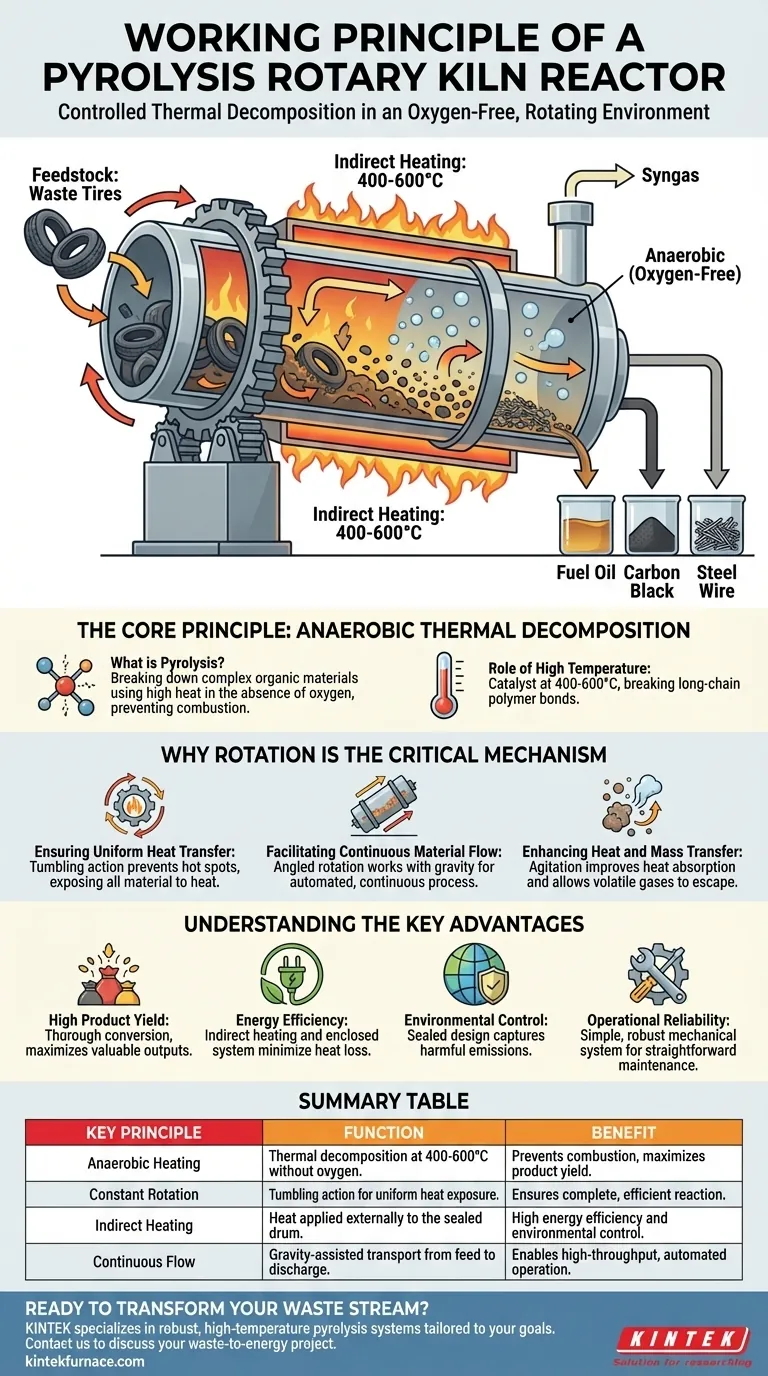

The working principle of a pyrolysis rotary kiln reactor is the controlled thermal decomposition of materials in an oxygen-free environment, driven by constant rotation. The kiln, a large rotating drum, heats feedstock like waste tires to between 400-600°C. This combination of heat and tumbling motion breaks the material down into valuable outputs like fuel oil, carbon black, and steel wire.

The core concept is not merely heating the material, but using continuous rotation to guarantee every particle receives uniform heat exposure. This mechanical action is the key to achieving efficient, complete, and consistent thermal decomposition.

The Core Principle: Anaerobic Thermal Decomposition

What is Pyrolysis?

Pyrolysis is a chemical process that breaks down complex organic materials using high heat in the absence of oxygen.

By preventing combustion, this anaerobic (oxygen-free) environment ensures the material decomposes into its constituent components rather than simply burning away.

The Role of High Temperature

The reactor operates at high temperatures, typically 400°C to 600°C, which acts as the catalyst for the reaction.

This intense heat provides the energy needed to break the long-chain polymer bonds in materials like tires, releasing volatile gases and leaving behind solid residues.

Why Rotation is the Critical Mechanism

A static oven would heat waste unevenly, leading to an inefficient and incomplete reaction. The rotation of the kiln is the engineered solution that overcomes this fundamental problem.

Ensuring Uniform Heat Transfer

The constant, slow rotation of the kiln creates a tumbling action within the material bed.

This movement continuously exposes new surfaces to the heat source, preventing hot spots and ensuring that the entire volume of feedstock reaches the optimal pyrolysis temperature. Think of it like roasting coffee beans; the rotation is essential for an even result.

Facilitating Continuous Material Flow

The kiln is typically set at a slight angle. The rotational motion works with gravity to transport the material from the loading end to the discharge end.

This automated movement prevents blockages and allows for a continuous, rather than batch-fed, operational process, increasing overall throughput.

Enhancing Heat and Mass Transfer

The tumbling motion also thoroughly mixes the solid material. This agitation improves the efficiency of heat transfer into the core of the material.

Simultaneously, it helps the volatile gases escape from the solid bed more easily, where they can be collected and processed.

Understanding the Key Advantages

The unique working principle of the rotary kiln directly leads to several operational advantages. Understanding these benefits is key to recognizing why this design is so effective.

High Product Yield

Because of the uniform heating and efficient mixing, the pyrolysis process is incredibly thorough. This maximizes the conversion of waste into valuable products and minimizes unreacted residue.

Energy Efficiency

Most rotary kilns use an indirect heating method, where the exterior of the drum is heated and that heat is transferred to the material inside.

The enclosed nature of the system minimizes heat loss to the surrounding environment, resulting in lower overall energy consumption compared to many direct-heating designs.

Environmental Control

The sealed, anaerobic design is critical for emissions control. It prevents harmful gases from escaping into the atmosphere during the decomposition process.

Operational Reliability

The mechanical system, while large, is fundamentally simple and robust. This leads to greater reliability and makes maintenance more straightforward compared to more complex reactor designs.

Making the Right Choice for Your Goal

When evaluating this technology, connect its core principles to your primary objectives.

- If your primary focus is maximizing product quality and yield: The uniform heating achieved through controlled rotation is the most important feature, as it ensures a complete and consistent chemical reaction.

- If your primary focus is operational efficiency: The continuous material transport and high thermal efficiency of the enclosed rotating drum are key to achieving high throughput with minimal energy input.

- If your primary focus is environmental compliance: The sealed, oxygen-free system is the fundamental design choice that ensures emissions are contained and managed effectively.

Ultimately, the pyrolysis rotary kiln's elegant design transforms a simple principle—even heating—into a powerful tool for converting waste into valuable resources.

Summary Table:

| Key Principle | Function | Benefit |

|---|---|---|

| Anaerobic Heating | Thermal decomposition at 400-600°C without oxygen. | Prevents combustion, maximizes product yield. |

| Constant Rotation | Tumbling action for uniform heat exposure. | Ensures complete, efficient reaction. |

| Indirect Heating | Heat applied externally to the sealed drum. | High energy efficiency and environmental control. |

| Continuous Flow | Gravity-assisted transport from feed to discharge. | Enables high-throughput, automated operation. |

Ready to transform your waste stream into valuable products?

The controlled, efficient thermal decomposition process of a rotary kiln reactor is key to maximizing your return on investment. At KINTEK, we specialize in designing and manufacturing robust, high-temperature pyrolysis systems tailored to your specific feedstock and output goals.

Our expert R&D and manufacturing team can provide you with a solution that delivers:

- Maximized Yield: Uniform heating ensures complete conversion of materials like tires or biomass into fuel oil, carbon black, and syngas.

- Operational Efficiency: Continuous processing design for high throughput with minimal energy loss.

- Environmental Compliance: Sealed, oxygen-free operation for safe and controlled emissions.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs.

Contact us today to discuss how a KINTEK pyrolysis rotary kiln reactor can power your waste-to-energy project.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do pyrolysis rotary kiln reactors function? Unlock Efficient Waste-to-Value Conversion

- Why is an industrial-grade rotary reactor necessary in the oil sludge pyrolysis process? Maximize Yield & Efficiency

- Why must precise temperature measurement and upper-limit control be implemented during the rotary furnace melting of ductile iron?

- What technical requirements are placed on heating equipment for fast pyrolysis? Master High-Yield Bio-Oil Production

- What is the role of indirect-fired rotary kilns in energy production? Unlock Sustainable Waste-to-Energy Solutions