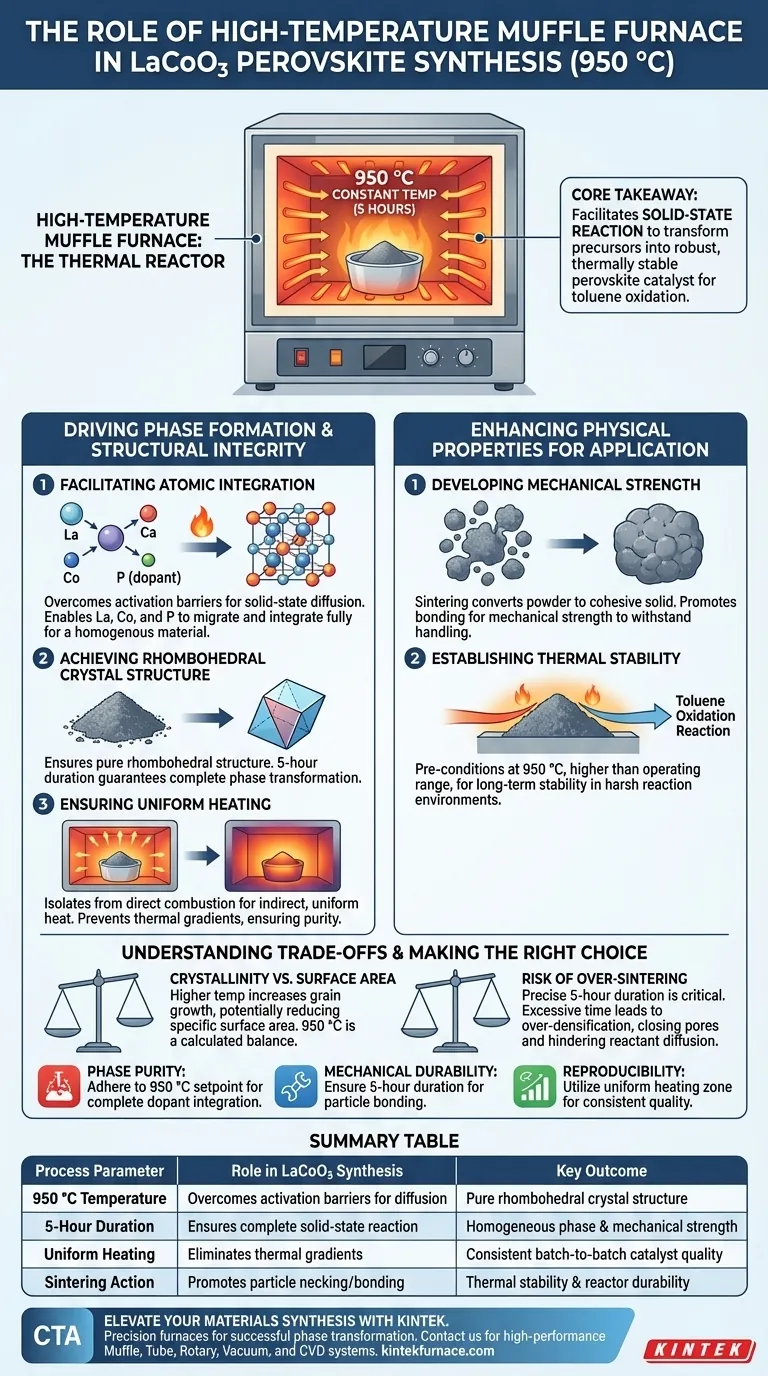

A high-temperature muffle furnace serves as the precise thermal reactor required to stabilize the LaCoO3 perovskite structure. It acts as a controlled environment that maintains a constant 950 °C for five hours, providing the thermal energy needed to drive atomic diffusion. This process integrates lanthanum, cobalt, and dopants like phosphorus into a single, pure rhombohedral crystal lattice.

Core Takeaway The muffle furnace is not merely a heating device; it is the tool that facilitates the solid-state reaction required to transform raw precursors into a mechanically robust and thermally stable perovskite catalyst capable of efficient toluene oxidation.

Driving Phase Formation and Structural Integrity

Facilitating Atomic Integration

At 950 °C, the furnace provides sufficient energy to overcome activation barriers for solid-state diffusion.

This heat allows distinct elements—specifically lanthanum, cobalt, and phosphorus—to migrate and integrate fully into the crystal lattice. This atomic rearrangement is essential for creating a homogenous material rather than a mixture of separate oxides.

Achieving the Rhombohedral Crystal Structure

The primary role of this specific thermal treatment is to ensure the formation of a pure rhombohedral structure.

Without the sustained 950 °C environment, the material may fail to crystallize correctly or may retain unstable intermediate phases. The five-hour duration ensures the phase transformation is complete throughout the bulk of the material.

Ensuring Uniform Heating

Muffle furnaces are designed to isolate the material from direct fuel combustion, providing indirect, uniform heat.

This uniformity is critical during the sintering process to prevent thermal gradients. Uneven heating could lead to inconsistent crystal growth or internal stresses that compromise the purity of the perovskite phase.

Enhancing Physical Properties for Application

Developing Mechanical Strength

The sintering process converts loose powder compacts into a cohesive solid mass.

By heating the material below its melting point, the furnace promotes necking and bonding between particles. This imparts the mechanical strength necessary for the catalyst to withstand physical handling and reactor loading without crumbling.

Establishing Thermal Stability

The treatment at 950 °C pre-conditions the material for harsh operating environments.

By synthesizing the material at a temperature higher than its intended operating range, the furnace ensures the catalyst remains thermally stable. This stability is vital for long-term performance in toluene oxidation reactions, where the catalyst must resist degradation over time.

Understanding the Trade-offs

Balancing Crystallinity and Surface Area

While high-temperature sintering ensures a stable crystal structure, it presents a natural trade-off regarding surface area.

Higher temperatures promote grain growth, which can reduce the specific surface area available for catalytic reactions. The 950 °C parameter is a calculated balance: high enough to ensure phase purity and stability, but controlled to maintain catalytic activity.

The Risk of Over-Sintering

Precise control of the furnace duration (five hours) is as critical as the temperature.

Extending the process beyond the necessary time can lead to excessive densification. This closes off porosity, potentially hindering the diffusion of reactants (like toluene) to the active sites within the catalyst structure.

Making the Right Choice for Your Goal

To maximize the effectiveness of the LaCoO3 synthesis, apply the furnace parameters based on your specific catalytic requirements:

- If your primary focus is Phase Purity: Adhere strictly to the 950 °C setpoint to ensure the complete integration of dopants like phosphorus into the rhombohedral lattice.

- If your primary focus is Mechanical Durability: Ensure the five-hour duration is met to allow sufficient particle bonding and structural consolidation for long-term use.

- If your primary focus is Reproducibility: Utilize the muffle furnace's uniform heating zone to eliminate thermal gradients that cause batch-to-batch inconsistencies.

The muffle furnace converts a chemical potential into a structural reality, ensuring your catalyst is not just chemically correct, but physically capable of performing the job.

Summary Table:

| Process Parameter | Role in LaCoO3 Synthesis | Key Outcome |

|---|---|---|

| 950 °C Temperature | Overcomes activation barriers for diffusion | Pure rhombohedral crystal structure |

| 5-Hour Duration | Ensures complete solid-state reaction | Homogeneous phase & mechanical strength |

| Uniform Heating | Eliminates thermal gradients | Consistent batch-to-batch catalyst quality |

| Sintering Action | Promotes particle necking/bonding | Thermal stability & reactor durability |

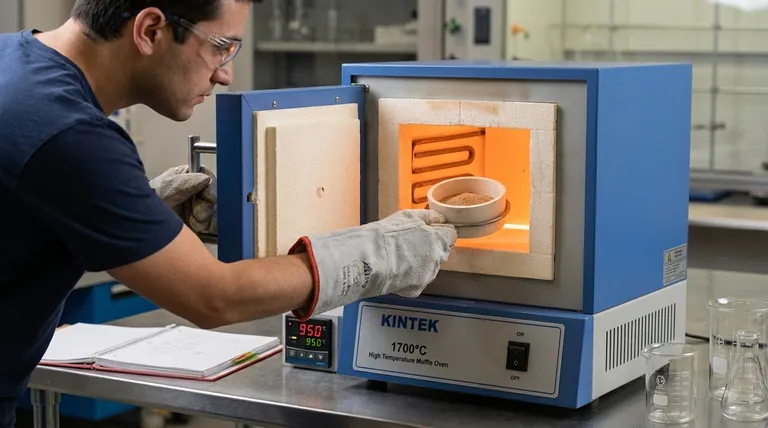

Elevate Your Materials Synthesis with KINTEK

Precision is the difference between a successful phase transformation and a failed batch. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your specific temperature and atmospheric requirements. Whether you are synthesizing LaCoO3 perovskites or advanced ceramics, our furnaces provide the thermal stability and uniformity your research demands.

Ready to optimize your sintering process? Contact us today to find your perfect furnace solution!

Visual Guide

References

- Li Yang, Zongping Shao. Rational Design of a Perovskite‐Type Catalyst for Toluene Oxidation Via Simultaneous Phosphorus Doping and Post‐Synthesis Acidic Etching. DOI: 10.1002/eem2.70115

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the application of a Muffle Furnace in biochar characterization? Master Ash Analysis & Pyrolysis Control

- What is the design feature of the furnace chamber and frame in a muffle furnace? Discover the Key to Durability

- What are some additional applications of muffle furnaces? Discover Versatile Uses in Labs and Industry

- What are the primary applications of muffle furnaces? Essential for Material Analysis and Heat Treatment

- How does a muffle furnace facilitate the direct thermal polymerization of melamine? Master g-C3N4 Synthesis Today

- How does chamber size affect muffle furnace selection? Ensure Precision with the Right Fit

- What role does a high-temperature muffle furnace play in the preparation of SrNbO3 ceramic targets? Synthesis Explained

- What is the primary function of a muffle furnace in g-C3N4/Bi2WO6 preparation? Expert Guide to Thermal Synthesis