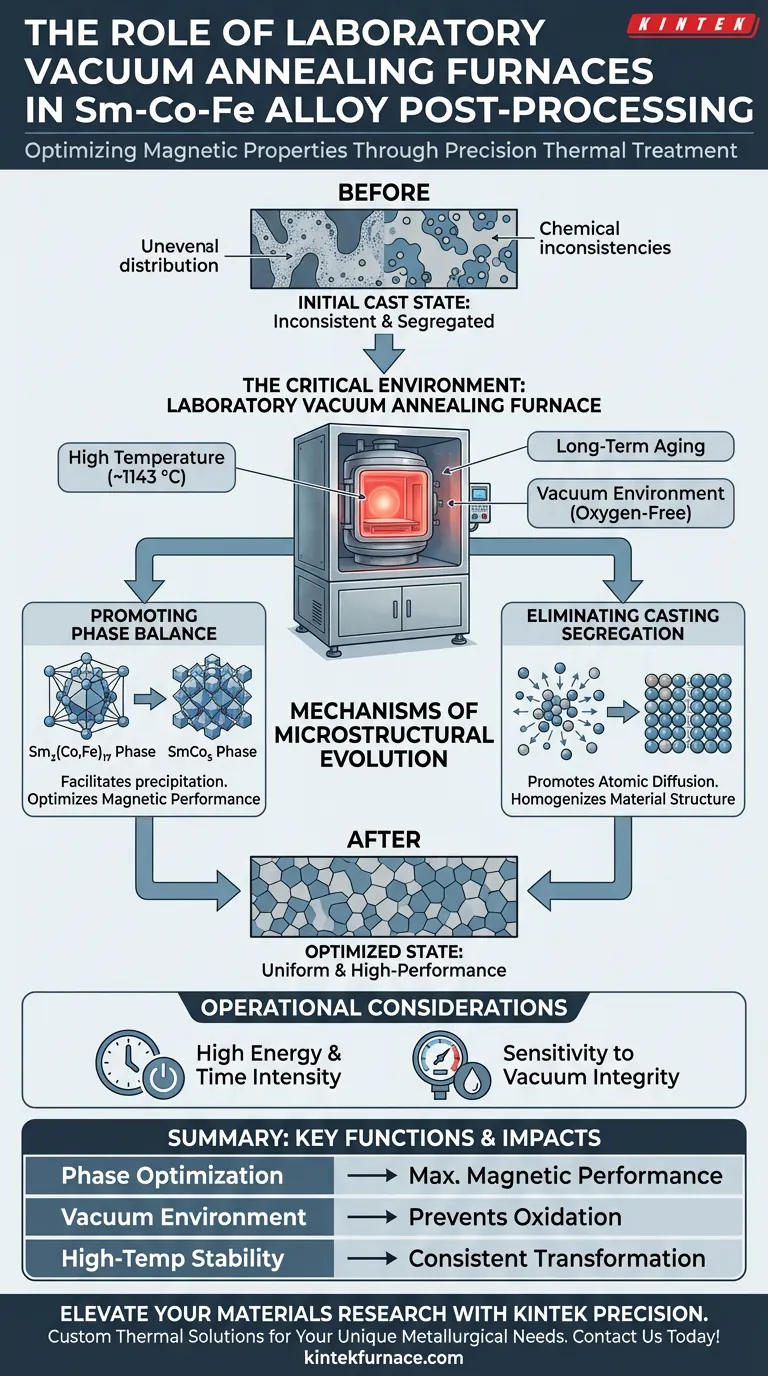

A laboratory vacuum annealing furnace serves as the critical environment for the structural optimization of Sm-Co-Fe alloys. It provides a precise, high-temperature setting—often around 1143 °C—to conduct long-term aging treatments. This process is essential for driving solid-state phase transformations that define the material's final magnetic properties.

The core function of this equipment is to drive the alloy toward thermodynamic equilibrium, facilitating the balanced precipitation of magnetic phases while eliminating the chemical inconsistencies inherent in the casting process.

Mechanisms of Microstructural Evolution

The deep need for using this specific furnace lies in its ability to manipulate the alloy's internal structure at the atomic level.

Promoting Phase Balance

The primary goal of the annealing process is to optimize the distribution of magnetic phases. Specifically, the furnace facilitates the growth and precipitation of $Sm_2(Co,Fe)_{17}$ and $SmCo_5$ phases.

Achieving the correct ratio and distribution of these phases is vital. It directly dictates the magnetic performance of the final material.

Eliminating Casting Segregation

When alloys are first cast, they often suffer from segregation, where elements are unevenly distributed.

The vacuum annealing furnace utilizes high temperatures to promote atomic diffusion. This eliminates these inconsistencies, homogenizing the material and ensuring a uniform microstructure throughout the alloy.

The Importance of Environmental Control

Beyond temperature, the "vacuum" component of the furnace plays a decisive role in material purity.

Prevention of Oxidation

Sm-Co-Fe alloys contain reactive elements that can degrade rapidly in the presence of oxygen.

By operating in a vacuum, the furnace creates an oxygen-free environment. This protects the surface of the alloy from intense oxidation during the high-temperature treatment, ensuring the material retains its intended chemical composition.

Precision Thermal Regulation

Long-term aging requires absolute thermal stability.

The furnace maintains a constant, uniform thermal field over extended periods. This stability is required to ensure that the solid-state phase transformations occur consistently across the entire sample volume, rather than just at the surface.

Operational Considerations and Trade-offs

While essential for high-performance alloys, vacuum annealing presents specific challenges that must be managed.

High Energy and Time Intensity

The process involves "long-term aging," often requiring temperatures exceeding 1100 °C for extended durations.

This results in significant energy consumption and longer production cycles compared to lower-temperature treatments.

Sensitivity to Vacuum Integrity

The quality of the outcome is entirely dependent on the quality of the vacuum.

Any leakage or failure to remove volatile impurities can lead to surface oxidation or the formation of pores, effectively negating the benefits of the heat treatment.

Making the Right Choice for Your Goal

When incorporating a vacuum annealing furnace into your workflow, consider your specific material objectives.

- If your primary focus is Magnetic Performance: Prioritize precise temperature control to maximize the precipitation of the $Sm_2(Co,Fe)_{17}$ phase.

- If your primary focus is Material Purity: Ensure your system has high-vacuum capabilities to prevent surface oxidation of reactive Samarium (Sm).

The laboratory vacuum annealing furnace is not just a heater; it is a precision instrument for engineering the atomic architecture of high-performance magnetic alloys.

Summary Table:

| Feature | Function in Sm-Co-Fe Processing | Impact on Material |

|---|---|---|

| Phase Optimization | Facilitates $Sm_2(Co,Fe)_{17}$ & $SmCo_5$ precipitation | Maximizes magnetic performance |

| Vacuum Environment | Eliminates oxygen and reactive gases | Prevents surface oxidation and maintains purity |

| High-Temp Stability | Provides uniform thermal fields (up to 1143 °C) | Ensures consistent solid-state transformation |

| Atomic Diffusion | Homogenizes material structure | Eliminates chemical segregation from casting |

Elevate Your Materials Research with KINTEK Precision

Unlock the full magnetic potential of your Sm-Co-Fe alloys with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you require precise aging treatments or complex solid-state phase transformations, our lab high-temp furnaces are fully customizable to meet your unique metallurgical needs.

Ready to optimize your annealing process? Contact us today to speak with a specialist!

Visual Guide

References

- Zhi Hong Zhu, Jiashuo Zhang. Effect of Fe Content on Phase Behavior of Sm–Co–Fe Alloys During Solidification and Aging. DOI: 10.3390/ma18081854

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What is the primary function of a laboratory vacuum drying oven? Essential Electrode Sheet Processing Explained

- What are the overall benefits of using vacuum heat treatment furnaces? Achieve Superior Material Purity and Performance

- What is the core function of a vertical vacuum furnace in recycling waste magnesium alloys? Purify Magnesium via Vacuum Sublimation

- What role does a laboratory vacuum annealing furnace play in ion-implanted ScN thin films? Restore Lattice Integrity

- What is the purpose of utilizing a high vacuum system and vacuum sealing? Ensure Purity in Alloy Synthesis

- How does vacuum sintering improve material properties? Boost Strength, Purity, and Performance

- What is the difference between vacuum hardening and normal hardening? A Guide to Superior Surface Quality

- Why is long-duration temperature stability in a sintering furnace essential for Bi-2223? Master Phase Purity