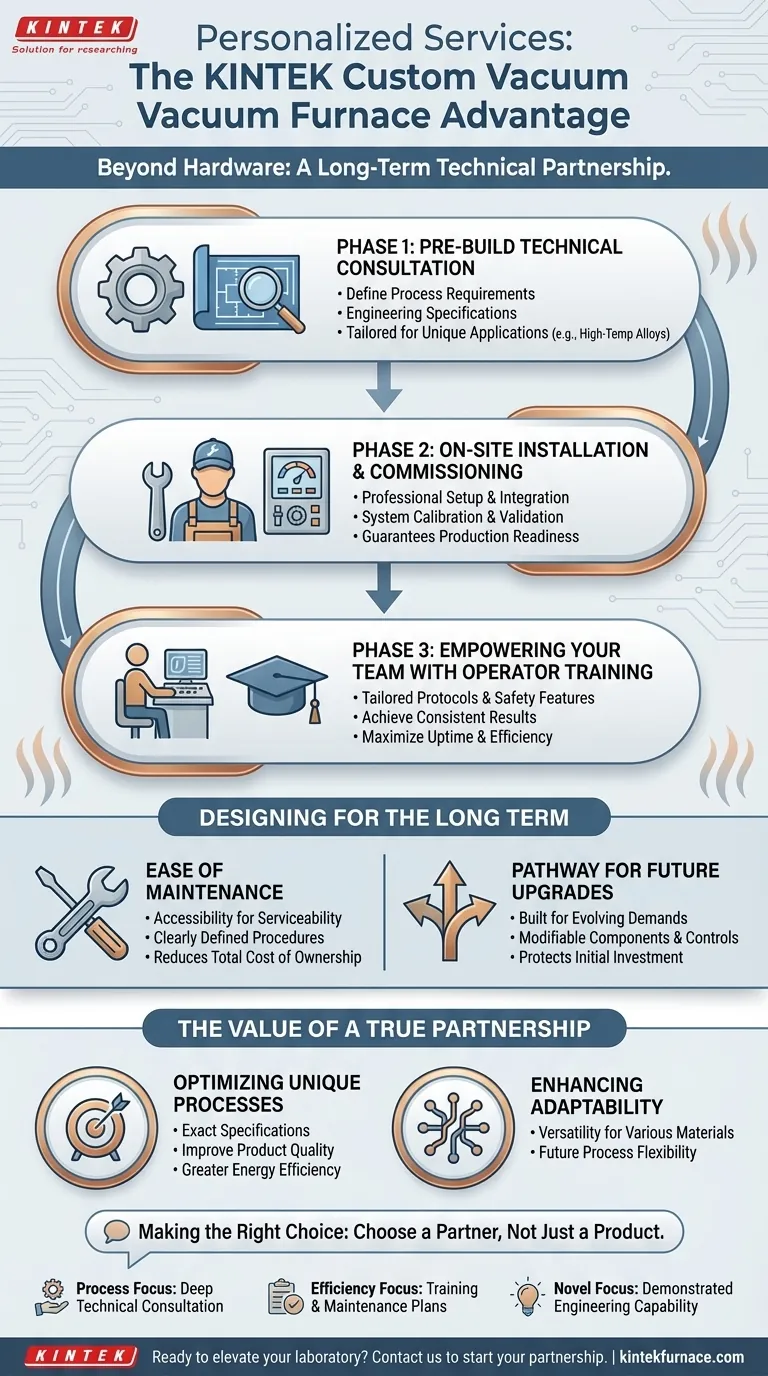

Beyond the hardware itself, a customized vacuum furnace includes a suite of personalized services designed to integrate the equipment into your specific workflow. Key services typically include in-depth technical consultation before the build, professional on-site installation and commissioning, and comprehensive operator training to ensure the furnace is used safely and efficiently from day one.

The personalized services provided with a custom vacuum furnace are not optional extras; they represent a fundamental shift from a simple equipment purchase to a long-term technical partnership. This support system is essential for integrating a unique piece of machinery into your production environment and maximizing its value over its entire lifecycle.

The Service Lifecycle of a Custom Furnace

The support for a custom furnace is best understood as a multi-phase process that begins long before the equipment arrives at your facility and extends far into its operational life.

Phase 1: Pre-Build Technical Consultation

This is the foundational stage where "personalization" truly begins. The manufacturer's technical experts work with you to translate your specific process requirements into concrete engineering specifications.

This involves defining parameters for your unique applications, such as heat treatment cycles for high-temperature alloys, stainless steel, or titanium alloys. If your project is experimental or has atypical demands, this consultation ensures the final design can meet those unique challenges.

Phase 2: On-Site Installation and Commissioning

Unlike standard equipment, a custom furnace requires meticulous integration. Professional installation ensures the furnace is correctly situated, connected to utilities, and functions within your facility's infrastructure.

Commissioning is the critical next step. Technicians will run initial cycles, calibrate the system for your specific process, and validate that the furnace performs exactly as designed. This guarantees the machine is ready for production and meets all quality requirements.

Phase 3: Empowering Your Team with Operator Training

A custom furnace has unique operational protocols. The provided training is tailored specifically to your machine, its controls, and its safety features.

This ensures your operators can run the furnace efficiently, achieve consistent results, and perform routine checks, which increases equipment uptime and overall production satisfaction.

Designing for the Long Term

A key aspect of personalization is ensuring the furnace remains a valuable asset for years to come. This involves designing for maintainability and future growth.

Ease of Maintenance

Custom furnaces are engineered with long-term serviceability in mind. Components are arranged for accessibility, and maintenance procedures are clearly defined. This proactive approach simplifies upkeep and reduces the total cost of ownership.

A Pathway for Future Upgrades

Your production demands may evolve. A well-designed custom furnace is not a static asset; it is built with future modifications in mind. This allows you to upgrade components or control systems as needed to meet new process requirements, protecting your initial investment.

Understanding the Value of a True Partnership

Opting for a custom furnace is a strategic decision that prioritizes process optimization over a one-size-fits-all solution. The personalized services are what make this strategy successful.

Optimizing Your Unique Process

The primary advantage is a furnace built to your exact specifications. This level of tailoring helps optimize production cycles, improve final product quality, and can even lead to greater energy efficiency compared to a general-purpose model.

Enhancing Production Adaptability

While built for a specific need, these furnaces can be designed for versatility. By planning for it during the consultation phase, your furnace can be capable of handling a variety of materials and heat treatment processes, giving you greater production flexibility.

Making the Right Choice for Your Goal

When choosing a custom furnace, you are choosing a technical partner as much as a product. Use these points to evaluate your options.

- If your primary focus is process optimization: Ensure the provider's technical consultation is deep enough to translate your unique material and quality requirements into concrete design specifications.

- If your primary focus is long-term operational efficiency: Scrutinize the plans for operator training, ease of maintenance, and the defined paths for future upgrades.

- If your primary focus is a novel or experimental application: Prioritize a partner with demonstrated engineering capability to build for atypical specifications and validate performance during on-site commissioning.

Ultimately, the right suite of personalized services transforms a major capital expenditure into a strategic, long-term asset for your operation.

Summary Table:

| Service Phase | Key Activities | Benefits |

|---|---|---|

| Pre-Build Consultation | Define process requirements, engineering specs | Ensures design meets unique application needs |

| Installation & Commissioning | On-site setup, calibration, performance validation | Guarantees furnace readiness and quality |

| Operator Training | Tailored protocols, safety, efficiency training | Enhances uptime and consistent results |

| Long-Term Support | Maintenance design, upgrade pathways | Reduces costs and protects investment |

Ready to elevate your laboratory with a custom vacuum furnace? KINTEK offers personalized services tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your experimental goals, from initial consultation to long-term support. Contact us today to start your partnership and maximize your operational efficiency!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- What is a vacuum hot press furnace and what are its primary uses? Unlock High-Performance Material Processing

- What safety precautions and maintenance requirements are necessary for vacuum hot press furnaces? Ensure Safe, Reliable Operation

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What are the advantages of using vacuum hot press furnaces over traditional furnaces? Achieve Superior Material Quality and Performance