A high-temperature muffle furnace provides a rigorous, complete oxidation environment maintained at extreme temperatures, specifically between 800°C and 900°C. This intense thermal setting is engineered to ensure the total combustion and volatilization of all organic matter within biomass briquette samples, leaving only the inorganic residue for analysis.

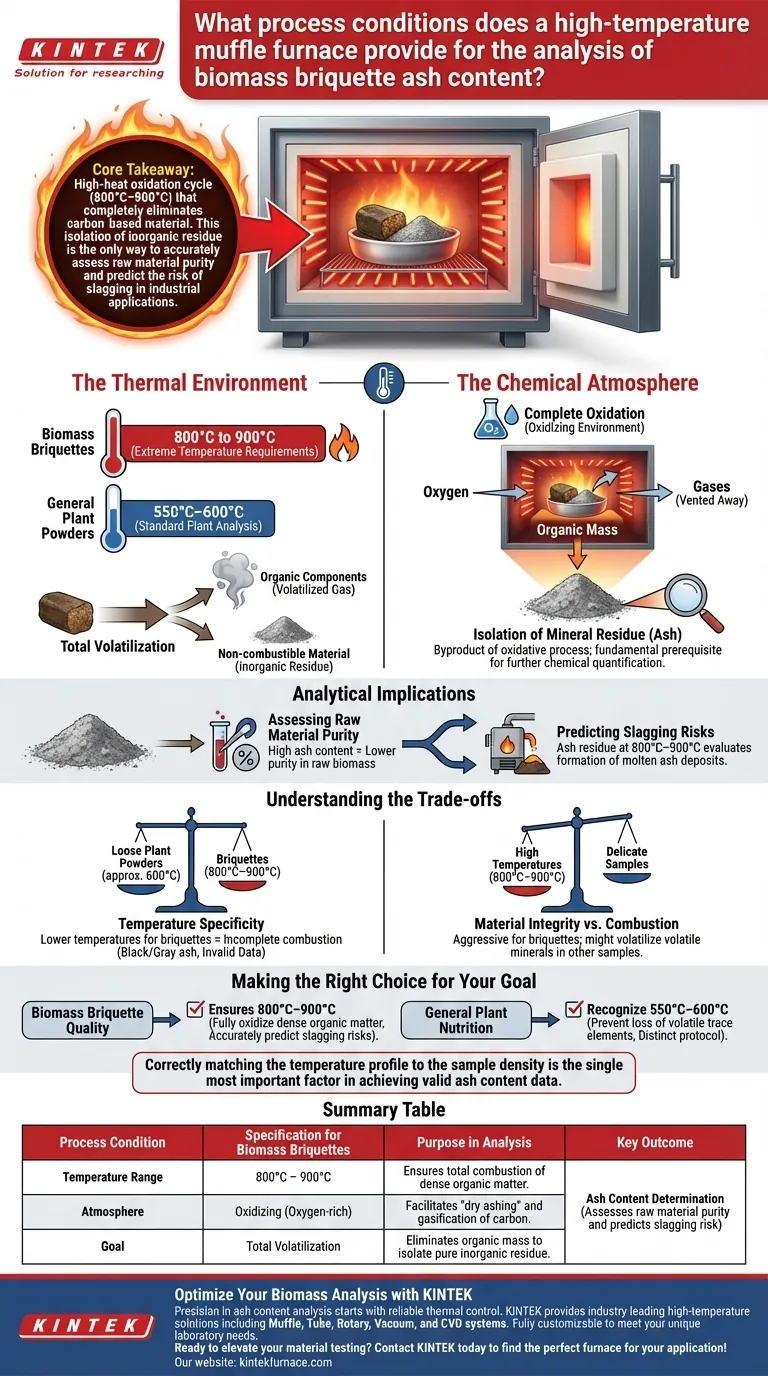

Core Takeaway The specific process condition required for biomass briquettes is a high-heat oxidation cycle (800°C–900°C) that completely eliminates carbon-based material. This isolation of inorganic residue is the only way to accurately assess raw material purity and predict the risk of slagging in industrial applications.

The Thermal Environment

Extreme Temperature Requirements

For the specific analysis of biomass briquettes, the furnace must sustain temperatures significantly higher than standard plant analysis.

While general plant powders may be processed at 550°C–600°C, biomass briquettes require a range of 800°C to 900°C.

Total Volatilization

The primary goal of this heat is the complete removal of organic components.

At these temperatures, all carbon structures are burned off and volatilized. This ensures that the remaining mass consists exclusively of non-combustible material.

The Chemical Atmosphere

Complete Oxidation

The muffle furnace does not just apply heat; it facilitates an oxidation environment.

This atmosphere allows oxygen to react thoroughly with the sample. The combination of oxygen and high heat drives the "dry ashing" process, converting organic mass into gases that are vented away.

Isolation of Mineral Residue

The byproduct of this oxidative process is the inorganic mineral residue, commonly referred to as ash.

This residue represents the non-combustible minerals originally present in the briquette. Isolating this material is the fundamental prerequisite for any further chemical quantification.

Analytical Implications

Assessing Raw Material Purity

The quantity of ash remaining after the process is a direct indicator of fuel quality.

High ash content often suggests lower purity in the raw biomass material. The furnace provides the stable conditions necessary to make this determination with high precision.

Predicting Slagging Risks

Beyond simple purity, the ash content helps predict operational behavior.

By analyzing the residue obtained at 800°C–900°C, operators can evaluate the risk of slagging—the formation of molten ash deposits—during the actual combustion of the fuel.

Understanding the Trade-offs

Temperature Specificity

It is critical to distinguish between general plant tissue analysis and biomass briquette analysis.

Applying the lower temperatures standard for loose plant powders (approx. 600°C) to briquettes may result in incomplete combustion. This yields black or gray ash containing unburned carbon, which invalidates the weight measurement and skews purity data.

Material Integrity vs. Combustion

Conversely, the high temperatures (800°C–900°C) required for briquettes are aggressive.

While necessary for briquettes, these temperatures might volatilize certain volatile minerals in other delicate samples. Therefore, adhering to the specific protocol for the material type is essential for data accuracy.

Making the Right Choice for Your Goal

Depending on your specific analytical objectives, you must verify that your furnace protocols align with the material nature.

- If your primary focus is Biomass Briquette Quality: Ensure your furnace is calibrated to reach 800°C–900°C to fully oxidize dense organic matter and accurately predict slagging risks.

- If your primary focus is General Plant Nutrition: Recognize that lower temperatures (550°C–600°C) are typically used for loose plant powders to prevent the loss of volatile trace elements, distinct from the briquette protocol.

Correctly matching the temperature profile to the sample density is the single most important factor in achieving valid ash content data.

Summary Table:

| Process Condition | Specification for Biomass Briquettes | Purpose in Analysis |

|---|---|---|

| Temperature Range | 800°C – 900°C | Ensures total combustion of dense organic matter. |

| Atmosphere | Oxidizing (Oxygen-rich) | Facilitates "dry ashing" and gasification of carbon. |

| Goal | Total Volatilization | Eliminates organic mass to isolate pure inorganic residue. |

| Key Outcome | Ash Content Determination | Assesses raw material purity and predicts slagging risk. |

Optimize Your Biomass Analysis with KINTEK

Precision in ash content analysis starts with reliable thermal control. KINTEK provides industry-leading high-temperature solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all engineered to maintain the rigorous 800°C–900°C environments required for accurate biomass characterization.

Backed by expert R&D and manufacturing, our furnaces are fully customizable to meet your unique laboratory needs, ensuring total volatilization and consistent data every time.

Ready to elevate your material testing? Contact KINTEK today to find the perfect furnace for your application!

Visual Guide

References

- Adam Yonanda, Elvianto Dwi Daryono. Optimization of Natural Adhesive Type and Concentration on Characteristics of Corn Cob Biobriquettes. DOI: 10.70609/gtech.v9i1.6194

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What specific thermal conditions must a high-temperature muffle furnace provide for BiOI to BiVO4 conversion?

- What role does a muffle furnace play in the SHS of lithium orthosilicate? Efficient Thermal Ignition Explained

- How is a muffle furnace used in laboratories for sample preparation? Master Ashing and Heat Treatment Techniques

- What is the mechanism of a high-temperature furnace in Bi-2223 sintering? Achieve Precision Phase Transformation

- How does a laboratory high-temperature box furnace influence the microstructure of H13 steel? Expert Insights

- What role does a high-temperature muffle furnace play in ZnO/CuO preparation? Master Nanocomposite Synthesis

- What role does a high-temperature muffle furnace play during the carbonization of fish scales? Achieve Thermal Precision

- How does a muffle furnace differ from a conventional oven? Key Differences for High-Temperature Precision