In environmental science, a muffle furnace is primarily used for the high-temperature combustion of samples, a process known as ashing. This technique effectively removes organic matter from environmental samples—such as soil, water residue, or sludge—at temperatures exceeding 500°C. By eliminating these organic substances, which can interfere with testing, analysts can achieve a much higher degree of accuracy when measuring inorganic pollutants like heavy metals.

The core function of a muffle furnace in environmental analysis is not to measure a substance, but to prepare a sample for measurement. It purifies the sample by thermally removing organic interference, thereby isolating the inorganic components for highly accurate analysis.

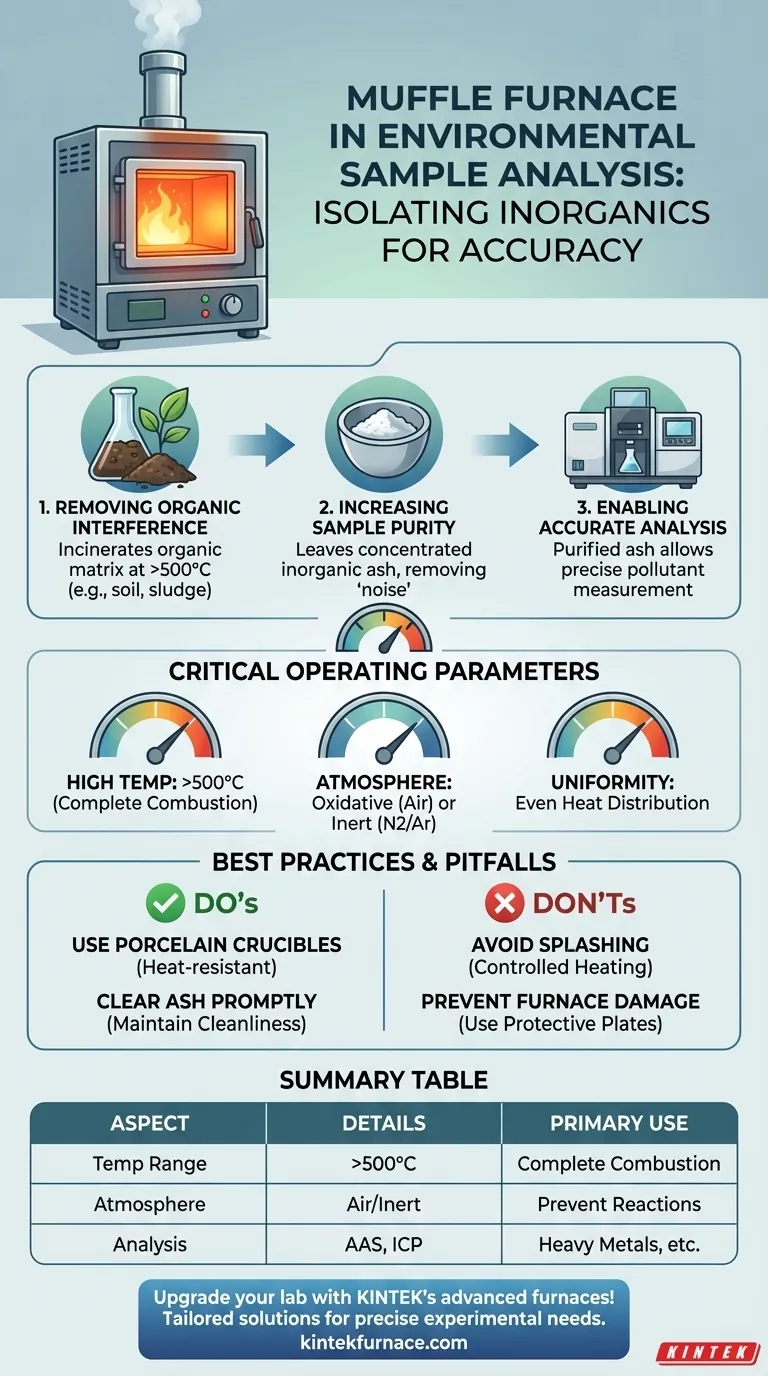

The Core Principle: Isolating Analytes for Accurate Measurement

The primary challenge in analyzing many environmental pollutants, particularly heavy metals, is that they exist in a complex matrix of organic material. This organic "noise" must be removed to get a clear signal from the analyte you intend to measure.

Removing Organic Interference

Environmental samples from soil, sediment, or wastewater are rich in organic compounds. During analysis, these compounds can react with chemical reagents or interfere with instrument signals, masking the presence and concentration of inorganic pollutants. The muffle furnace incinerates this organic matrix, converting it to carbon dioxide and water vapor.

Increasing Sample Purity

By burning off the organic fraction, the process leaves behind a concentrated ash composed almost entirely of the inorganic constituents of the original sample. This dramatic increase in purity is the key to reliable results.

Enabling Accurate Analysis

With the organic interference gone, the resulting ash can be dissolved and analyzed using highly sensitive techniques like Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma (ICP) analysis. The data generated from this purified sample provides strong, defensible support for pollutant tracking and environmental protection efforts.

Critical Operating Parameters for Reliable Results

Achieving accurate results is not as simple as placing a sample in a hot box. The process requires precise control over several key variables to ensure complete combustion without compromising the sample's integrity.

High-Temperature Ashing

Temperatures must be above 500°C to ensure the efficient and complete removal of all organic substances. Incomplete ashing is a common source of analytical error.

Precise Atmosphere Control

Some analyses require a specific atmosphere within the furnace. An oxidative atmosphere (air) is common for burning off organics, but an inert atmosphere (like nitrogen or argon) may be needed to prevent the target analyte from reacting with oxygen at high temperatures.

Temperature Uniformity

The furnace must provide an even temperature distribution across the entire chamber. "Hot spots" can cause localized overheating, leading to sample splashing or even the volatilization (loss) of certain analytes, while "cold spots" can result in incomplete ashing.

Understanding the Best Practices and Pitfalls

Proper protocol is essential for protecting both the sample and the equipment. Mishandling the process can lead to contaminated results or permanent damage to the furnace.

Use of Proper Labware

Samples must always be placed in high-temperature-resistant porcelain crucibles or similar inert dishes. These can withstand the extreme temperatures without reacting with the sample or degrading.

Preventing Furnace Damage

Rapid, uncontrolled heating can cause moisture in the sample to boil, leading to splashing. This not only results in sample loss but can also cause corrosive materials to bond with the furnace hearth. Placing an asbestos board or ceramic plate on the furnace floor can help protect the surface.

Maintaining a Clean Environment

Any slag, spilled ash, or metal oxides must be cleared promptly after each use. This maintains the furnace's smooth interior, prevents cross-contamination between samples, and ensures consistent heating performance over the long term.

Applying This to Your Analytical Goals

The specific protocol you use will depend on your analytical objective. The trade-off is often between speed and the highest possible level of accuracy.

- If your primary focus is routine compliance monitoring: A standardized ashing procedure at 550°C is typically sufficient to remove organics for consistent, repeatable analysis of common heavy metals.

- If your primary focus is research-grade analysis of volatile elements: You must carefully control the temperature ramp rate and may need to use a lower maximum temperature to prevent the loss of analytes like mercury or selenium.

- If your primary focus is analyzing samples with complex or reactive matrices: You may need a furnace with advanced atmosphere control to run the ashing process under an inert gas, preventing unwanted oxidation of your target compounds.

Ultimately, mastering the muffle furnace is about understanding it as a critical tool for sample purification, not just a heater.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Use | High-temperature ashing to remove organic matter from samples like soil, water residue, or sludge. |

| Temperature Range | Above 500°C for complete combustion. |

| Atmosphere Control | Oxidative (air) or inert (e.g., nitrogen) to prevent analyte reactions. |

| Sample Preparation | Uses high-temperature-resistant crucibles to avoid contamination. |

| Analysis Techniques | Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma (ICP) for accurate pollutant measurement. |

| Common Applications | Environmental monitoring, heavy metal analysis, and research on volatile elements. |

Upgrade your environmental analysis with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise matching to your unique experimental needs, enhancing accuracy in sample purification and pollutant detection. Contact us today to discuss how our furnaces can optimize your lab's efficiency and reliability!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO