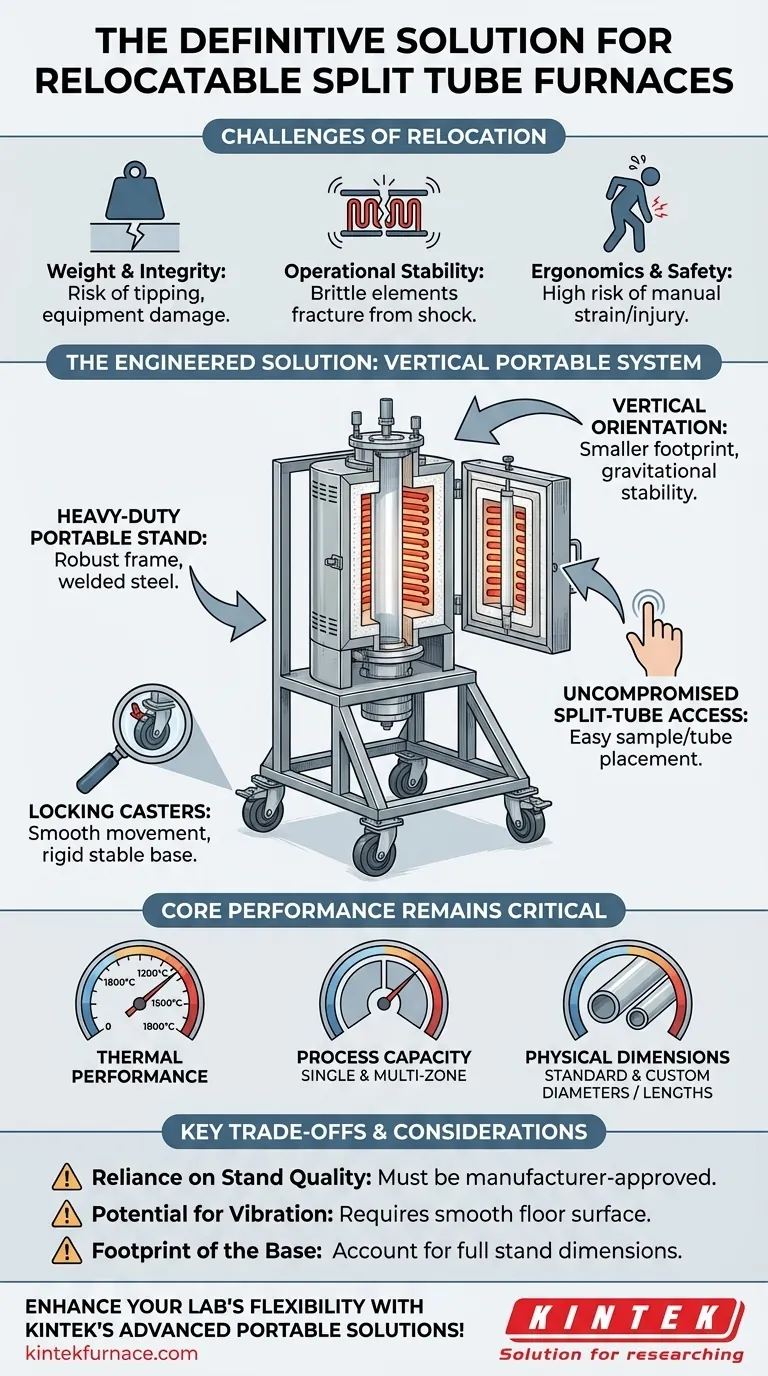

For split tube furnaces that require frequent relocation, the definitive solution is a purpose-built vertical configuration mounted on a heavy-duty portable stand. This design specifically addresses the challenges of moving sensitive, high-temperature equipment by integrating mobility features like robust casters directly into a stable, ergonomic frame, allowing for easy and safe repositioning within a lab or facility.

While a standard furnace is a static piece of equipment, the core challenge is achieving mobility without compromising operational stability or safety. The solution lies not in a simple cart, but in an integrated system where a vertical furnace orientation is paired with a heavy-duty, purpose-built portable stand.

Why Portability Is a Challenge for Furnaces

Simply placing a standard furnace on a generic cart is often impractical and unsafe. Understanding the inherent challenges clarifies why a specialized configuration is necessary.

Weight and Structural Integrity

Split tube furnaces are heavy, constructed from dense insulation and robust steel casings. An inadequate stand can buckle or tip, posing a significant safety hazard and risking damage to the equipment.

Operational Stability

Heating elements, especially those made from materials like Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2), can be brittle. Vibrations and shocks during movement can cause fractures, leading to premature failure and costly repairs.

Ergonomics and Safety

Moving heavy equipment manually increases the risk of strain and injury. A properly designed portable stand provides the correct height and leverage for safe movement by a single operator.

The Engineered Solution: The Vertical Portable Stand

The industry-standard solution directly addresses these challenges through a thoughtful combination of orientation and hardware.

The Heavy-Duty Portable Stand

This is the cornerstone of the system. It is a robust, welded steel frame equipped with locking casters. These casters allow for smooth movement across a floor and can be securely locked to provide a rigid, stable base during operation.

The Vertical Furnace Orientation

Mounting the furnace vertically offers two key advantages for portability. It creates a smaller overall footprint compared to a horizontal setup, making it easier to navigate through doorways and crowded spaces. This orientation also provides excellent gravitational stability.

Uncompromised Access

Even in a vertical setup, the split-tube design remains fully functional. The furnace can still be opened easily to place, inspect, or remove the process tube and samples, ensuring that portability does not hinder usability.

Understanding the Trade-offs

While highly effective, this solution comes with considerations that must be evaluated for your specific environment.

Reliance on Stand Quality

The safety and stability of the entire system depend on the build quality of the portable stand. Using a third-party or under-specified stand is a significant risk. The stand should always be sourced from or approved by the furnace manufacturer.

Potential for Vibration

While the stand provides a stable base, it is critical to ensure the floor surface is reasonably smooth. Moving the furnace over highly uneven surfaces or large gaps can still introduce shocks to the system.

Footprint of the Base

Although the vertical orientation saves space, the stand's base must be wide enough to ensure stability. You must account for the full footprint of the stand's legs, not just the furnace itself, in your facility planning.

Key Furnace Specifications Remain Critical

Opting for a portable model does not mean you have to compromise on core performance. These specifications are just as important in a mobile configuration.

Thermal Performance

Portable split tube furnaces are available with the same performance options as static models, including maximum temperatures of 1200°C, 1500°C, or 1800°C.

Process Capacity

Both single-zone and multi-zone configurations can be mounted on portable stands, allowing you to process single or multiple samples simultaneously as your application requires.

Physical Dimensions

Standard tube diameters (50, 80, 100, or 120 mm) and hot zone lengths (300 or 600 mm) are typically available. Custom dimensions can often be accommodated to fit your specific process needs.

Making the Right Choice for Your Goal

To select the correct portable furnace, evaluate it against your primary operational driver.

- If your primary focus is operational flexibility: Ensure you specify the manufacturer's integrated vertical furnace and heavy-duty portable stand system.

- If your primary focus is high-temperature processing: Confirm the portable model you choose can reach your required temperature and uses the appropriate heating elements (e.g., MoSi2 for 1800°C).

- If your primary focus is sample throughput: Verify that a multi-zone configuration is available in a portable format to meet your processing needs.

Ultimately, choosing the right configuration empowers your team with operational agility without sacrificing the performance and safety essential for your work.

Summary Table:

| Feature | Description |

|---|---|

| Configuration | Vertical split tube furnace on a heavy-duty portable stand |

| Mobility | Locking casters for easy movement and stability |

| Temperature Range | Up to 1800°C (e.g., 1200°C, 1500°C, 1800°C options) |

| Tube Diameters | Standard sizes: 50, 80, 100, 120 mm (custom available) |

| Hot Zone Lengths | 300 mm or 600 mm (customizable) |

| Zoning Options | Single-zone or multi-zone for sample throughput |

| Key Benefits | Enhanced safety, ergonomic design, uncompromised access |

Enhance your lab's flexibility and efficiency with KINTEK's advanced portable furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs precisely. Contact us today to discuss how our portable split tube furnaces can empower your team with safe, stable, and high-performance mobility!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab