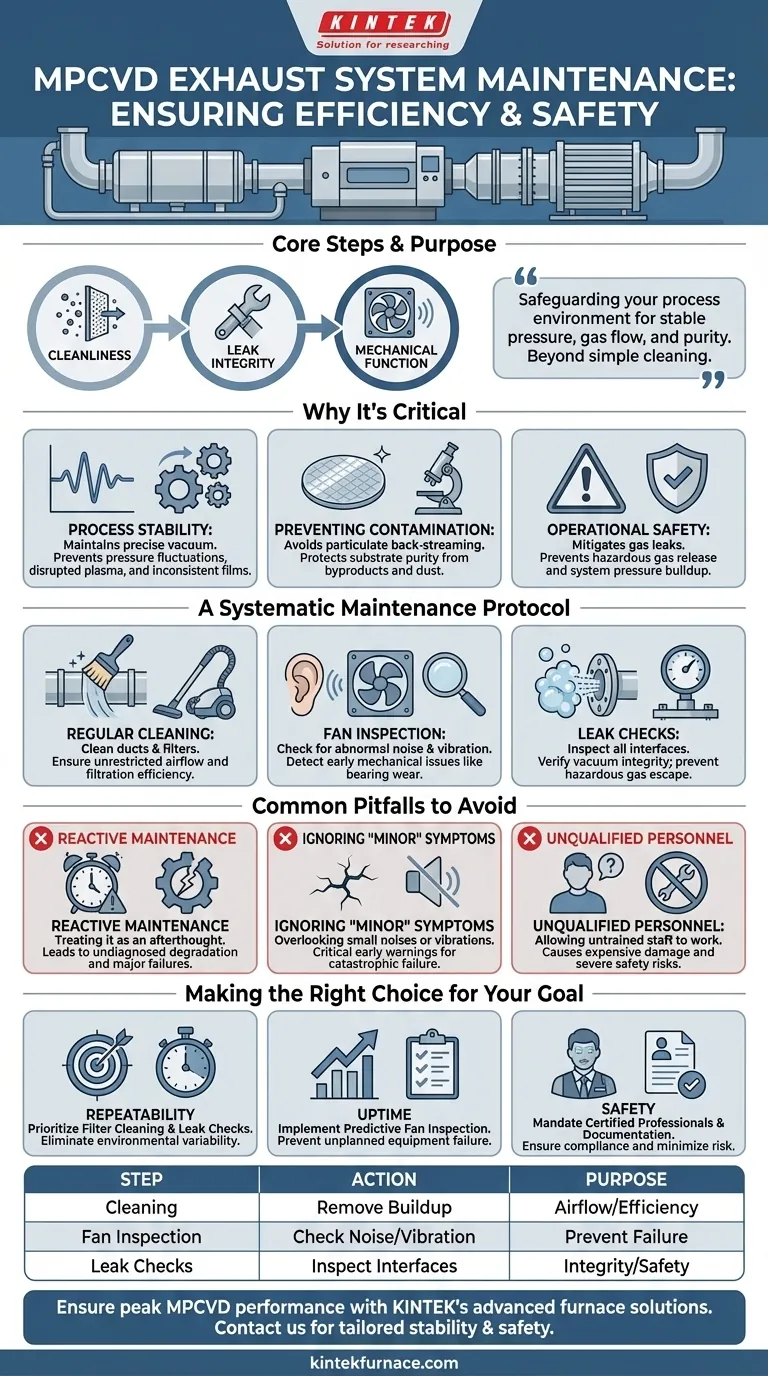

Effective maintenance of an MPCVD exhaust system is a multi-step process centered on cleanliness, leak integrity, and mechanical function. It requires regularly cleaning ducts and filters to remove particulate buildup, inspecting fans for abnormal noises or vibrations, and systematically checking all connection interfaces to ensure there are no leaks. These steps are fundamental to maintaining efficient and safe equipment operation.

The core purpose of exhaust system maintenance extends beyond simple cleaning. It is about safeguarding the integrity of your entire process environment, ensuring that pressure, gas flow, and purity remain stable to produce consistent, high-quality results while mitigating serious safety risks.

Why Exhaust Maintenance is Critical

The exhaust system is not a passive component; it actively regulates the deposition environment. Neglecting its maintenance directly impacts process outcomes and equipment longevity.

Maintaining Process Stability

A properly functioning exhaust system is essential for maintaining the precise vacuum levels required for MPCVD. Clogs, leaks, or inefficient fan performance can cause pressure fluctuations, disrupting plasma stability and leading to inconsistent film growth and quality.

Preventing Contamination

Process byproducts and dust can accumulate in exhaust ducts and filters. Without regular cleaning, these particulates can back-stream into the vacuum chamber, contaminating the substrate and compromising the purity of the deposited material.

Ensuring Operational Safety

Many gases used in MPCVD are hazardous. Leaks in the exhaust system can release these gases into the lab environment, creating a significant safety hazard for personnel. Furthermore, a clogged exhaust can lead to pressure buildup within the system, posing a risk to the equipment itself.

A Systematic Maintenance Protocol

A structured approach ensures that no critical checks are missed. This protocol should be part of a comprehensive equipment maintenance schedule.

Regular Cleaning of Ducts and Filters

Dust, dirt, and process residues must be cleaned from all exhaust ducts and filters. This action maintains unrestricted airflow and ensures the filtration system operates at peak efficiency, which is vital for both pressure control and environmental safety.

Fan Inspection for Noise and Vibration

The exhaust fan is the heart of the system. It should be checked regularly for any unusual noises or vibrations. These are often the first indicators of mechanical issues like bearing wear or imbalance, which can lead to sudden failure and costly downtime.

Leak Checks at All Interfaces

Every connection point, seal, and joint in the exhaust line is a potential point of failure. These interfaces must be inspected methodically for leaks to ensure the vacuum integrity of the system is not compromised and that no hazardous gases can escape.

Common Pitfalls to Avoid

Even with a protocol, certain oversights can undermine your maintenance efforts. Recognizing these common pitfalls is key to avoiding them.

Treating Maintenance as an Afterthought

Maintenance must be a scheduled, proactive activity. Deferring cleaning or inspections leads to gradual performance degradation that can be difficult to diagnose until a major failure occurs, affecting research timelines and production schedules.

Ignoring "Minor" Symptoms

Small vibrations or barely audible noises are not minor issues; they are critical early warnings. Addressing these symptoms immediately prevents catastrophic fan failures and avoids unplanned shutdowns.

Allowing Unqualified Personnel to Perform Work

MPCVD systems are complex and operate under hazardous conditions. Maintenance should only be performed by trained professionals who understand the equipment's principles and safety requirements. Improper handling can cause expensive damage and create severe safety risks.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your primary operational objective.

- If your primary focus is process repeatability: Prioritize meticulous filter cleaning and comprehensive leak checks to eliminate sources of environmental variability.

- If your primary focus is production uptime: Implement a strict, predictive schedule for fan inspection and bearing checks to prevent unplanned equipment failure.

- If your primary focus is operational safety: Mandate that all exhaust system work is performed by certified professionals and that every check is documented for compliance.

A disciplined approach to exhaust maintenance is a strategic investment in the consistency, safety, and longevity of your entire MPCVD operation.

Summary Table:

| Maintenance Step | Key Actions | Purpose |

|---|---|---|

| Regular Cleaning | Clean ducts and filters | Remove particulate buildup, ensure airflow and filtration efficiency |

| Fan Inspection | Check for noise and vibration | Detect mechanical issues early, prevent failure and downtime |

| Leak Checks | Inspect all connection interfaces | Maintain vacuum integrity, prevent gas leaks and safety hazards |

Ensure your MPCVD equipment operates at peak performance with KINTEK's advanced high-temperature furnace solutions. Our Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by deep customization capabilities, are designed to meet the unique needs of diverse laboratories. Contact us today to discuss how we can enhance your process stability and safety with reliable, tailored solutions!

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials

- What are the key design features of a CVD Tube Furnace? Optimize Your Material Synthesis with Precision

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films