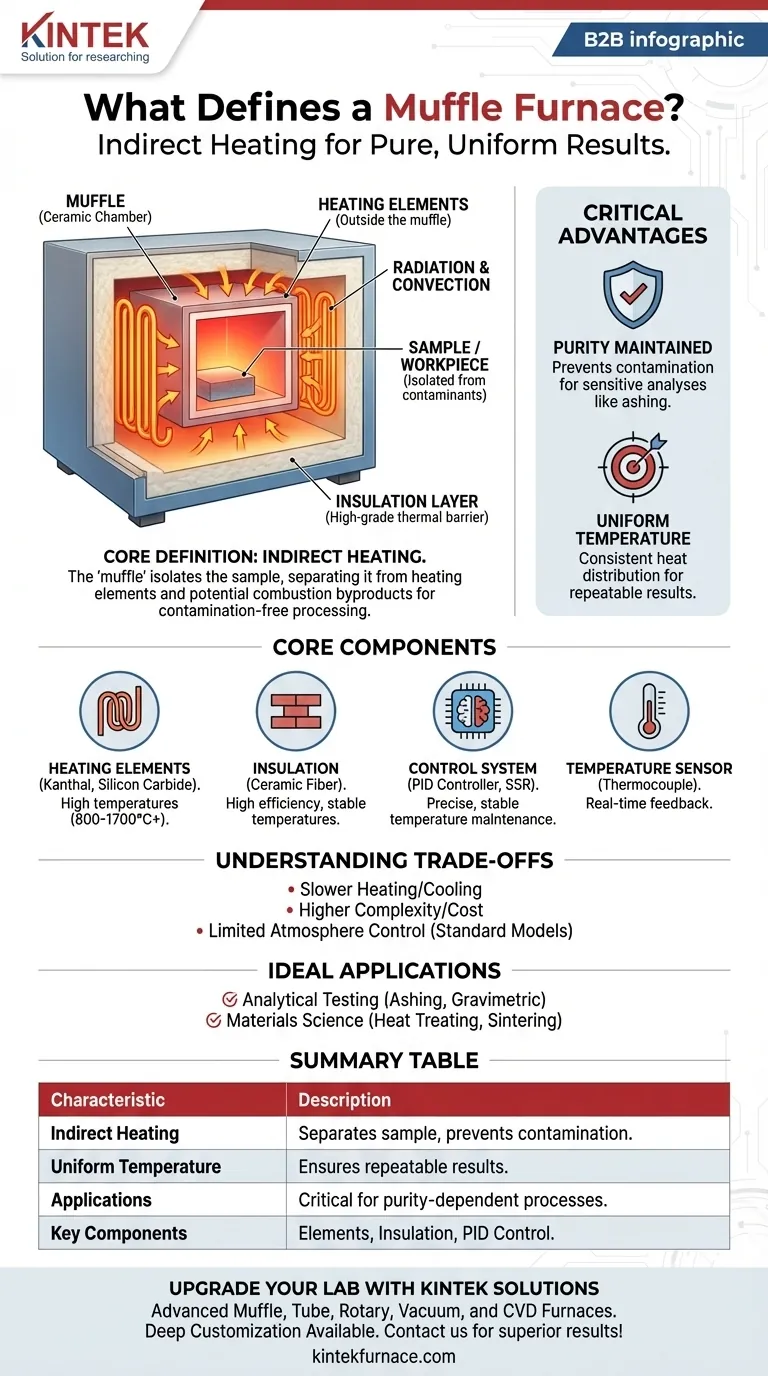

At its core, a muffle furnace is defined by its method of indirect heating. The fundamental characteristic is the use of a "muffle"—an isolated inner chamber—that separates the material being heated from the heating elements and any contaminants, such as the byproducts of combustion in fuel-fired models or off-gassing from the elements themselves. This design ensures the sample's purity is maintained throughout the thermal process.

While many devices can reach high temperatures, a muffle furnace is engineered specifically for applications where sample integrity is paramount. Its defining feature isn't just heat, but clean heat, achieved by physically isolating the workpiece from the heat source.

