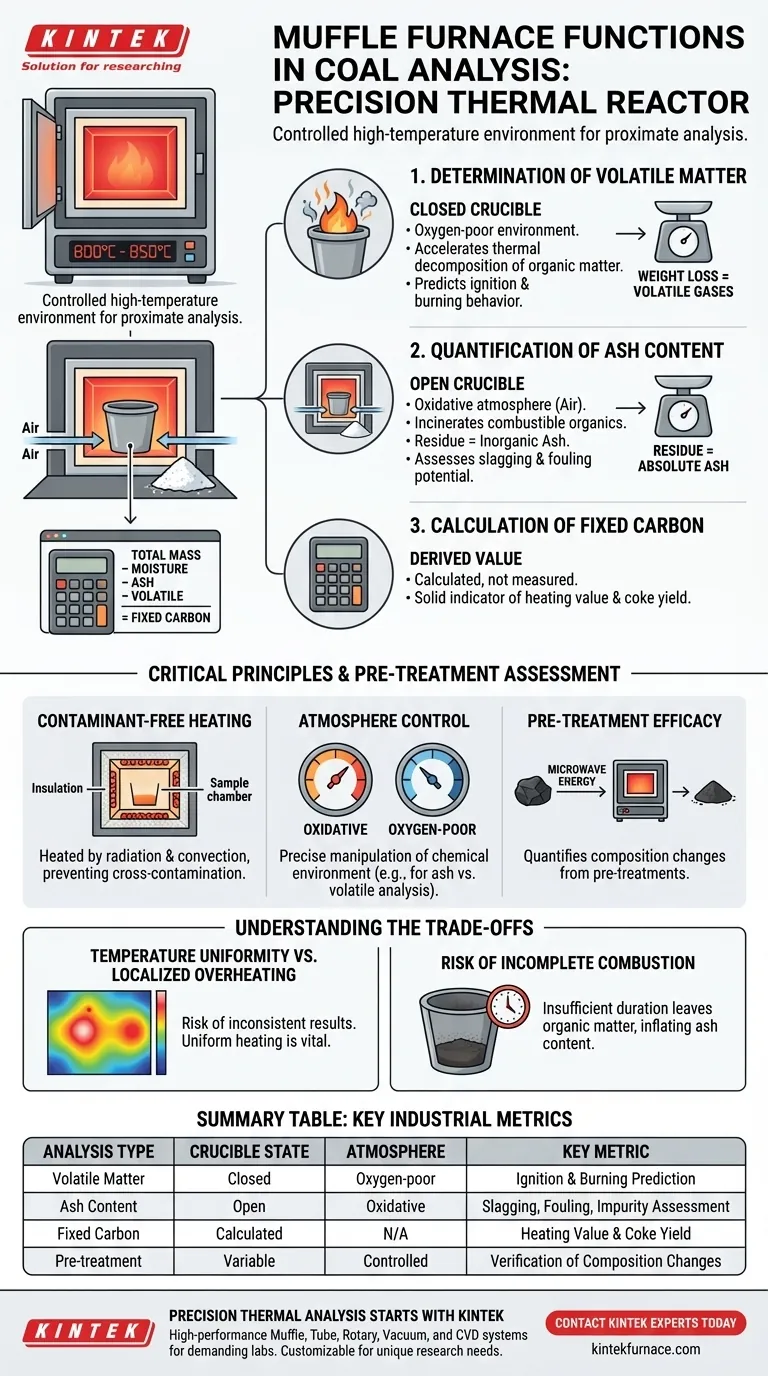

The muffle furnace functions as a precision thermal reactor designed to isolate and quantify the fundamental chemical components of coal. Its primary role is to provide a controlled, high-temperature environment—typically between 800°C and 850°C—to facilitate the thermal decomposition or complete combustion of coal samples for industrial analysis.

By subjecting samples to regulated heat in isolated crucibles, the muffle furnace drives off organic matter and volatiles. This process yields the essential data required to calculate volatile matter, fixed carbon, and ash content, which are the defining metrics of coal quality and combustion efficiency.

The Core Functions in Coal Analysis

The muffle furnace is the workhorse of proximate analysis, a standardized method used to determine the distribution of products obtained when a coal sample is heated under specified conditions.

Determination of Volatile Matter

To measure volatile content, the furnace heats the coal sample in a closed crucible (without exposure to air) at high temperatures.

This accelerates the thermal decomposition of the organic matter.

The weight loss recorded during this process represents the volatile gases released, which helps predict how the coal will ignite and burn in industrial boilers.

Quantification of Ash Content

Ash determination requires heating the sample in an open crucible to allow for oxidation.

The furnace acts as an incinerator, burning off all combustible organic materials until only the inorganic residue (absolute ash) remains.

This residue is critical for understanding the potential for slagging and fouling in furnace systems.

Calculation of Fixed Carbon

While not measured directly, fixed carbon is a calculated value derived from the data the furnace provides.

Once the moisture, ash, and volatile matter have been determined via furnace procedures, the remaining mass represents the fixed carbon.

This metric acts as a solid indicator of the coal's heating value and coke yield.

Assessment of Pre-treatment Efficacy

Modern industrial analysis often involves pre-treating coal, such as using microwave energy to alter its structure.

The muffle furnace is used to quantify how these pre-treatment modes change the coal's composition.

By comparing furnace results before and after treatment, analysts can verify improvements in combustion properties or impurity removal.

Critical Operational Principles

Contaminant-Free Heating

The term "muffle" refers to the insulation that separates the heating elements and combustion byproducts from the sample chamber.

This ensures that the coal is heated solely by radiation and convection, preventing cross-contamination from fuel gases or the heating source itself.

Precise Atmosphere Control

The furnace allows operators to manipulate the chemical environment surrounding the sample.

For ash determination, an oxidative atmosphere is maintained to ensure complete combustion.

Conversely, for volatile analysis, the environment within the crucible is kept oxygen-poor to ensure decomposition rather than burning.

Understanding the Trade-offs

While muffle furnaces are indispensable, accurate analysis requires navigating specific limitations and potential pitfalls.

Temperature Uniformity vs. Localized Overheating

High-efficiency heating elements are designed to reach target temperatures quickly, but they can create hot spots.

If the temperature distribution is not uniform, samples placed in different areas of the chamber may yield inconsistent results.

It is vital to use a furnace with an optimized heating system to ensure every crucible experiences the exact same thermal conditions.

The Risk of Incomplete Combustion

For ash analysis, simply reaching the target temperature of 800°C is not always sufficient if the duration is too short.

Incomplete oxidation leaves organic matter behind, artificially inflating the ash content reading.

Operators must visually verify that the residue is a clean, white/grey ash, indicating the total removal of carbonaceous material.

Making the Right Choice for Your Goal

The specific settings you employ on the muffle furnace should be dictated by the specific data point you are prioritizing.

- If your primary focus is Ash Content: Ensure the furnace has an ample air intake or exhaust to maintain an oxidative atmosphere, and verify the sample reaches "constant weight" to prove complete combustion.

- If your primary focus is Volatile Matter: Prioritize the seal of your crucibles and precise temperature ramping to prevent oxidation, which would skew the volatile reading.

- If your primary focus is Environmental Compliance: Use the furnace to convert samples to absolute ash, which allows for the subsequent chemical analysis of inorganic pollutants like sulfur or heavy metals.

Ultimately, the muffle furnace transforms raw coal into quantifiable data, serving as the definitive judge of fuel quality and process suitability.

Summary Table:

| Analysis Type | Crucible State | Atmosphere | Key Industrial Metric |

|---|---|---|---|

| Volatile Matter | Closed | Oxygen-poor | Ignition & burning behavior prediction |

| Ash Content | Open | Oxidative | Slagging, fouling, & impurity assessment |

| Fixed Carbon | Calculated | N/A | Solid indicator of heating value & coke yield |

| Pre-treatment | Variable | Controlled | Verification of composition changes/purity |

Precision Thermal Analysis Starts with KINTEK

Accurate coal characterization requires exceptional temperature uniformity and rigorous atmosphere control. Backed by expert R&D and elite manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding lab environments. Our high-temp furnaces are fully customizable to meet your unique research and industrial analysis needs.

Ready to enhance your lab’s efficiency and data accuracy? Contact KINTEK Experts Today to find the perfect thermal solution for your applications.

Visual Guide

References

- Lele Feng, Jiaxuan Sun. H2 production in underground coal gasification with pretreatment by non-focusing microwave. DOI: 10.3389/fchem.2025.1586267

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of muffle furnaces in heat treating metals? Achieve Clean, Controlled Metal Processing

- What is the core role of a laboratory muffle furnace in rice husk-based biochar? Master Your Pyrolysis Process

- What are the temperature capabilities of a lab muffle furnace? Find the Right Heat for Your Lab Needs

- How does the muffle furnace ensure uniform heating? Achieve Precise, Even Heat for Your Lab

- What are the main components of a box type resistance furnace? Unlock Precision Heating for Your Lab

- What are the core functions of muffle furnaces in steel testing? Simulate Cooling & Microstructure Evolution

- What are the main applications of muffle furnaces? Unlock Clean, High-Temp Processing for Your Lab

- What personal protective equipment (PPE) is recommended for benchtop furnace use? Ensure Lab Safety with Proper Gear