Beyond a simple list, the additional options for a box furnace fall into distinct categories designed to enhance material handling, control the processing atmosphere, automate and monitor operations, and ensure long-term reliability. These upgrades transform a general-purpose furnace into a specialized tool tailored for specific industrial processes like hardening, annealing, or tempering.

A standard box furnace provides heat, but optional systems are what deliver true process control. The decision to add options is about moving from basic heating to achieving highly repeatable, efficient, and documented thermal processing results.

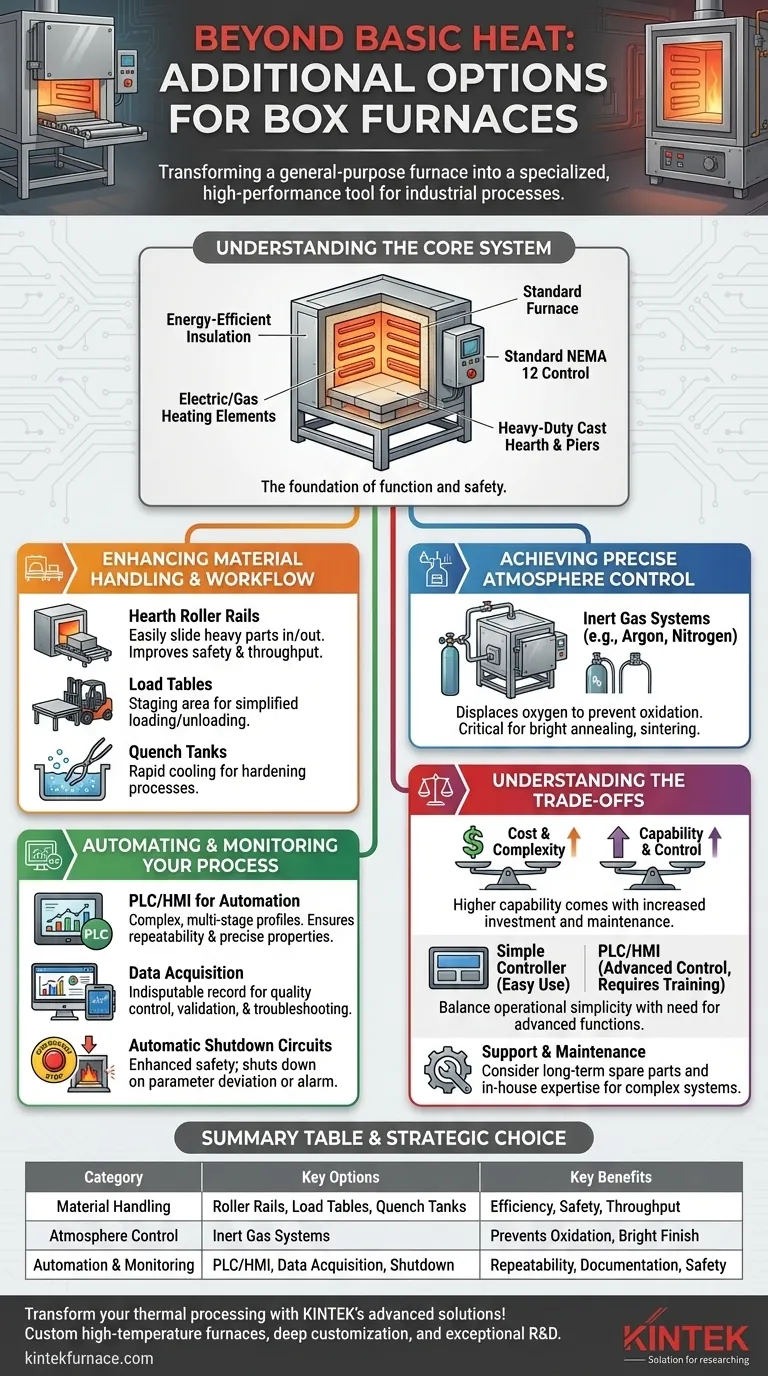

Understanding the Core System

Before exploring options, it's essential to recognize the standard features that form the foundation of a modern box furnace. These are not optional; they are integral to its basic function and safety.

