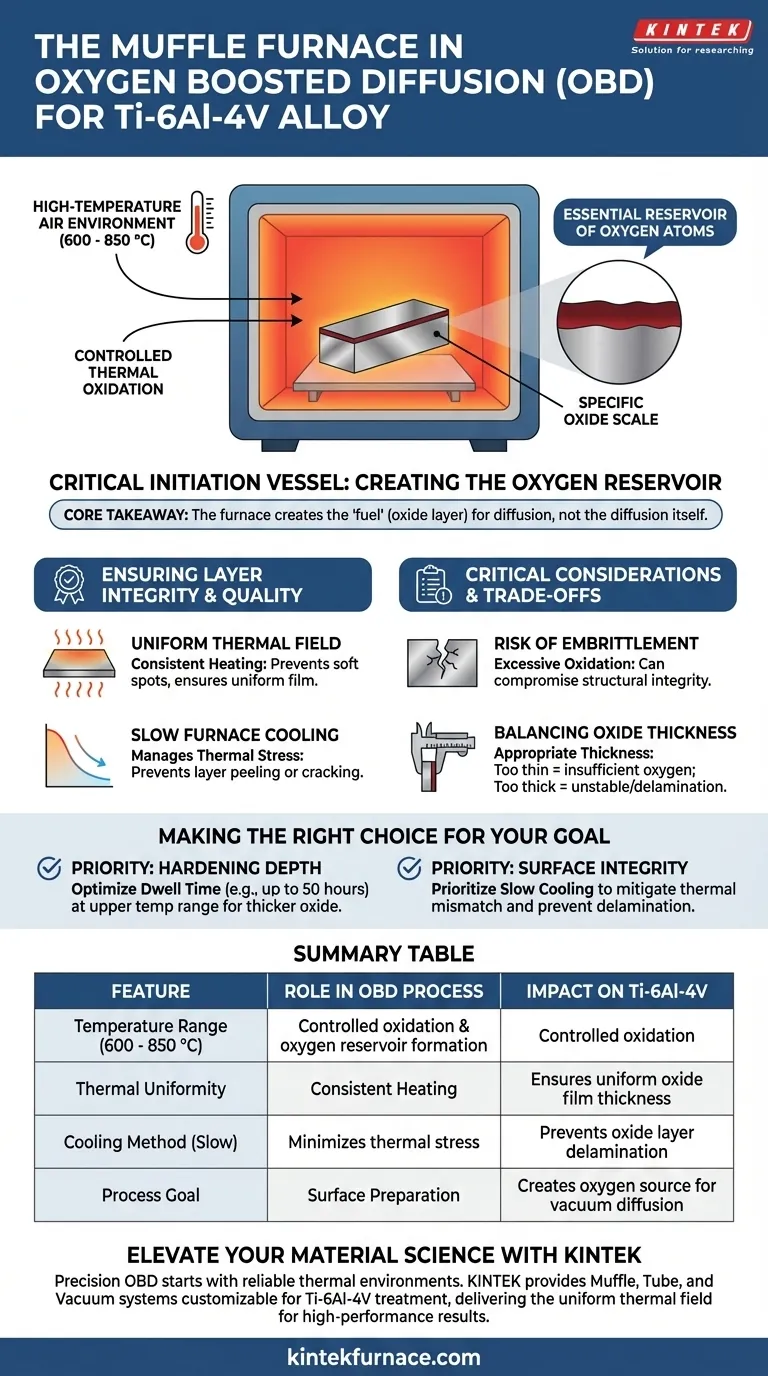

The muffle furnace serves as the critical initiation vessel for the Oxygen Boosted Diffusion (OBD) process. In the specific context of Ti-6Al-4V alloy treatment, its primary role is to subject the material to a high-temperature air environment, typically between 600 and 850 °C. This thermal treatment deliberately provokes oxidation, creating a specific oxide scale on the surface that acts as the essential reservoir of oxygen atoms required for subsequent hardening.

Core Takeaway The muffle furnace does not perform the diffusion itself; rather, it creates the "fuel" for the process. By forming a well-adhered, pre-calculated oxide layer, it establishes the necessary chemical foundation that allows surface hardening to occur during the later vacuum diffusion stage.

The Primary Function: Creating the Oxygen Reservoir

Controlled Thermal Oxidation

The standard challenge with titanium alloys is their high reactivity to oxygen, which is usually avoided. However, the OBD process leverages this trait.

The muffle furnace provides a high-temperature air oxidation environment. By heating the Ti-6Al-4V specimens to the 600–850 °C range, the furnace facilitates a controlled reaction between the alloy surface and the atmospheric oxygen.

Establishing the Diffusion Source

The outcome of this heating cycle is a well-adhered oxide layer of a specific thickness.

This layer is not merely a byproduct; it is the functional goal of this stage. It serves as the source of oxygen atoms. Without this oxide scale properly formed in the muffle furnace, there would be no oxygen available to diffuse into the matrix during the subsequent steps.

Ensuring Layer Integrity and Quality

Uniform Thermal Environment

Creating an oxide layer is simple; creating a useful one requires precision.

A high-quality laboratory muffle furnace ensures a uniform thermal field. This stability is required to ensure the oxide film is consistent across the entire geometry of the part, preventing soft spots or irregular hardening later.

Managing Thermal Stress via Cooling

The transition from high heat to room temperature is a critical vulnerability for the oxide layer.

To prevent the protective layer from peeling or cracking, a slow furnace cooling method is employed. This gradual reduction in temperature releases thermal stress between the brittle oxide film and the metal substrate, ensuring the layer remains intact for the next processing stage.

Critical Considerations and Trade-offs

The Risk of Embrittlement

While the muffle furnace is designed to encourage oxidation, there is a fine line between a functional oxide layer and material damage.

Titanium alloys are highly active. If the temperature is uncontrolled or the dwell time is excessive, the material can absorb too much oxygen too quickly. This can lead to material embrittlement before the diffusion process even begins, compromising the structural integrity of the alloy.

Balancing Oxide Thickness

The muffle furnace parameters must be tuned to produce an oxide layer of appropriate thickness.

If the layer is too thin, there will be insufficient oxygen available for deep diffusion hardening. If the layer is too thick or chemically unstable, it may detach from the substrate, rendering the subsequent vacuum diffusion step ineffective.

Making the Right Choice for Your Goal

To maximize the effectiveness of the OBD process for Ti-6Al-4V, consider these operational priorities:

- If your primary focus is Hardening Depth: Ensure your muffle furnace creates a sufficiently thick oxide reservoir by optimizing the dwell time (e.g., up to 50 hours) at the upper end of the temperature range.

- If your primary focus is Surface Integrity: Prioritize the cooling phase; utilize slow furnace cooling to mitigate thermal mismatch and prevent the oxide scale from delaminating.

Ultimately, the muffle furnace transforms the alloy's surface into a chemically active resource, laying the indispensable foundation for the entire Oxygen Boosted Diffusion system.

Summary Table:

| Feature | Role in OBD Process | Impact on Ti-6Al-4V |

|---|---|---|

| Temperature Range | 600 - 850 °C | Controlled oxidation and oxygen reservoir formation |

| Thermal Uniformity | Consistent Heating | Ensures uniform oxide film thickness across complex geometries |

| Cooling Method | Slow Furnace Cooling | Minimizes thermal stress and prevents oxide layer delamination |

| Process Goal | Surface Preparation | Creates the oxygen source for subsequent vacuum diffusion stage |

Elevate Your Material Science with KINTEK

Precision in the Oxygen Boosted Diffusion (OBD) process starts with a reliable thermal environment. KINTEK provides industry-leading Muffle, Tube, and Vacuum systems designed to give you absolute control over oxidation and diffusion parameters.

Backed by expert R&D and manufacturing, our laboratory high-temp furnaces are fully customizable to meet the rigorous demands of Ti-6Al-4V alloy treatment. Whether you need to optimize hardening depth or ensure surface integrity, our equipment delivers the uniform thermal field required for high-performance results.

Ready to upgrade your lab's capabilities? Contact KINTEK today to discuss your unique needs with our technical specialists.

Visual Guide

References

- Yujie Xu, Jianming Gong. Effect of Temperature, Vacuum Condition and Surface Roughness on Oxygen Boost Diffusion of Ti–6Al–4V Alloy. DOI: 10.3390/coatings14030314

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What certifications does the muffle furnace have? Ensure Compliance and Safety for Your Lab

- What is a hydrogen muffle furnace and how does it work? Precision Heating with Hydrogen for Oxide-Free Results

- What is the purpose of the port at the rear of the chamber in a muffle furnace? Unlock Precision Control for Your Lab

- Why is a Muffle Furnace required for lithium recovery? Boost Yield with Precise Sulfuric Acid Roasting

- What role does a high-temperature muffle furnace play in the preparation of acid-activated clay? Key Thermal Mechanisms

- What is the specific role of a box muffle furnace in the austenitizing of Vanadis 60? Achieve Precise Hardening Control

- What should be done if the silicon carbon rod in the muffle furnace ages? Restore Performance with Expert Tips

- How does a high-temperature muffle furnace facilitate the dual heat treatment of Ti0.96Nb0.04O2? Master Conductivity