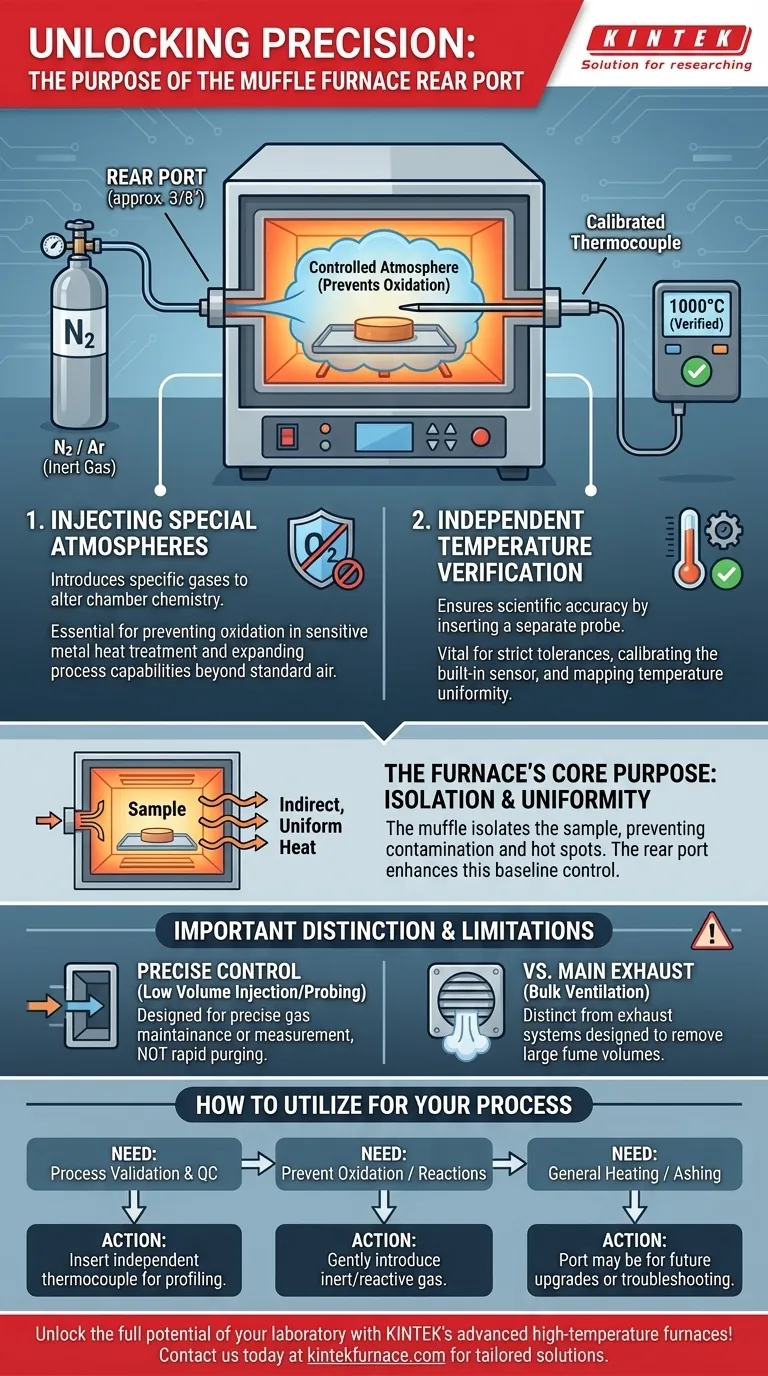

At its core, the port at the rear of a muffle furnace chamber serves two primary functions. It allows an operator to inject a specialized atmosphere into the chamber or to insert an independent probe for monitoring and verifying the internal temperature.

The rear port is a critical feature that transforms a muffle furnace from a simple high-temperature oven into a precise scientific instrument. It provides a gateway for actively controlling and verifying the internal environment, which is essential for advanced material processing and repeatable experiments.

The Furnace's Purpose: A Controlled Environment

A muffle furnace is fundamentally designed to create an isolated, high-temperature environment. Understanding this core purpose reveals why a small access port is so valuable.

The Role of the Muffle Chamber

The "muffle" is the insulated ceramic interior of the furnace. Its key job is to isolate the sample from the heating elements and any combustion by-products.

This indirect heating method ensures the sample receives uniform heat through radiation and convection, preventing contamination and hot spots that would occur from direct flame contact.

The Principle of Isolation

By sealing the sample within the muffle, the furnace creates a baseline controlled environment. This is crucial for processes like ashing (burning off organic material) or sintering (fusing powders together) where purity and consistency are paramount.

The Port's Role in Enhancing Control

While the muffle provides passive control, the rear port enables active, precise control and verification of the chamber's conditions.

Injecting Special Atmospheres

Many advanced processes cannot be performed in standard air. The port allows you to introduce specific gases to alter the chamber's chemistry.

For example, injecting an inert gas like nitrogen or argon prevents oxidation when heat-treating sensitive metals. This expands the furnace's capability far beyond simple heating.

Independent Temperature Verification

A furnace's built-in temperature controller is a guide, but for scientific accuracy, verification is essential. The port allows you to insert a separate, calibrated thermocouple.

This practice is vital for applications requiring strict temperature tolerances, for calibrating the furnace's own sensor, or for ensuring temperature uniformity throughout the chamber. It builds confidence and ensures the process is running exactly as specified.

Understanding the Practical Applications

The port's functions are not just theoretical; they are essential for specific, common applications that demand a higher level of process control.

Distinguishing from an Exhaust System

It is important to note that this small port is distinct from a furnace's main exhaust or vent system. An exhaust is designed to remove large volumes of fumes, such as the toxic gases released during the ashing of certain materials.

The rear port, being much smaller (typically around 3/8"), is designed for the precise, low-volume injection of gases or the insertion of a slender monitoring probe. It is a tool for control, not bulk ventilation.

Limitations to Consider

The port's small diameter means it is not suitable for rapidly purging the chamber or for processes that require a high flow rate of gas. Its purpose is to maintain a specific atmosphere or allow for precise measurement, not to fundamentally alter the pressure or flow dynamics of the entire system.

How to Utilize the Port for Your Process

Leveraging the rear port effectively depends entirely on the precision your work demands.

- If your primary focus is process validation and quality control: Use the port to insert an independent thermocouple to verify and map the chamber's temperature profile.

- If your primary focus is preventing oxidation or unwanted reactions: Use the port to gently introduce an inert or specific reactive gas to control the chamber's atmosphere.

- If your primary focus is general heating or simple ashing in air: The port may not be necessary for your immediate task, but it remains a valuable feature for troubleshooting or future process upgrades.

Ultimately, this port is the key to unlocking the full potential of your muffle furnace for precise and repeatable scientific work.

Summary Table:

| Function | Purpose | Common Uses |

|---|---|---|

| Atmosphere Injection | Introduce inert or reactive gases to control chamber chemistry | Prevent oxidation in metal heat treatment, enable specific reactions |

| Temperature Verification | Insert independent thermocouple for accurate monitoring | Calibrate furnace sensors, ensure temperature uniformity in sintering and ashing |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing accuracy and repeatability. Contact us today to discuss how our expertise can elevate your processes and deliver superior results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity