A high-temperature muffle furnace serves as the definitive tool for phase transformation and purification in the green synthesis of Titanium Dioxide (TiO2) nanoparticles. Its primary role is to execute the critical annealing stage, typically at temperatures around 400°C. This thermal treatment is responsible for converting the initial precursor material into a stable, crystalline structure while simultaneously eliminating organic residues derived from the synthesis process.

The muffle furnace drives the essential transition from an amorphous, organic-rich precursor to a pure, crystalline anatase phase. By providing a controlled high-temperature environment, it ensures the final nanoparticles possess the necessary structural integrity and purity for application.

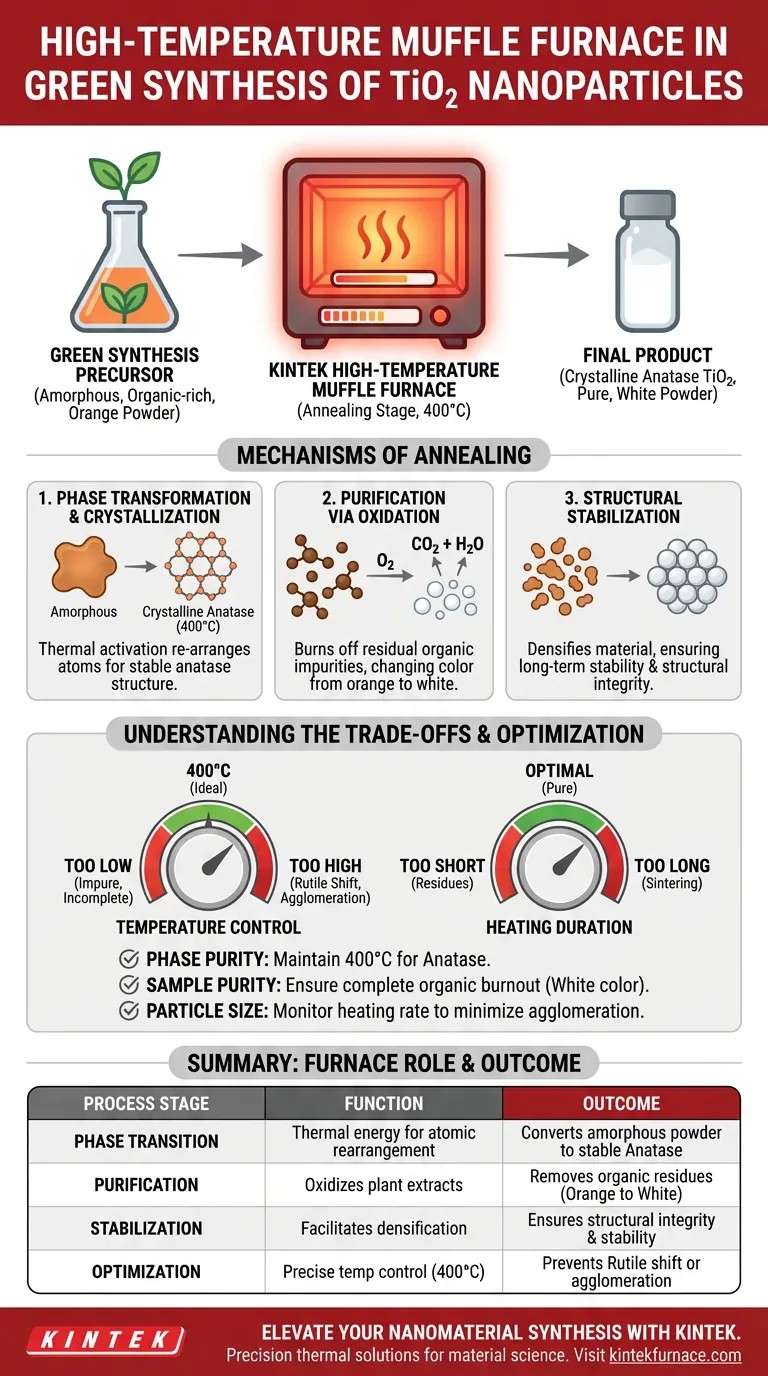

The Mechanism of Annealing in Green Synthesis

The green synthesis method typically utilizes plant extracts, which leaves the initial material in a transitional state. The muffle furnace acts as the catalyst for two major physical and chemical changes.

1. Phase Transformation and Crystallization

The initial product obtained from green synthesis is often an amorphous powder with an orange hue.

Subjecting this powder to approximately 400°C in the muffle furnace provides the thermal activation energy required for crystallization.

This heat treatment facilitates the rearrangement of atoms, transforming the powder into the anatase phase, a specific and highly stable crystalline form of Titanium Dioxide.

2. Purification via Oxidation

Green synthesis relies on biological agents, such as plant extracts, to reduce and stabilize the metal ions. However, these organic compounds remain within the precursor powder.

The high-temperature environment of the muffle furnace effectively burns off these residual organic impurities.

This purification process is visually observable; as the organic matter is removed and crystallization occurs, the powder shifts color from orange to white.

3. Structural Stabilization

Beyond simple phase changes, the furnace ensures the long-term stability of the nanoparticle.

The annealing process densifies the material and improves its structural integrity.

Without this step, the nanoparticles would likely remain unstable and retain distinct organic contaminants that could interfere with their optical or catalytic properties.

Understanding the Trade-offs

While the muffle furnace is indispensable, precise control over the operating parameters is required to avoid compromising the material.

Temperature Sensitivity and Phase Control

The temperature must be maintained strictly around the target setpoint (e.g., 400°C).

If the temperature is too low, the organic impurities may not fully decompose, resulting in lower purity and an incomplete transition to the crystalline phase.

Conversely, excessive temperatures (often significantly above 600°C, as noted in general calcination principles) can induce a phase transition from anatase to rutile, which may not be desired depending on the intended application.

Uniformity vs. Agglomeration

The furnace ensures uniform heat transfer, which is critical for consistent crystallization throughout the sample.

However, prolonged exposure to high heat can sometimes lead to the sintering of particles, causing them to clump together (agglomerate). This reduces the effective surface area of the nanoparticles, potentially diminishing their reactivity.

Making the Right Choice for Your Goal

To maximize the efficacy of the muffle furnace in your synthesis process, align your thermal treatment with your specific objectives.

- If your primary focus is Phase Purity (Anatase): Strictly maintain the annealing temperature at 400°C to secure the anatase structure without risking a shift to the rutile phase.

- If your primary focus is Sample Purity: Ensure the duration of the annealing process is sufficient to fully oxidize all plant-based organic residues, confirmed by the complete color change to white.

- If your primary focus is Particle Size: Monitor the heating rate and duration carefully to achieve crystallization while minimizing the time available for particles to sinter and agglomerate.

The muffle furnace is not merely a heating device; it is the gatekeeper that determines the final purity, color, and crystalline identity of your Titanium Dioxide nanoparticles.

Summary Table:

| Process Stage | Function of Muffle Furnace | Outcome of Thermal Treatment |

|---|---|---|

| Phase Transition | Provides thermal energy for atomic rearrangement | Converts amorphous powder to stable Anatase phase |

| Purification | Oxidizes and burns off biological plant extracts | Removes organic residues, changing color from orange to white |

| Stabilization | Facilitates material densification | Ensures structural integrity and long-term nanoparticle stability |

| Optimization | Precise temperature control (typically 400°C) | Prevents unwanted Rutile phase shift or particle agglomeration |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is the difference between a successful synthesis and a failed experiment. KINTEK provides industry-leading thermal solutions designed for the rigorous demands of material science. Backed by expert R&D and world-class manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique research or production needs.

Whether you are refining green synthesis protocols or scaling up production of Titanium Dioxide, KINTEK high-temperature furnaces deliver the uniformity and control you need to achieve perfect phase purity every time.

Ready to optimize your thermal processes? Contact our laboratory specialists today to find the ideal furnace for your application.

Visual Guide

References

- Archana Rana, Shailesh Narain Sharma. Multifaceted properties of TiO<sub>2</sub> nanoparticles synthesized using <i>Mangifera indica</i> and <i>Azadirachta indica</i> plant extracts: antimicrobial, antioxidant, and non-linear optical activity investigation for sustainable agricultural applica. DOI: 10.1039/d3ma00414g

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What precautions should be taken when melting samples with alkaline substances? Safeguard Your Furnace from Corrosion

- What is the function of a forced convection oven during the preparation of TiH2 powder from TiO2? Ensure Purity Now

- How are muffle furnaces critical in the semiconductor industry? Essential for Precise Thermal Processing in Chip Fabrication

- How does the programmed temperature control of a muffle furnace influence the formation of g-C3N4 semiconductors?

- How was the muffle furnace used in environmental sample analysis? Master Sample Purification for Accurate Results

- How do you maintain a muffle furnace? Ensure Longevity and Safety with Proven Tips

- What personal protective equipment (PPE) is recommended for benchtop furnace use? Ensure Lab Safety with Proper Gear

- How does the muffle furnace ensure uniform heating? Achieve Precise, Even Heat for Your Lab