The Critical Advantage: Why Isolation Matters

The primary purpose of a muffle furnace is to provide uniform, high-temperature heating without introducing external contaminants. This is the deep need it serves, which is critical in many scientific and industrial processes.

The Muffle: A Protective Barrier

The "muffle" is the central component. It is a separate chamber, typically made of high-temperature ceramic, that sits inside the furnace's main insulated body.

Your sample or workpiece is placed inside this muffle. The heating elements are positioned outside the muffle, meaning they never make direct contact with the sample or its immediate atmosphere.

How Heat is Transferred

Heat from the elements transfers into the muffle chamber primarily through radiation and convection.

This indirect method, combined with heavy insulation, creates an extremely uniform temperature throughout the chamber. This uniformity is essential for achieving accurate, repeatable, and predictable results in sensitive processes.

Preventing Contamination and Controlling Atmosphere

By separating the heating elements from the sample, the furnace prevents any particles or gases from the elements from contaminating the material.

This is indispensable for analytical procedures like ashing, where the goal is to burn off all organic matter to measure the inorganic residue. Any contamination would render the results invalid. It also allows for heat treatment of metals without surface oxidation, as the atmosphere inside the muffle can often be controlled.

Core Components of a Modern Furnace

Several key components work together to enable the muffle furnace's precise and clean operation.

The Heating Elements

These are made from high-resistance materials like Kanthal (iron-chromium-aluminum alloy), nichrome, or silicon carbide, capable of reaching temperatures from 800°C to over 1700°C.

The Insulation Layer

To achieve high thermal efficiency and maintain stable temperatures, muffle furnaces use high-grade insulation, such as dense ceramic fiber or glass wool blankets. This minimizes heat loss and keeps the outer casing safe to touch.

The Control System

Modern furnaces rely on sophisticated digital controllers. A PID (Proportional-Integral-Derivative) controller is the standard, constantly adjusting power to the heating elements to precisely maintain the set temperature without overshooting. These are often paired with Solid-State Relays (SSRs) for reliable and quiet power switching.

Temperature Sensors

An accurate temperature sensor, such as a thermocouple, is placed inside the furnace chamber to provide real-time feedback to the controller, ensuring the process temperature matches the user's setpoint.

Understanding the Trade-offs

While highly effective, the muffle furnace design comes with inherent trade-offs.

Heating and Cooling Rates

Because heat is transferred indirectly, muffle furnaces can have slower heating rates compared to direct-fire or induction furnaces. The heavy insulation required for temperature stability also means they can retain heat and cool down slowly.

Cost and Complexity

The dual-chamber design, advanced PID control systems, and high-quality insulation materials make muffle furnaces more complex and generally more expensive than a simple high-temperature oven or a direct-heat furnace.

Atmospheric Limitations

While excellent at preventing contamination from the furnace itself, a standard muffle furnace does not create a vacuum. For processes requiring a specific inert gas atmosphere (like argon) or a vacuum, a specialized model with gas ports and a sealed muffle is required.

Making the Right Choice for Your Goal

Understanding the core principle of isolation helps you determine if a muffle furnace is the correct tool for your task.

- If your primary focus is analytical testing (ashing, gravimetric analysis): A muffle furnace is essential. Its ability to prevent contamination is non-negotiable for accurate results.

- If your primary focus is materials science (heat treating, annealing, sintering): The uniform temperature and ability to protect the material surface from oxidation make it a superior choice.

- If your primary focus is simply high-temperature heating without purity concerns: A less complex and more cost-effective direct-heat furnace may be a better fit.

Ultimately, choosing a muffle furnace is a decision to prioritize process purity and temperature uniformity above all else.

Summary Table:

| Characteristic | Description |

|---|---|

| Indirect Heating | Uses a muffle chamber to separate sample from heating elements, preventing contamination. |

| Uniform Temperature | Achieves even heat distribution via radiation and convection for repeatable results. |

| Applications | Ideal for ashing, heat treatment, annealing, and sintering where purity is critical. |

| Key Components | Includes heating elements (e.g., Kanthal), insulation, PID controllers, and thermocouples. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for pure, uniform heating. Contact us today to discuss how we can enhance your processes and deliver superior results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating