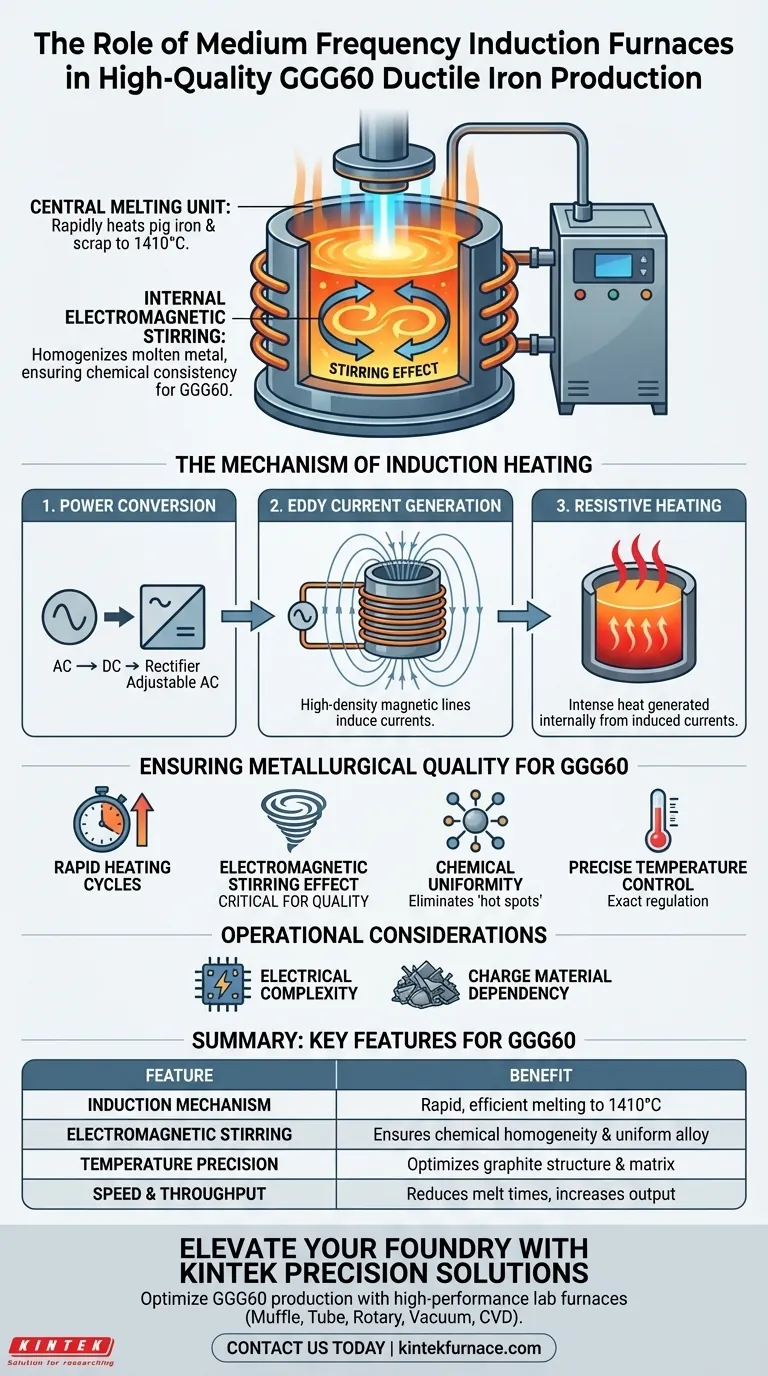

A medium frequency induction furnace serves as the central melting unit for producing high-quality ductile iron, utilizing electromagnetic fields to rapidly heat raw materials like pig iron and scrap steel to temperatures as high as 1410°C. Beyond simple melting, its specific role is to generate an internal "stirring effect" that homogenizes the molten metal, ensuring the chemical consistency required for advanced alloys like GGG60.

While rapid melting is a key feature, the true value of the medium frequency induction furnace lies in its ability to create a chemically uniform matrix through electromagnetic stirring. This uniformity is the prerequisite for achieving the specific mechanical properties and graphite structure demanded by GGG60 ductile iron.

The Mechanism of Induction Heating

Converting Power to Heat

The furnace operates by manipulating electrical current to generate heat directly within the metal. It begins by converting standard three-phase power frequency alternating current (AC) into direct current (DC).

Generating Eddy Currents

This DC is then transformed back into an adjustable AC supply that powers an induction coil. As current flows through this coil, it generates high-density magnetic lines of force that intersect the metal charge.

Resistive Heating

These magnetic fields induce significant eddy currents within the metal itself. As these currents force free electrons to flow through the metal's resistive body, intense heat is generated from the inside out, rather than being applied externally.

Ensuring Metallurgical Quality for GGG60

Rapid Heating Cycles

Efficiency is a primary advantage. The induction process allows for extremely high heating speeds, quickly bringing the charge to the target temperature of 1410°C.

The Electromagnetic Stirring Effect

This is the most critical factor for quality. The induction current naturally produces a stirring effect within the molten bath.

Chemical Uniformity

This stirring action ensures that all alloy elements and chemical components are distributed evenly throughout the melt. For GGG60, which requires a precise matrix structure, this eliminates "hot spots" or areas of poor alloy concentration.

Precise Temperature Control

The furnace allows for exact regulation of the power input. This enables operators to maintain the specific thermal parameters required to optimize the microstructure of the ductile iron before casting.

Operational Considerations and Trade-offs

Electrical Complexity

Unlike simple combustion furnaces, this system relies on complex power electronics to manage the AC-DC-AC conversion. This requires stable power supplies and specialized maintenance of the capacitor and coil systems.

Charge Material Dependency

The efficiency of the heating is directly related to the electromagnetic properties of the charge material. The process relies on the material's resistance to generate heat, meaning the composition of the scrap steel and pig iron must be carefully managed.

Making the Right Choice for Your Goal

To maximize the potential of a medium frequency induction furnace in your foundry:

- If your primary focus is Production Speed: Leverage the high-density magnetic fields to minimize melt times and increase throughput.

- If your primary focus is Material Consistency (GGG60): Prioritize the electromagnetic stirring phase to guarantee a uniform chemical matrix before pouring.

By mastering the balance between rapid heating and electromagnetic stirring, you ensure that every batch of GGG60 meets the rigorous standards required for high-performance applications.

Summary Table:

| Feature | Benefit for GGG60 Production |

|---|---|

| Induction Mechanism | Generates heat internally for rapid, efficient melting up to 1410°C |

| Electromagnetic Stirring | Ensures chemical homogeneity and uniform distribution of alloy elements |

| Temperature Precision | Allows exact regulation to optimize graphite structure and matrix |

| Speed & Throughput | High-density magnetic fields reduce melt times and increase output |

Elevate Your Foundry with KINTEK Precision Solutions

Are you looking to optimize your GGG60 ductile iron production? Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside customizable lab high-temp furnaces tailored to your unique metallurgical needs.

Our advanced heating technology ensures the chemical consistency and precise temperature control your advanced alloys demand. Contact us today to discuss how our customizable furnace solutions can enhance your lab's efficiency and material quality!

Visual Guide

References

- İsmail Aykut Karamanlı, Okan Ünal. Study of the Wear Resistance Plasma Nitrided GGG60 by Optimization of Surface Treatment Conditions Using Response Surface Methodology. DOI: 10.1007/s40962-024-01310-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does the vacuum arc melting process work? Achieve High-Purity Metals for Demanding Applications

- What is vacuum induction melting (VIM) of superalloys? Achieve Superior Purity for Extreme Environments

- What is the function of a Vacuum Induction Melting Furnace? Essential Precision for Steel Research

- How does the vacuum chamber in a vacuum casting furnace function? Unlock Purity and Performance in Metal Casting

- What are the advantages of using an induction melting furnace? Faster Melting, Lower Costs, Higher Purity

- What types of metals and alloys are typically melted in induction-heated vacuum furnaces? Essential for High-Performance Materials

- What role does a Vacuum Induction Melting Furnace play in the production of weather-resistant steel? Precision Engineering

- What is the role of a Vacuum Induction Melting (VIM) furnace in Invar 36 production? Ensure Purity & Precision