital or analog interface used to set and monitor the temperature.

- Temperature Sensors: Devices like thermocouples inside the chamber that feed real-time temperature data back to the controller.

- Safety Door Switch: A mechanism on many models that automatically cuts power to the heating elements when the door is opened.

A Step-by-Step Operational Guide

Following a precise procedure ensures both accurate results and personal safety. Do not deviate from these fundamental steps.

Pre-Operation Checks

Before turning anything on, confirm the furnace is on a stable, level surface and that the power cord is securely connected to a suitable outlet. Ensure the area around the furnace is clear of flammable materials.

Loading Your Sample

Always turn off the main power supply before opening the door to load or unload a sample. This prevents any risk of electric shock.

Using heat-resistant gloves, place your crucible or sample in the center of the furnace floor. Arrange multiple samples neatly for even heating. Close the door securely and as quickly as possible to prevent heat loss and thermal shock to the chamber.

Setting the Temperature

With the door closed, turn the main power switch on. Use the temperature controller to adjust the setpoint to your desired operating temperature.

Monitoring the Heating Cycle

Observe the furnace's control panel. A green indicator light typically signals that the heating elements are active and the temperature is rising. An ammeter, if present, will show a current draw during this phase.

When the furnace reaches the setpoint, a red indicator light often illuminates, signaling the controller is now maintaining a constant temperature.

Critical Safety Protocols

A muffle furnace operates at extreme temperatures, making safety the primary concern. Ignoring these protocols can lead to severe injury or equipment damage.

Preventing Electric Shock

The most important rule is to always disconnect power before reaching into the chamber. Even if your model has a safety door switch, treating the furnace as live unless the main power is off is the safest practice.

Avoiding Thermal Burns

The exterior surfaces and especially the door of the furnace can become extremely hot. Always wear appropriate personal protective equipment (PPE), including thermal gloves and safety glasses, when handling samples or operating the furnace.

Managing Fumes and Contamination

Some processes release fumes or gases as the sample is heated. If your furnace is equipped with an exhaust port or ventilation system, ensure it is functioning correctly to safely vent these byproducts away from the workspace.

Best Practices for Consistent and Safe Results

Applying these principles will help you achieve reliable outcomes while ensuring safety and prolonging the life of the equipment.

- If your primary focus is sample integrity: Always place the sample in the center of the muffle to ensure the most uniform heat exposure.

- If your primary focus is operator safety: Make it a strict habit to cut all power before loading or unloading and always wear proper thermal gloves.

- If your primary focus is equipment longevity: Minimize the amount of time the furnace door is open to reduce thermal stress on the chamber and insulation.

By treating the muffle furnace with respect and understanding its design, you can confidently achieve precise and repeatable results.

Summary Table:

| Step | Key Actions | Purpose |

|---|---|---|

| Pre-Operation Checks | Ensure stable surface, power connection, clear area | Safety and readiness |

| Loading Samples | Turn off power, use gloves, center sample in chamber | Prevent contamination and ensure even heating |

| Setting Temperature | Turn on power, adjust controller to desired setpoint | Achieve precise heating conditions |

| Monitoring Cycle | Watch indicator lights (e.g., green for heating, red for constant) | Track progress and maintain temperature |

| Safety Protocols | Disconnect power before access, wear PPE, manage fumes | Prevent injury and equipment damage |

Need a reliable muffle furnace for your lab? KINTEK specializes in advanced high-temperature solutions, including Muffle, Tube, and Rotary Furnaces, with deep customization to meet your unique experimental needs. Our expertise in R&D and in-house manufacturing ensures precise, safe, and efficient performance. Contact us today to discuss how we can enhance your laboratory's capabilities!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites