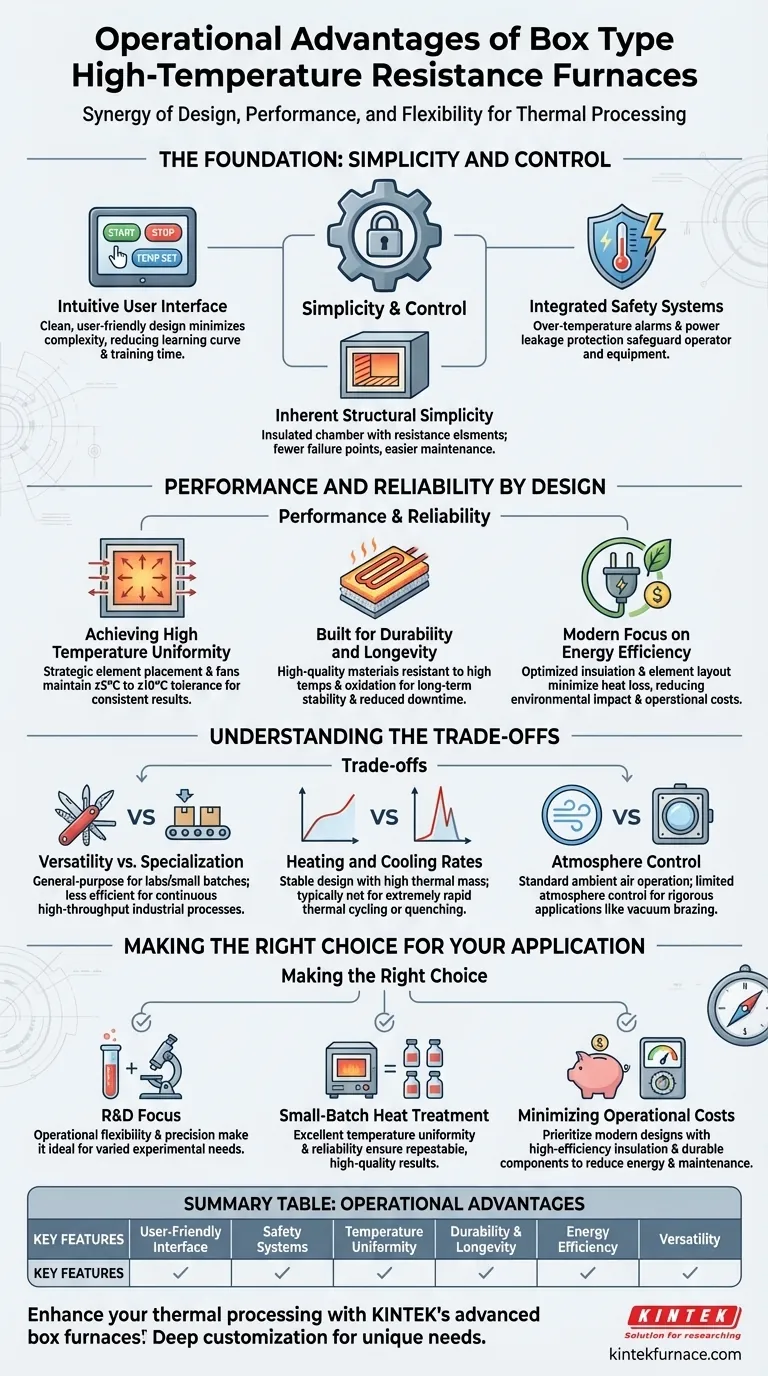

From an operational standpoint, box-type high-temperature resistance furnaces are valued for their straightforward user interfaces, integrated safety features, and simple operational controls. This combination allows even operators with basic training to reliably manage starting, stopping, and temperature setting, ensuring both safety and consistent performance.

The true operational advantage of a box furnace isn't just one feature, but the synergy between its simple design, reliable performance, and operational flexibility. This makes it a highly effective and cost-efficient tool for a vast range of thermal processing applications.

The Foundation: Simplicity and Control

The core appeal of a box furnace begins with its user-centric design, which minimizes complexity and reduces the potential for operator error.

Intuitive User Interface

Modern box furnaces feature clean, user-friendly interfaces. Critical functions like starting, stopping, and setting the target temperature are designed to be obvious, significantly reducing the learning curve and training time.

Integrated Safety Systems

Operational safety is paramount. These furnaces typically include essential protections like over-temperature alarms and power leakage protection. These systems safeguard not only the operator but also the equipment and the material being processed.

Inherent Structural Simplicity

At its core, a box furnace is a simple machine: an insulated chamber heated by resistance elements. This straightforward structure results in fewer points of failure, easier troubleshooting, and more predictable maintenance cycles compared to more complex systems.

Performance and Reliability by Design

Beyond simple operation, the furnace's internal design directly contributes to its reliability and the quality of its output.

Achieving High Temperature Uniformity

Consistent results depend on uniform heating. This is achieved through the strategic placement of heating elements and, in some models, the use of circulating fans. A well-designed furnace can typically maintain temperature uniformity within a tight tolerance of ±5°C to ±10°C across the chamber.

Built for Durability and Longevity

The service life of a furnace is determined by its components. The use of high-quality heating elements and insulation materials that are resistant to high temperatures and oxidation ensures long-term stability. This allows for continuous, reliable operation and minimizes costly production downtime.

Modern Focus on Energy Efficiency

Contemporary designs prioritize sustainability and cost reduction. By using high-efficiency insulation materials and optimizing the heating element layout, these furnaces minimize heat loss and improve overall energy utilization, reducing both environmental impact and operational expenses.

Understanding the Trade-offs

While highly versatile, the "universal" nature of the box furnace comes with inherent trade-offs that are important to understand.

Versatility vs. Specialization

The box furnace is a general-purpose tool, making it excellent for labs and varied small-batch production. However, for high-throughput, continuous industrial processes, a specialized furnace (e.g., a tunnel or belt furnace) is often more efficient.

Heating and Cooling Rates

Due to their thermal mass and design for stability, standard box furnaces are not typically engineered for extremely rapid heating or quenching. Processes requiring very fast thermal cycles may need more specialized equipment.

Atmosphere Control

Most standard box furnaces operate with an ambient air atmosphere. While some models can be modified for inert gas environments, they are not inherently designed for the rigorous atmosphere control required in applications like vacuum brazing or advanced sintering.

Making the Right Choice for Your Application

Selecting the right furnace requires matching its operational advantages to your specific goals.

- If your primary focus is research and development: Its operational flexibility, precision, and ease of use make the box furnace an ideal choice for varied experimental needs.

- If your primary focus is consistent small-batch heat treatment: Its excellent temperature uniformity and reliability ensure repeatable, high-quality results with minimal operator oversight.

- If your primary focus is minimizing long-term operational costs: Prioritize modern designs with high-efficiency insulation and durable components to reduce energy consumption and maintenance downtime.

By understanding these core operational principles, you can confidently select and utilize a box furnace as a reliable and effective tool for your thermal processing goals.

Summary Table:

| Operational Advantage | Key Features |

|---|---|

| User-Friendly Interface | Intuitive controls, easy start/stop, minimal training |

| Safety Systems | Over-temperature alarms, power leakage protection |

| Temperature Uniformity | ±5°C to ±10°C tolerance, strategic heating elements |

| Durability & Longevity | High-quality materials, reduced downtime |

| Energy Efficiency | High-efficiency insulation, lower operational costs |

| Versatility | Suitable for R&D and small-batch heat treatment |

Enhance your thermal processing with KINTEK's advanced box furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, boosting efficiency and consistency. Contact us today to discuss how our furnaces can optimize your operations!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation