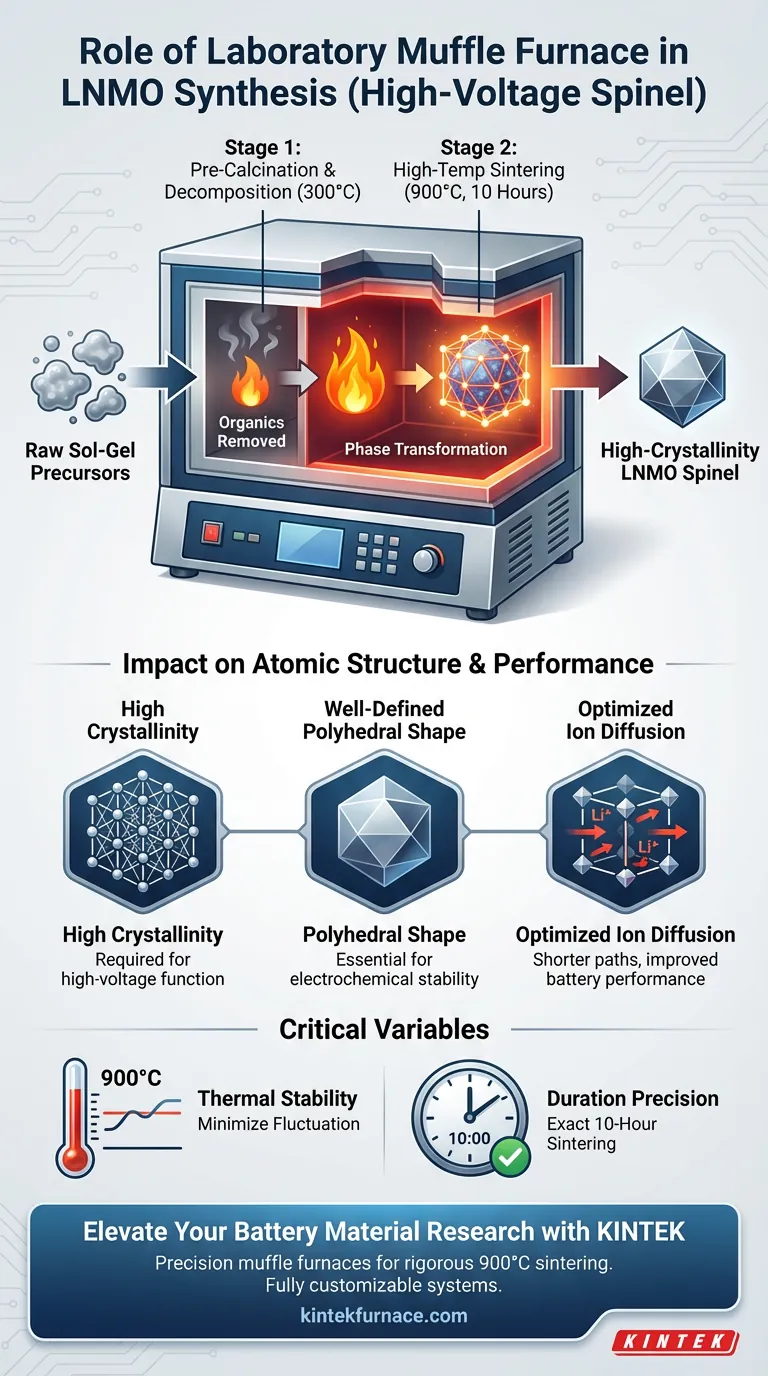

The laboratory muffle furnace acts as the critical vessel for phase transformation in the sol-gel synthesis of high-voltage spinel lithium nickel manganese oxide (LNMO). It executes the necessary two-stage thermal treatment, managing the transition from raw chemical precursors to a highly crystalline, electrochemically active cathode material.

The furnace’s ability to deliver precise thermal management across distinct heating stages is the deciding factor in achieving the well-defined polyhedral crystal structure required for efficient lithium-ion transport.

The Role of Dual-Stage Thermal Treatment

The synthesis of LNMO is not a single-step heating process. The muffle furnace must facilitate two distinct thermal events to ensure the material's quality.

Stage 1: Pre-Calcination and Decomposition

The first function of the furnace is to provide a controlled environment for pre-calcination at 300°C.

At this temperature, the furnace facilitates the initial decomposition of the sol-gel precursors. This step effectively removes organic components and prepares the intermediate material for high-temperature crystallization.

Stage 2: High-Temperature Sintering

Following decomposition, the furnace must ramp up to a stable 900°C environment.

This temperature is maintained for a specific duration of 10 hours. This sustained thermal energy is what drives the final solid-state reaction, converting the intermediate mixture into the final spinel oxide phase.

Impact on Atomic Structure and Performance

The primary value of the muffle furnace lies in its ability to dictate the microscopic architecture of the cathode material.

Achieving High Crystallinity

The precise thermal control at 900°C ensures the LNMO develops high crystallinity.

Without this intense, regulated heat, the material would lack the structural order necessary to function effectively as a high-voltage cathode.

Defining the Polyhedral Shape

Proper sintering results in a well-defined polyhedral crystal structure.

This specific morphology is not merely aesthetic; it is essential for the material's electrochemical stability.

Optimizing Ion Diffusion

The structural clarity achieved in the furnace directly impacts performance by shortening lithium-ion diffusion paths.

Shorter paths mean lithium ions can move more freely, significantly improving the battery's charge and discharge capabilities.

Critical Variables and Requirements

While the muffle furnace is a robust tool, the synthesis relies on adhering to strict parameters. Deviations here can ruin the batch.

Thermal Stability

The furnace must maintain the 900°C setpoint with minimal fluctuation.

Inconsistencies in temperature can lead to incomplete phase formation or lattice defects, similar to how precise control is required in other regeneration processes like that of LFP.

Duration Precision

The 10-hour duration is a critical variable, not a suggestion.

Cutting this time short prevents full crystallization, while extending it unnecessarily may alter the grain size unfavorably.

Making the Right Choice for Your Goal

To maximize the performance of your LNMO cathode material, you must strictly align your furnace protocols with the synthesis requirements.

- If your primary focus is precursor purity: Prioritize the accuracy of the 300°C pre-calcination stage to ensure complete decomposition of organic residuals before sintering.

- If your primary focus is electrochemical performance: Ensure your furnace can maintain a deviation-free 900°C environment for the full 10 hours to guarantee high crystallinity and short diffusion paths.

Mastering the thermal profile is the single most effective way to unlock the high-voltage potential of spinel LNMO materials.

Summary Table:

| Synthesis Stage | Temperature | Duration | Primary Function |

|---|---|---|---|

| Pre-Calcination | 300°C | Initial Phase | Organic decomposition & precursor preparation |

| Sintering | 900°C | 10 Hours | Phase transformation, crystallization & morphology shaping |

| Final Result | N/A | N/A | High-crystallinity spinel LNMO with short ion diffusion paths |

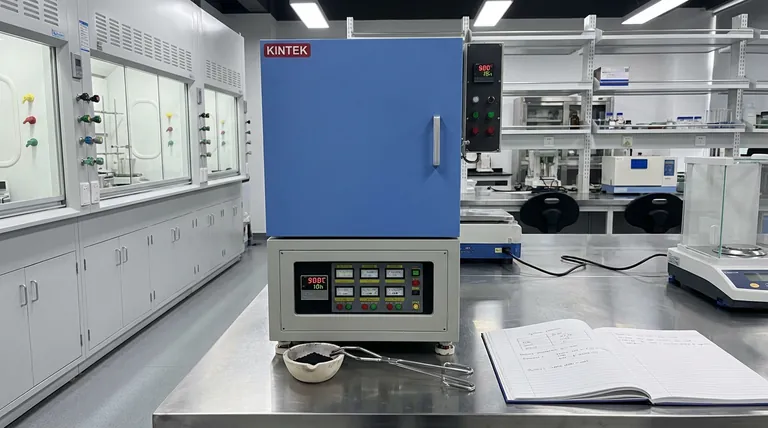

Elevate Your Battery Material Research with KINTEK

Precision is the difference between a failed batch and a high-performance cathode. KINTEK’s advanced laboratory muffle furnaces provide the thermal stability and uniform heating required for the rigorous 900°C sintering of LNMO and other advanced battery materials.

Backed by expert R&D and world-class manufacturing, KINTEK offers a full suite of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are synthesizing high-voltage spinels or exploring next-gen energy storage, our systems are fully customizable to meet your unique lab requirements.

Ready to achieve superior crystallinity and electrochemical stability? Contact our furnace experts today to find the perfect thermal solution for your laboratory.

Visual Guide

References

- So Young Choi, Hyun Deog Yoo. Synthesis and Electrochemical Properties of the Li3PO4-Coated LiNi0.5Mn1.5O4 Cathode Materials for High-Voltage Lithium-Ion Batteries. DOI: 10.3390/en18133387

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What features might advanced muffle furnace models include? Enhance Precision, Safety, and Efficiency

- How are muffle furnaces used in ceramic material processing? Unlock Precision Sintering for High-Performance Ceramics

- What is the purpose of ashing furnaces? Achieve Precise Ash Analysis for Material Quality

- What are the recommended heating and cooling protocols for a muffle furnace? Ensure Longevity and Safety in Your Lab

- What process conditions does a muffle furnace provide for rGO reduction? Master Graphene Oxide Thermal Processing

- What are the key differences between a muffle furnace and a vacuum furnace? Choose the Right Furnace for Your Lab

- What is a muffle furnace and how is it related to laboratory furnaces? Discover Precision Heating for Your Lab

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.