Standard Design and Control

A typical box furnace is built with energy-efficient, high-density insulation to retain heat. It uses electric heating elements or proportional gas heat, controlled by a standard NEMA 12 control panel with a single-point controller and essential safety features like an E-stop.

Built-in Durability

Features like heavy-duty cast hearths and piers are standard because they are critical for supporting loads at high temperatures and ensuring the furnace has a long operational life.

Enhancing Material Handling and Workflow

These options are focused on improving the efficiency of moving materials into and out of the furnace, reducing manual labor and integrating the furnace into a larger production line.

Hearth Roller Rails

For heavy or cumbersome loads, hearth roller rails provide a mechanical advantage, allowing operators to easily slide parts into and out of the hot zone. This is crucial for both safety and throughput.

Load Tables

A load table is a platform positioned in front of the furnace, often at the same height as the hearth. It acts as a staging area, simplifying the loading and unloading process, especially when coordinated with a forklift or overhead crane.

Quench Tanks

For hardening processes, a quench tank is essential. Placed near the furnace, it allows for the rapid cooling of parts in a controlled medium (like water, oil, or polymer) immediately after they are removed from the heat.

Achieving Precise Atmosphere Control

Many advanced materials and processes cannot be heated in ambient air due to the risk of oxidation and scaling. Atmosphere control systems address this directly.

Inert Gas Systems

A gas-sealed option with an inert gas system (using gases like argon or nitrogen) displaces oxygen from the heating chamber. This is critical for processes like bright annealing or sintering, where a clean, unoxidized surface finish is required.

Automating and Monitoring Your Process

These systems are about taking human variability out of the equation to ensure every cycle is identical, documented, and safe.

PLC/HMI for Process Automation

Upgrading from a standard controller to a Programmable Logic Controller (PLC) with a Human-Machine Interface (HMI) allows for complex, multi-stage heating and cooling profiles. This automation is key for achieving precise metallurgical properties and ensuring process repeatability.

Data Acquisition

A data acquisition system automatically logs critical process variables like temperature and time. This provides an indisputable record for quality control, process validation, and troubleshooting, which is often a requirement in aerospace and medical manufacturing.

Automatic Shutdown Circuits

These are enhanced safety systems that can be programmed to shut down the furnace if it deviates from set parameters or if an external alarm is triggered. This protects the equipment, the product, and personnel during unattended operation.

Understanding the Trade-offs

Adding options increases capability, but it also introduces complexity and cost. A clear-eyed assessment of the trade-offs is necessary.

Cost vs. Capability

An inert gas system provides superior results for sensitive parts but increases the initial investment and ongoing operational costs (gas consumption). You must weigh the cost against the value of preventing oxidation.

Simplicity vs. Control

A standard digital controller is simple to operate and maintain. A PLC/HMI offers unparalleled control and data logging but requires more sophisticated operator training and technical support for programming and troubleshooting.

Support and Maintenance

More systems mean more potential points of failure. While options like field installation and commissioning are available, you must also consider the long-term availability of spare parts and the in-house expertise needed to maintain these advanced systems.

Making the Right Choice for Your Application

Your process requirements should dictate your choice of options.

- If your primary focus is high throughput and workflow efficiency: Prioritize material handling options like hearth roller rails and load tables.

- If your primary focus is material integrity and preventing oxidation: The inert gas atmosphere system is your most critical option.

- If your primary focus is process repeatability and quality documentation: Invest in a PLC/HMI and a data acquisition system.

- If your primary focus is running complex, multi-stage heat cycles: A PLC/HMI is not an option but a necessity.

Ultimately, selecting the right options is a strategic decision that aligns the furnace's capabilities directly with your specific manufacturing goals.

Summary Table:

| Category | Key Options | Key Benefits |

|---|---|---|

| Material Handling | Hearth Roller Rails, Load Tables, Quench Tanks | Improves workflow efficiency, safety, and throughput |

| Atmosphere Control | Inert Gas Systems | Prevents oxidation, ideal for bright annealing and sintering |

| Automation & Monitoring | PLC/HMI, Data Acquisition, Automatic Shutdown Circuits | Ensures repeatability, documentation, and enhanced safety |

| Trade-offs | Cost vs. Capability, Simplicity vs. Control | Balances investment with operational needs and maintenance |

Transform your thermal processing with KINTEK's advanced box furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with custom high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental requirements. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety