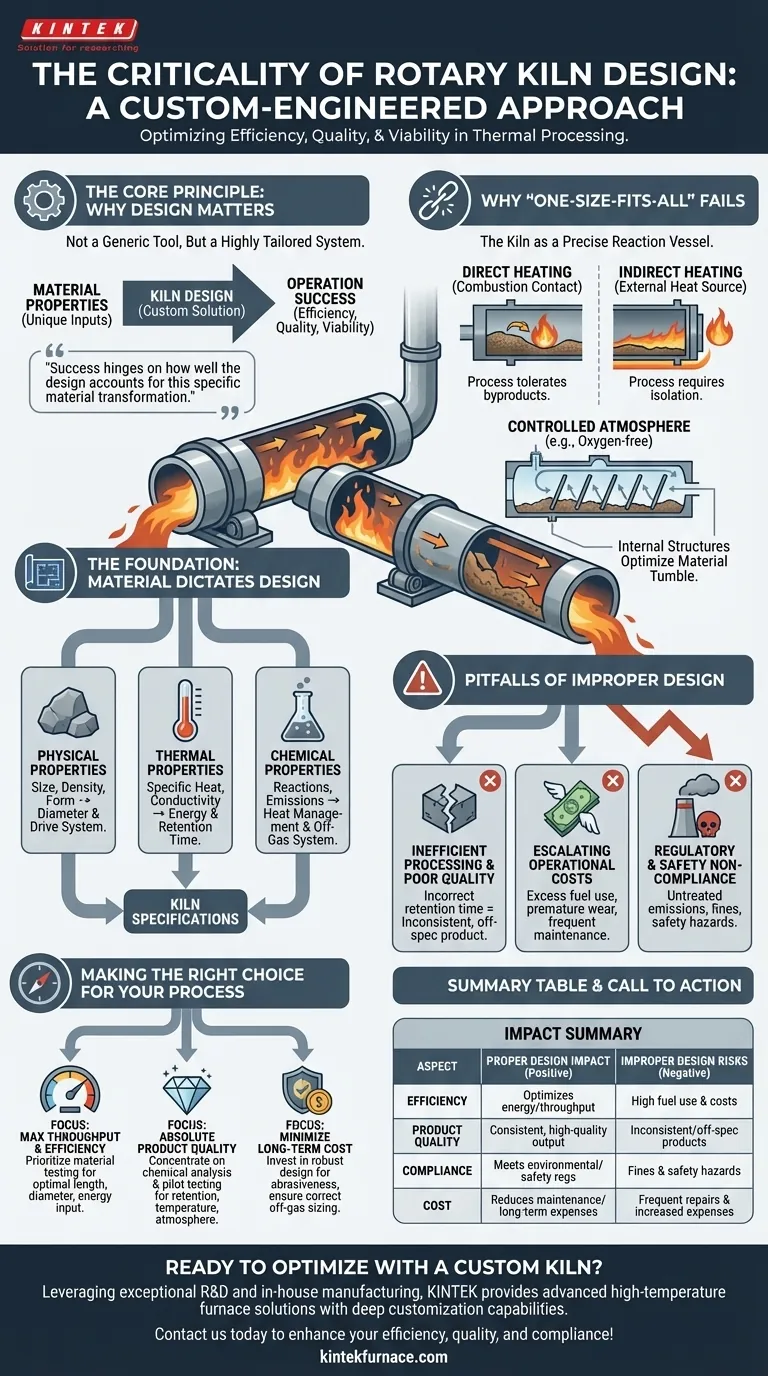

At its core, selecting the right rotary kiln design is the single most critical factor in determining the efficiency, quality, and financial viability of a thermal processing operation. An appropriate design optimizes energy consumption and product output, while an incorrect one leads to high operational costs, inconsistent quality, and potential compliance failures.

A rotary kiln is not a generic piece of equipment; it is a highly tailored system engineered around the unique physical, thermal, and chemical properties of the material it will process. The success of the entire operation hinges on how well the design accounts for this specific material transformation.

Why a "One-Size-Fits-All" Approach Fails

A rotary kiln’s primary purpose is to induce a specific physical or chemical change in a material through controlled thermal processing. Because every material behaves differently under heat, the kiln must be custom-engineered to create the perfect environment for that transformation.

The Kiln as a Precise Reaction Vessel

The kiln is a slowly rotating, inclined cylinder that moves material from an inlet to a discharge end. This controlled movement, combined with precise heating, is what drives the desired changes.

Internal structures like dams or lifters can be added to manipulate how the material tumbles and is exposed to heat, further optimizing the process for a specific feed.

The Critical Choice: Direct vs. Indirect Heating

Kilns can be directly heated, where combustion gas comes into contact with the material, or indirectly heated, where the cylinder is heated from the outside. This choice depends entirely on whether the process chemistry can tolerate the byproducts of combustion.

Creating a Controlled Atmosphere

The design must also account for the process atmosphere. Sealed ends are crucial for maintaining specific conditions, such as an oxygen-free or carbon dioxide-rich environment, which some chemical reactions require to proceed correctly.

The Foundation: Material Characteristics Dictate Design

The design process begins not with the kiln, but with a deep analysis of the material itself. Its properties are the non-negotiable inputs that define the kiln's specifications.

Physical Properties: Size, Density, and Form

A material's particle size distribution and bulk density directly influence the kiln's diameter and the power needed for its drive system. For example, a dense material requires a more robust drive and support structure.

Pelletized or uniform feeds allow for higher gas velocities without blowing fine particles out of the system, which can enable the use of a smaller-diameter kiln.

Thermal Properties: How the Material Accepts Heat

Specific heat (a material's resistance to temperature change) and thermal conductivity (how efficiently heat moves through it) determine the total energy required and the necessary retention time.

Materials that heat slowly or conduct poorly require longer kilns or slower rotation speeds to ensure every particle reaches the target temperature.

Chemical Properties: Reactions and Emissions

A material's chemical composition is paramount. Some reactions are exothermic, meaning they release their own heat and require a design that can manage this excess energy to prevent overheating.

Furthermore, the chemical analysis predicts the composition of the exhaust gas. This is essential for designing the required off-gas treatment system to meet environmental regulations.

Understanding the Pitfalls of an Improper Design

Choosing a kiln based on generalized specifications is a recipe for inefficiency and failure. The consequences of a design that is not tailored to the specific material and process are severe and costly.

Inefficient Processing and Poor Product Quality

If the kiln is too short or the temperature profile is wrong, the material will not have the required retention time to undergo its complete transformation. This results in an inconsistent or off-spec product that fails to meet quality standards.

Escalating Operational Costs

A poorly matched kiln will consume excess fuel, as it struggles to deliver the necessary thermal energy efficiently. It may also suffer from premature wear on components like the refractory lining or drive system, leading to frequent and expensive maintenance.

Regulatory and Safety Non-Compliance

A design that fails to account for the chemical reactions will produce an exhaust gas stream that may not be properly treated. This can lead to violations of environmental permits and significant fines.

Likewise, safety systems, such as shielding against radiation or advanced process controls, must be integrated based on the specific operational hazards, and overlooking these creates risks for operators.

Making the Right Choice for Your Process

The selection process should be a data-driven engineering exercise, not a simple procurement decision. By focusing on the end goal, you can ensure the design aligns with your operational priorities.

- If your primary focus is maximizing throughput and efficiency: Prioritize comprehensive material testing to precisely determine thermal properties, which will define the optimal kiln length, diameter, and energy input.

- If your primary focus is ensuring absolute product quality: Concentrate on the chemical analysis and pilot-scale testing to perfect the retention time, temperature profile, and process atmosphere.

- If your primary focus is minimizing long-term operational cost: Invest in a robust design that accounts for material density and abrasiveness, and ensure the exhaust gas system is correctly sized to avoid future compliance issues.

Ultimately, viewing the rotary kiln as a custom-engineered solution for your specific material is the only path to a successful and profitable thermal processing operation.

Summary Table:

| Aspect | Impact of Proper Design | Risks of Improper Design |

|---|---|---|

| Efficiency | Optimizes energy consumption and throughput | High fuel use and operational costs |

| Product Quality | Ensures consistent, high-quality output | Inconsistent or off-spec products |

| Compliance | Meets environmental and safety regulations | Fines and safety hazards from non-compliance |

| Cost | Reduces long-term maintenance and operational expenses | Frequent repairs and increased expenses |

Ready to optimize your thermal processing with a custom-engineered rotary kiln? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your efficiency, quality, and compliance!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What is the retention time of a rotary kiln? Optimize Your Process Efficiency

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency