At its core, a muffle furnace is a high-temperature oven used for a wide range of analytical, scientific, and manufacturing processes. Its primary applications fall into three main categories: quantitative analysis like determining ash content, heat treatment to alter the properties of materials, and the high-temperature production of items like ceramics, glass, and enamel coatings.

The defining feature of a muffle furnace is not just its ability to reach high temperatures, but its design that isolates the material being heated from the fuel source and its combustion byproducts. This provides a clean, contaminant-free environment essential for both precise analysis and high-purity manufacturing.

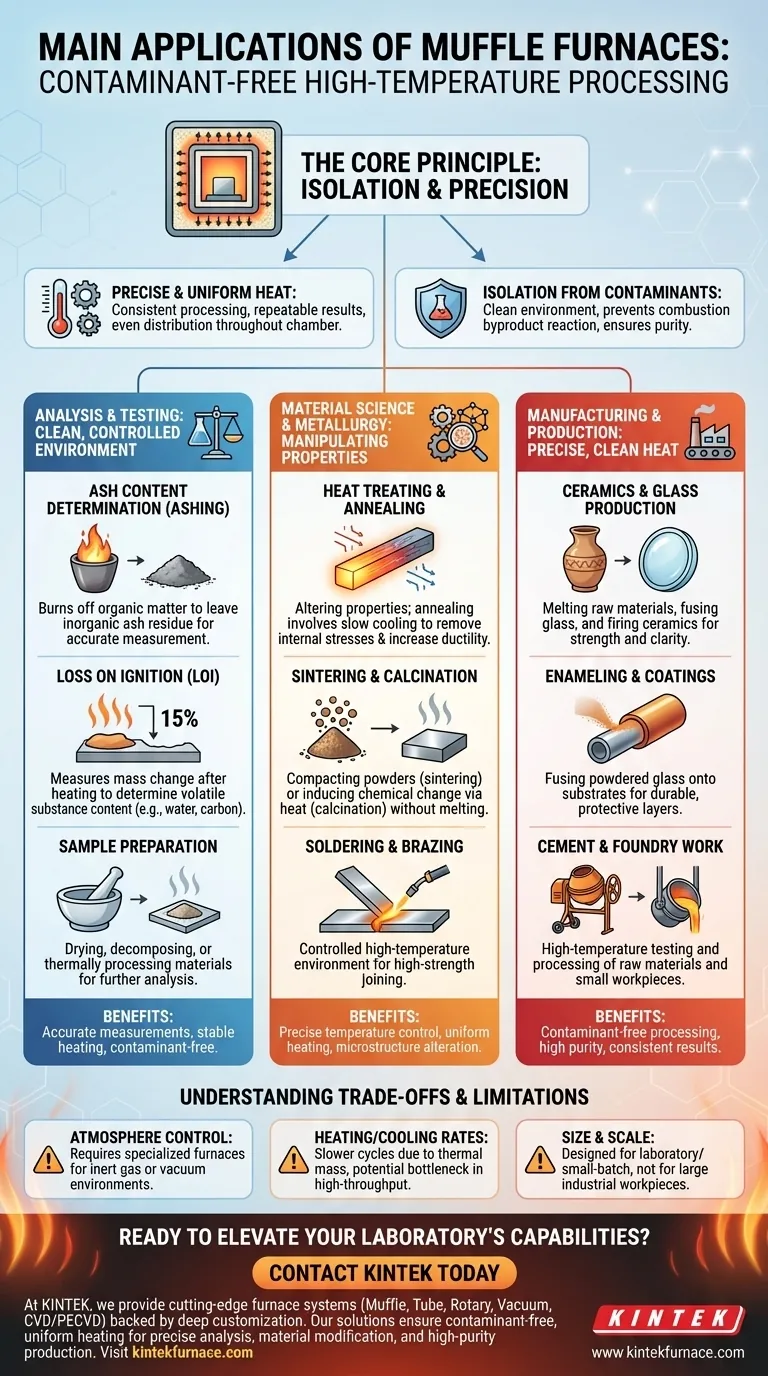

The Core Principle: Contaminant-Free High-Temperature Processing

To understand the applications of a muffle furnace, you must first understand its fundamental design advantage. The term "muffle" refers to the insulated inner chamber that separates the sample from the heating elements.

Precise and Uniform Heat

A muffle furnace is engineered to provide exceptionally uniform heat throughout its chamber. This, combined with precise temperature control, ensures that an entire sample or workpiece is processed evenly, leading to consistent and repeatable results.

Isolation from Contaminants

In direct-fired furnaces, byproducts of combustion can react with the material being heated. The muffle acts as a barrier, preventing this contamination. This is critical for processes where chemical purity is paramount, such as in analytical chemistry or technical ceramics production.

Key Applications in Analysis and Testing

The clean, controlled environment of a muffle furnace makes it an indispensable tool in analytical laboratories.

Ash Content Determination (Ashing)

This is one of the most common applications. A sample is heated to a high temperature to burn off all organic matter, leaving only the inorganic, non-combustible ash residue. The furnace provides the stable, high-temperature environment needed for complete combustion, allowing for accurate measurement of a material's ash content.

Loss on Ignition (LOI)

Closely related to ashing, LOI testing measures the change in a sample's mass after being heated to a specific temperature. This is used to determine the content of volatile substances, such as water or carbon, in materials like minerals, soil, or cement.

Sample Preparation for Chemical Analysis

Chemists and material scientists use muffle furnaces to prepare samples for further analysis. This can involve drying, decomposing, or thermally processing a material to make it suitable for other analytical techniques.

Applications in Material Science and Metallurgy

Muffle furnaces are vital for manipulating the microstructure and properties of metals, alloys, and other materials through carefully controlled heating and cooling cycles.

Heat Treating and Annealing

Heat treating is a broad term for processes that alter a material's physical and sometimes chemical properties. Annealing, a specific type of heat treatment, involves heating a material and allowing it to cool slowly to remove internal stresses and increase its ductility.

Sintering and Calcination

Sintering is the process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction. This is fundamental in powder metallurgy and ceramics. Calcination involves heating a solid to high temperatures to induce a chemical change, such as removing water or decomposing carbonates.

Soldering and Brazing

For high-strength joining of metals, muffle furnaces can provide the controlled, high-temperature environment needed for brazing and certain soldering applications, ensuring a clean and durable bond.

Applications in Manufacturing and Production

The ability to deliver precise, clean heat at high temperatures makes the muffle furnace a cornerstone in several manufacturing industries.

Ceramics and Glass Production

The furnace is central to creating technical ceramics and glass. It is used for melting raw materials, fusing glass components, and firing ceramics, where temperature uniformity and a lack of contaminants are critical for achieving the desired strength and clarity.

Enameling and Coatings

Creating enamel coatings involves fusing powdered glass onto a substrate, typically metal. A muffle furnace provides the clean, consistent heat required to melt the powder into a smooth, durable, and protective layer.

Cement and Foundry Work

In heavy industries like cement production and foundries, muffle furnaces are used for a variety of high-temperature testing and processing steps on raw materials and small workpieces.

Understanding the Trade-offs

While incredibly versatile, a muffle furnace is not the universal solution for all heating applications. It's important to recognize its limitations.

Atmosphere Control

A standard muffle furnace operates with an air atmosphere. For processes requiring an inert gas (like argon) or a vacuum to prevent oxidation, a more specialized and expensive furnace is required.

Heating and Cooling Rates

Compared to methods like induction heating, the thermal mass of a muffle furnace's insulation means that heating and cooling cycles are relatively slow. While this is an advantage for processes like annealing, it can be a bottleneck in high-throughput production.

Size and Scale

Muffle furnaces are typically designed for laboratory-scale or small-batch production. They are not suited for processing very large industrial workpieces, which require larger, purpose-built industrial ovens.

Making the Right Choice for Your Goal

To determine if a muffle furnace is the right tool, consider your primary objective.

- If your primary focus is quantitative analysis (ashing, LOI): The furnace's ability to provide a stable, clean environment for complete combustion and accurate weight measurements is its key advantage.

- If your primary focus is modifying material properties (heat treating, annealing): The furnace's precise temperature control and uniform heating are essential for achieving the desired microstructure and physical characteristics.

- If your primary focus is high-purity manufacturing (technical ceramics, glass): The muffle's isolation from contaminants is non-negotiable for producing a final product without discoloration or structural defects.

Ultimately, the muffle furnace is a foundational tool for any process that demands clean, uniform, and precisely controlled high temperatures.

Summary Table:

| Application Category | Key Uses | Primary Benefits |

|---|---|---|

| Analysis & Testing | Ash content determination, Loss on ignition, Sample preparation | Clean environment, Accurate measurements, Stable heating |

| Material Science & Metallurgy | Heat treating, Annealing, Sintering, Calcination | Precise temperature control, Uniform heating, Microstructure alteration |

| Manufacturing & Production | Ceramics/glass production, Enameling, Cement/foundry work | Contaminant-free processing, High purity, Consistent results |

Ready to elevate your laboratory's capabilities with advanced high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse labs with cutting-edge furnace systems. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Whether you're focused on precise analysis, material modification, or high-purity production, our solutions ensure contaminant-free, uniform heating for reliable outcomes. Contact us today to discuss how we can tailor a furnace to your specific requirements and boost your efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis