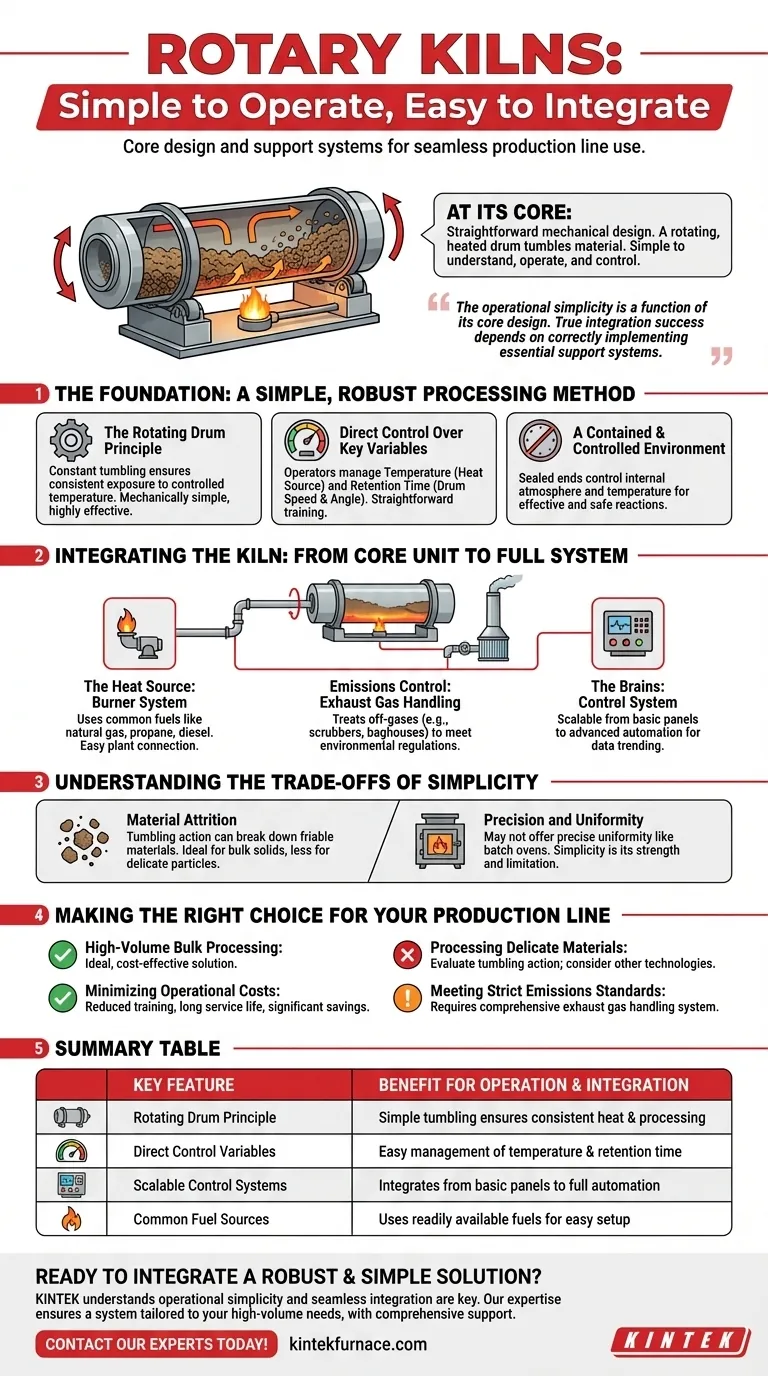

At its core, a rotary kiln's simplicity stems from its straightforward mechanical design: a rotating, heated drum that tumbles material. This fundamental mechanism is easy to understand, operate, and control, which directly facilitates its integration into a wide range of industrial production lines.

The operational simplicity of a rotary kiln is a function of its core design. However, true integration success depends on correctly implementing the essential support systems for heat generation, emissions control, and process automation.

The Foundation: A Simple, Robust Processing Method

The effectiveness of a rotary kiln lies in its direct and uncomplicated approach to material processing. This simplicity is not an accident but a result of its fundamental engineering.

The Rotating Drum Principle

A rotary kiln's primary function is to process materials by tumbling them within a heated, rotating cylinder. This constant motion ensures consistent exposure of the material to the controlled internal temperature.

This tumbling action is a mechanically simple yet highly effective way to achieve the desired chemical reaction or physical change.

Direct Control Over Key Variables

Operators primarily manage two key variables: temperature and retention time. The temperature is set by the heat source, and the retention time is controlled by the drum's rotational speed and angle.

Because these are the main levers for controlling the process, training operators and troubleshooting the system becomes significantly more straightforward compared to more complex thermal reactors.

A Contained and Controlled Environment

The rotating drum is sealed at both ends. These seals are crucial for controlling the internal atmosphere and temperature, which is essential for managing the process reactions effectively and safely.

Integrating the Kiln: From Core Unit to Full System

While the kiln itself is simple, it operates as the heart of a larger system. Understanding these support components is key to appreciating how it integrates into a production line.

The Heat Source: The Burner System

For direct-fired kilns, a burner provides the necessary process heat. These burners typically use common industrial fuels like natural gas, propane, or diesel, making them easy to source and connect to existing plant infrastructure.

The Emissions Control: Exhaust Gas Handling

A critical component for integration is the exhaust gas handling system. This system treats off-gases to meet environmental regulations before they are released.

Components can include quench towers, scrubbers, and baghouses. While this adds complexity, it's a modular system designed to handle the kiln's output, allowing the core operation to remain simple.

The Brains: The Control System

Control systems can range from basic panels for startup and shutdown to advanced automation for data trending and predictive maintenance. This scalability allows a plant to integrate a kiln at a level of complexity that matches its existing technical capabilities and budget.

Understanding the Trade-offs of Simplicity

The design that makes rotary kilns simple and robust also introduces specific limitations. Acknowledging these trade-offs is crucial for making an informed decision.

Material Attrition

The tumbling action that ensures good heat transfer can also cause attrition, breaking down friable or delicate materials. This makes kilns ideal for bulk solids but potentially unsuitable for materials where particle integrity is paramount.

Precision and Uniformity

While excellent for bulk processing, a rotary kiln may not offer the same level of precise temperature uniformity or gentle handling as more specialized equipment like a batch oven or fluidized bed reactor. The simplicity of the "tumble and heat" method is its strength and its limitation.

Making the Right Choice for Your Production Line

Your specific goal will determine if a rotary kiln's operational profile is the right fit for your needs.

- If your primary focus is high-volume bulk processing: The robust and straightforward design of a rotary kiln makes it an ideal, cost-effective solution.

- If your primary focus is minimizing operational costs: The reduced need for specialized operator training and the long service life of the equipment offer significant long-term savings.

- If your primary focus is processing delicate materials: You must carefully evaluate whether the tumbling action is acceptable or if a different thermal processing technology is required.

- If your primary focus is meeting strict emissions standards: Acknowledge that the simple kiln core will need to be paired with a comprehensive and potentially complex exhaust gas handling system.

Ultimately, the rotary kiln's operational simplicity makes it a powerful and reliable workhorse for the right application.

Summary Table:

| Key Feature | Benefit for Operation & Integration |

|---|---|

| Rotating Drum Principle | Simple tumbling action ensures consistent heat exposure and processing. |

| Direct Control Variables | Easy operator management of temperature and retention time. |

| Scalable Control Systems | Integrates with everything from basic panels to full automation. |

| Common Fuel Sources | Uses readily available fuels like natural gas for easy setup. |

Ready to integrate a robust and simple thermal processing solution into your production line?

At KINTEK, we understand that operational simplicity and seamless integration are key to your productivity. Our expertise in thermal processing technology ensures you get a rotary kiln system tailored to your specific high-volume needs, backed by comprehensive support for heat generation, emissions control, and automation.

Let's discuss how a KINTEK rotary kiln can enhance your efficiency and reliability. Contact our experts today for a customized solution!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems