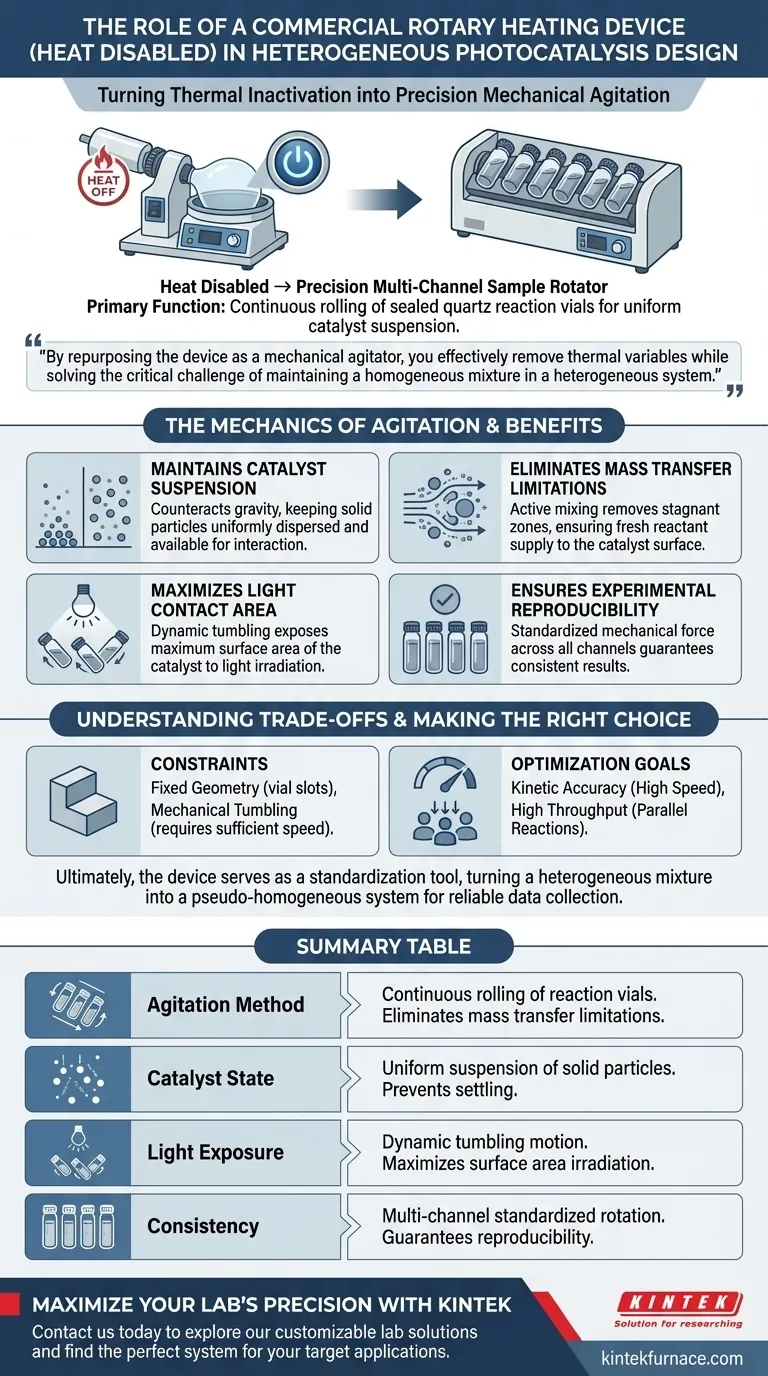

When the thermal function is disabled, a commercial rotary heating device transforms into a precision multi-channel sample rotator. Its primary mechanical function is to continuously roll sealed quartz reaction vials, ensuring that solid supported catalysts remain uniformly suspended within liquid reaction media, such as chloroform solutions.

By repurposing the device as a mechanical agitator, you effectively remove thermal variables while solving the critical challenge of maintaining a homogeneous mixture in a heterogeneous system.

The Mechanics of Agitation in Photocatalysis

In heterogeneous photocatalytic reactors, the physical state of the catalyst is just as important as the chemistry. Using a rotary device without heat addresses several fundamental engineering challenges.

Maintaining Catalyst Suspension

In a static setup, solid catalysts will naturally settle to the bottom of the vial due to gravity. This separates the catalyst from the bulk of the reactants.

Continuous rotation counteracts gravity, keeping the solid particles uniformly dispersed throughout the liquid medium. This ensures that the catalyst is always available to interact with the reactants.

Maximizing Light Contact Area

Photocatalysis is driven by photon absorption. If a catalyst settles in a pile, only the top layer is exposed to the light source.

Rolling the vials creates a tumbling motion that exposes the maximum possible surface area of the catalyst to the light source. This dynamic movement ensures every particle receives adequate irradiation.

Eliminating Mass Transfer Limitations

Reaction speed is often limited by how fast reactants can travel to the catalyst surface. This is known as the mass transfer limitation.

The continuous rolling motion acts as active mixing. This eliminates stagnant zones and ensures a fresh supply of reactants is constantly brought into contact with the catalyst surface.

Ensuring Experimental Reproducibility

Inconsistent agitation leads to erratic data. If one vial is shaken and another is static, the results cannot be compared.

The device serves as a multi-channel system, treating all vials with the exact same mechanical force. This guarantees high reproducibility of experimental results across all samples.

Understanding the Trade-offs

While effective, using a rotary heater solely for rotation does have specific constraints compared to dedicated stirring plates.

Fixed Geometry Constraints

The device typically uses pre-sized slots for specific quartz vials. Unlike a magnetic stir plate, you cannot easily change vessel sizes or geometry without changing the reactor block.

Mechanical vs. Magnetic Agitation

Rotary tumbling is excellent for suspension but differs from the vortexing created by magnetic stir bars. You must ensure the rotation speed is sufficient to prevent the solid phase from sliding along the glass rather than tumbling.

Making the Right Choice for Your Goal

To get the most out of this setup, align the device's operation with your specific experimental needs.

- If your primary focus is Kinetic Accuracy: Ensure the rotation speed is high enough to fully eliminate mass transfer limitations, proving the reaction is chemically limited rather than diffusion limited.

- If your primary focus is High Throughput Screening: Utilize the multi-channel capability to run parallel reactions, relying on the uniform mechanical action to validate that differences in yield are due to chemistry, not mixing variations.

Ultimately, the device serves as a standardization tool, turning a heterogeneous mixture into a pseudo-homogeneous system for reliable data collection.

Summary Table:

| Feature | Mechanical Role (Heat Disabled) | Benefit for Photocatalysis |

|---|---|---|

| Agitation Method | Continuous rolling of reaction vials | Eliminates mass transfer limitations and stagnant zones |

| Catalyst State | Uniform suspension of solid particles | Prevents settling and ensures consistent reactant contact |

| Light Exposure | Dynamic tumbling motion | Maximizes surface area irradiation for all catalyst particles |

| Consistency | Multi-channel standardized rotation | Guarantees experimental reproducibility across all samples |

Maximize Your Lab's Precision with KINTEK

Whether you need precision rotation for heterogeneous systems or high-performance heating for chemical synthesis, KINTEK delivers the reliability your research demands. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique experimental needs.

Don't let inconsistent agitation or poor temperature control compromise your data. Contact us today to explore our customizable lab solutions and find the perfect high-temperature or mechanical system for your target applications.

Visual Guide

References

- Julia Ong, J. C. Scaiano. Comparison of Composite Materials Designed to Optimize Heterogeneous Decatungstate Oxidative Photocatalysis. DOI: 10.3390/molecules30173597

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do rotary kilns demonstrate energy efficiency? Maximize Heat Transfer and Fuel Flexibility

- How is the Rotary Tube Tilt Furnace used in carbon activation processes? Achieve Precise Control for High-Quality Activated Carbon

- What is a Rotary Tube Tilt Furnace and how does it differ from traditional static furnaces? Achieve Uniform Heating for Powders and Granules

- What is a rotary furnace used for? Achieve Uniform Heat Treatment for Powders & Granules

- What are the key features of a rotary tube furnace? Unlock Continuous, Uniform Thermal Processing

- What is the overall importance of selecting the right rotary kiln design? Boost Efficiency and Quality in Thermal Processing

- What factors should be considered when selecting a rotary tube furnace? Ensure Optimal Performance for Your Materials

- What are the advantages of rotary furnace? Achieve Superior Uniform Heating & Mixing