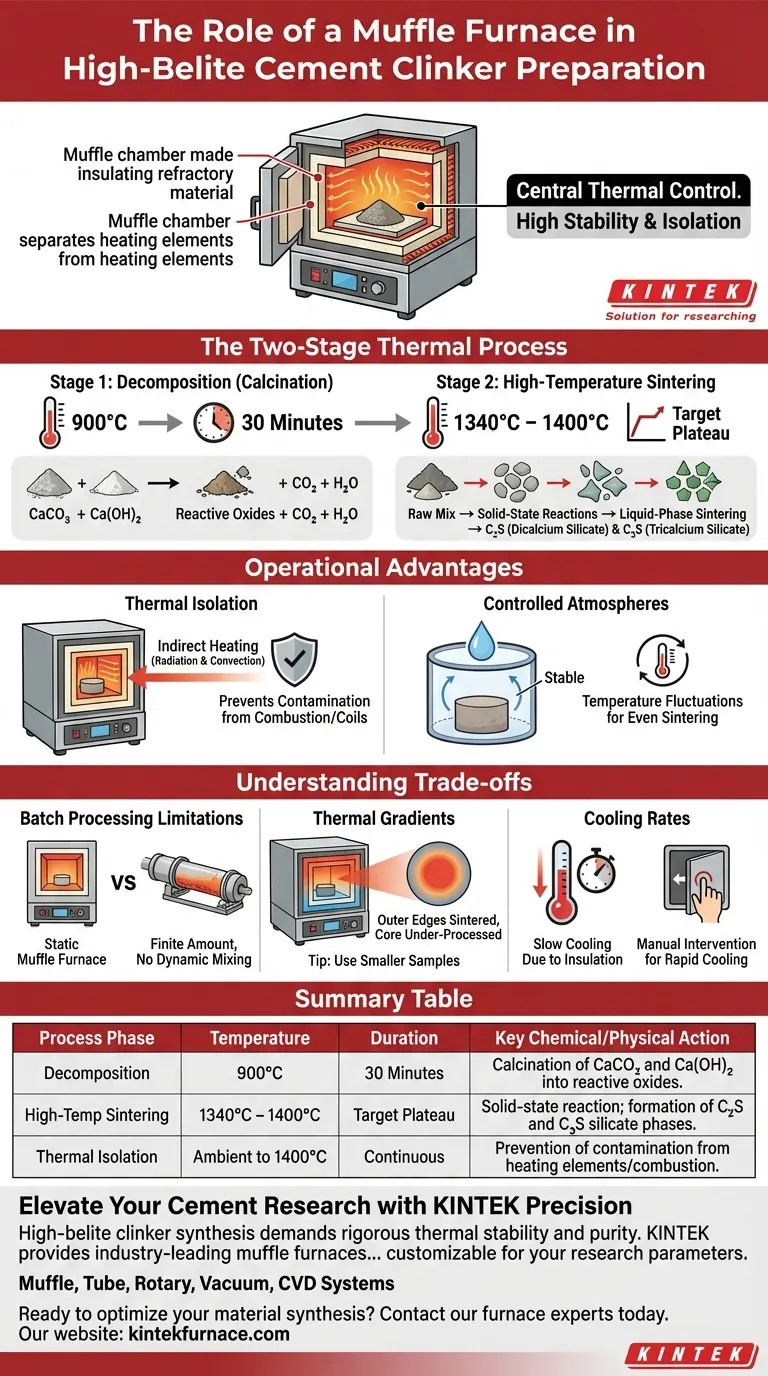

A Muffle Furnace functions as the central thermal control unit during the preparation of high-belite cement clinker. It provides a highly stable, isolated environment to execute a two-stage heating process: first maintaining 900°C to decompose raw materials, and subsequently reaching 1340°C to 1400°C to drive the sintering necessary for mineral formation.

The Muffle Furnace is critical because it isolates the material from fuel combustion byproducts while delivering the precise thermodynamic conditions required to transform raw calcium mixtures into structural silicate phases like $C_2S$ and $C_3S$.

The Two-Stage Thermal Process

Stage 1: Decomposition of Raw Materials

The first role of the muffle furnace is to facilitate the complete calcination of the raw mix.

The furnace holds the material at a steady temperature of 900°C for approximately 30 minutes.

During this phase, calcium carbonate ($CaCO_3$) and calcium hydroxide ($Ca(OH)_2$) chemically decompose, releasing carbon dioxide and water to leave behind reactive calcium oxides.

Stage 2: High-Temperature Sintering

Once decomposition is complete, the furnace raises the temperature to a target range of 1340°C to 1400°C.

This high-temperature plateau provides the necessary thermodynamic energy for solid-state reactions and liquid-phase sintering.

It is during this stage that the distinct mineral phases of the clinker—specifically dicalcium silicate ($C_2S$) and tricalcium silicate ($C_3S$)—are crystallized and stabilized.

The Operational Advantage

Thermal Isolation

A defining feature of the muffle furnace is the separation of the heating element from the chamber using an insulating "muffle," often made of glass wool or refractory material.

This ensures that the cement clinker is heated by radiation and convection rather than direct contact with a flame or heating element.

This isolation prevents contamination from heating coils or fuel sources, ensuring the chemical purity of the final clinker.

Controlled Atmospheres

While high-belite clinker is typically sintered in air, the muffle design stabilizes the atmosphere around the sample.

This stability prevents temperature fluctuations that could lead to incomplete sintering or uneven mineral distribution within the clinker nodule.

Understanding the Trade-offs

Batch Processing Limitations

Most muffle furnaces used for this application are designed for batch processing, meaning they handle a finite amount of material at a time.

While excellent for research or small-scale synthesis, they do not replicate the continuous movement and mixing found in industrial rotary kilns.

Thermal Gradients

Despite the insulation, static muffle furnaces can develop thermal gradients (hot or cold spots) within the chamber.

If the sample is too large or placed incorrectly, the outer edges may sinter perfectly at 1400°C while the core remains under-processed.

Cooling Rates

Muffle furnaces generally cool down slowly due to their heavy insulation.

High-belite clinker often requires specific cooling regimes to stabilize the desired polymorphs of $C_2S$; a standard muffle furnace may require manual intervention (such as opening the door) to achieve the necessary rapid cooling rates.

Making the Right Choice for Your Goal

The muffle furnace is the standard for precision and purity in clinker synthesis. To ensure success:

- If your primary focus is Phase Purity: Ensure the furnace can hold the 1340°C–1400°C range within a tight tolerance ($\pm$5°C) to maximize the formation of $C_3S$.

- If your primary focus is Material Homogeneity: Use smaller sample sizes to negate the effects of thermal gradients inside the static chamber.

- If your primary focus is Process Simulation: Recognize that static sintering in a muffle furnace may yield slightly different microstructures than the dynamic rolling action of an industrial kiln.

Success in preparing high-belite clinker relies not just on reaching high temperatures, but on the precise timing and stability of the thermal ramp that only a quality furnace can provide.

Summary Table:

| Process Phase | Temperature | Duration | Key Chemical/Physical Action |

|---|---|---|---|

| Decomposition | 900°C | 30 Minutes | Calcination of $CaCO_3$ and $Ca(OH)_2$ into reactive oxides. |

| High-Temp Sintering | 1340°C – 1400°C | Target Plateau | Solid-state reaction; formation of $C_2S$ and $C_3S$ silicate phases. |

| Thermal Isolation | Ambient to 1400°C | Continuous | Prevention of contamination from heating elements/combustion. |

Elevate Your Cement Research with KINTEK Precision

High-belite clinker synthesis demands rigorous thermal stability and purity. KINTEK provides industry-leading muffle furnaces designed to handle the critical 1400°C threshold with the precision your mineralogy requires.

Backed by expert R&D and world-class manufacturing, we offer a full suite of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific research parameters. Whether you need to eliminate thermal gradients or simulate complex industrial cooling regimes, KINTEK has the solution.

Ready to optimize your material synthesis?

Contact our furnace experts today to find the perfect high-temperature system for your laboratory.

Visual Guide

References

- Jiapeng Duan, Wenbo Xin. Utilization of Low-Grade Limestone and Solid Waste for the Preparation of High-Belite Portland Cement. DOI: 10.3390/ma18112641

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a high-temperature calcination furnace play in HZSM-5 zeolite? Powering Catalyst Activation

- How does an industrial box resistance furnace facilitate the calcination of Mn-Zn ferrite? Boost Process Stability

- How are muffle furnaces used in jewelry making? Achieve Precision in Metal Clay and Annealing

- What safety features do muffle furnaces have? Essential Protection for High-Temperature Operations

- What are the temperature capabilities of muffle furnaces? Find Your Perfect High-Temp Solution

- What are some additional options available for Box Furnaces? Enhance Your Thermal Processing Efficiency

- What are common high-temperature applications of muffle furnaces in laboratories? Unlock Precision in Material Testing and Synthesis

- What is the role of a muffle furnace in the final formation of a composite photoanode? Master Heterojunction Synthesis