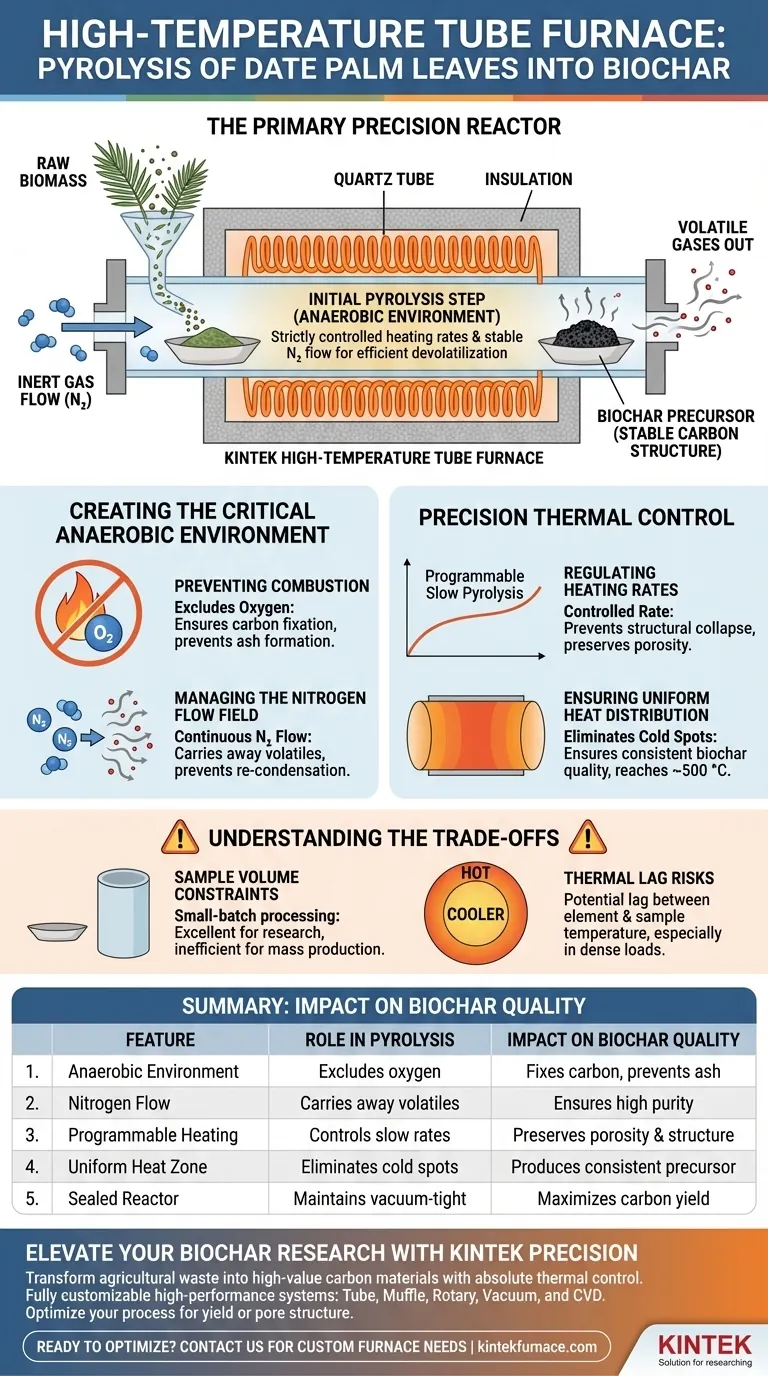

A high-temperature tube furnace serves as the primary precision reactor for the initial pyrolysis of date palm leaf biomass. It creates a strictly controlled, anaerobic environment where precise heating rates and stable nitrogen flow allow for efficient devolatilization, transforming the raw biomass into a high-quality biochar precursor with a stable carbon structure.

The Core Takeaway The tube furnace is not merely a heater; it is a control vessel that dictates the quality of the final product. By isolating the biomass from oxygen and regulating thermal exposure, it forces the material to carbonize rather than combust, which is the fundamental requirement for fixing carbon and establishing a high-porosity structure.

Creating the Critical Anaerobic Environment

The most significant role of the tube furnace is the exclusion of oxygen during the heating process.

Preventing Combustion

To convert date palm leaves into biochar, the material must undergo thermal decomposition, not burning.

The tube furnace utilizes a sealed cylindrical chamber to maintain a vacuum-tight environment. This prevents outside air from entering the reaction zone, ensuring the carbon within the biomass is fixed into a solid product rather than turning into ash.

Managing the Nitrogen Flow Field

The furnace does not just remove air; it replaces it with an inert gas, typically nitrogen.

A stable nitrogen flow field is essential for devolatilization. As the biomass heats up, it releases volatile gases. The continuous nitrogen flow carries these volatiles away, preventing them from re-condensing on the sample and ensuring a pure carbon transformation.

Precision Thermal Control

The quality of biochar derived from lignocellulosic biomass (like date palm leaves) depends heavily on how heat is applied.

Regulating Heating Rates

The tube furnace allows for programmable heating profiles, which are critical for slow pyrolysis.

By controlling how fast the temperature rises, the furnace ensures the biomass decomposes gradually. This controlled rate prevents the structural collapse of the material, preserving the natural porosity of the date palm leaves.

Ensuring Uniform Heat Distribution

The cylindrical design, wrapped with heating coils (often resistance wire or ceramic elements), ensures the sample is heated evenly.

This uniformity eliminates "cold spots" where conversion might be incomplete. It ensures that every part of the biomass sample reaches the target temperature—often around 500 °C for this specific application—resulting in a consistent biochar precursor.

Understanding the Trade-offs

While the tube furnace is the gold standard for laboratory-scale pyrolysis and material characterization, it has specific limitations you must consider.

Sample Volume Constraints

Tube furnaces are designed for small-batch processing.

The geometry of the tube limits the amount of date palm biomass you can treat at one time. This makes them excellent for research and establishing baseline parameters, but inefficient for mass production.

Thermal Lag Risks

Although the furnace controls the temperature of the heating elements precisely, there can be a lag between the element temperature and the sample temperature.

If the sample boat is too large or packed too densely, the inner layers of the biomass may not reach the target temperature simultaneously with the outer layers, leading to heterogeneous biochar quality.

Making the Right Choice for Your Goal

When employing a tube furnace for date palm leaf pyrolysis, your operational parameters should dictate your approach.

- If your primary focus is Structural Integrity: Prioritize a slow, consistent heating rate to maximize devolatilization without collapsing the pore structure.

- If your primary focus is Carbon Yield: Ensure the nitrogen flow is continuous and the seal is absolute to prevent even trace amounts of oxygen from reducing your solid output.

The tube furnace is the foundational tool that bridges the gap between raw organic waste and high-value carbon materials.

Summary Table:

| Feature | Role in Pyrolysis of Date Palm Leaves | Impact on Biochar Quality |

|---|---|---|

| Anaerobic Environment | Excludes oxygen to prevent combustion | Fixes carbon and prevents ash formation |

| Nitrogen Flow | Carries away volatile gases (Devolatilization) | Ensures high purity and prevents re-condensation |

| Programmable Heating | Controls slow pyrolysis heating rates | Preserves natural porosity and structural integrity |

| Uniform Heat Zone | Eliminates cold spots via cylindrical design | Produces consistent, homogeneous biochar precursor |

| Sealed Reactor | Maintains vacuum-tight thermal decomposition | Maximizes carbon yield and solid output quality |

Elevate Your Biochar Research with KINTEK Precision

Transforming agricultural waste like date palm leaves into high-value carbon materials requires absolute thermal control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific lab requirements.

Whether you are focusing on maximizing carbon yield or preserving complex pore structures, our advanced high-temperature furnaces provide the stable, anaerobic environment your research demands.

Ready to optimize your pyrolysis process? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Ebrahim H. Al‐Ghurabi, Mohammad Asif. Optimizing the synthesis of nanoporous activated carbon from date-palm waste for enhanced CO2 capture. DOI: 10.1038/s41598-025-00498-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a two-stage sintering process in a tube furnace contribute to high-performance sodium-ion battery cathodes?

- How does a tube furnace improve the crystal structure of zinc oxide thin films? Achieve High-Performance Crystallinity

- How does sample handling differ between vertical and horizontal tube furnaces? Choose the Right Furnace for Your Lab

- What is the typical workflow when using a multi gradient experimental tube furnace? Master Precision Heating for Your Lab

- How does the heat treatment temperature within a tube furnace affect TiO2 and nickel foam bonding? Maximize Durability

- What are the specific requirements for quartz tubes used in fixed-bed reactors? Optimize Your CeAlOx/Ni-Foam Performance

- What is the technical value of using an industrial-grade tube furnace for titania nanotubes? Enhance Crystal Performance