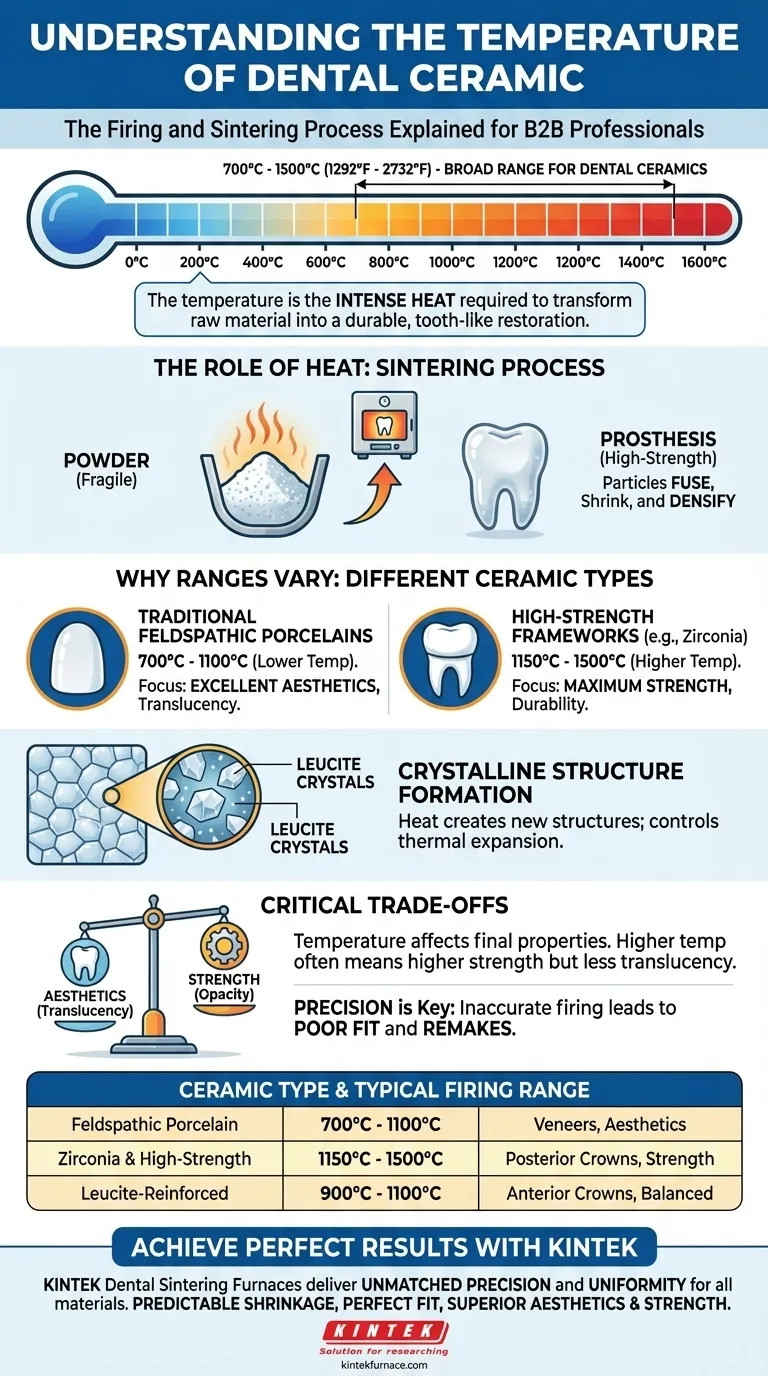

The "temperature" of a dental ceramic refers to its firing or sintering temperature, the intense heat required to transform raw material into a durable, tooth-like restoration. This process typically occurs in a dental furnace within a broad range of 700°C to 1500°C (1292°F to 2732°F), with the precise temperature dictated by the specific type of ceramic being used.

The firing temperature of a dental ceramic is not a single value but a critical processing variable that changes based on the material's composition. This temperature is precisely controlled to trigger a physical transformation, densifying the material and determining its final strength, fit, and aesthetics.

The Role of Heat in Creating Dental Ceramics

The temperature applied in a dental furnace is the fundamental catalyst that converts a fragile powder or chalky block into a high-strength dental prosthesis. This process is known as sintering or firing.

From Powder to Prosthesis: The Sintering Process

Sintering is the process of compacting and forming a solid mass of material by heat, without melting it to the point of liquefaction.

During firing, the individual ceramic particles fuse at their contact points. This fusion reduces the empty spaces between particles, causing the material to shrink and become significantly more dense and strong.

Why Temperature Ranges Vary So Widely

Different types of dental ceramics have vastly different chemical makeups, which require unique temperature "recipes" for proper firing.

For example, traditional feldspathic porcelains are often fired at lower temperatures, typically between 700°C and 1100°C. These materials are known for their excellent aesthetics.

In contrast, high-strength framework ceramics can require much higher temperatures. For instance, some older feldspathic materials used to form specific crystal structures required heating between 1150°C and 1500°C. Modern zirconia, a dominant material, is sintered at similarly high temperatures.

The Formation of Crystalline Structures

The heat does more than just fuse particles; it can also create new crystalline structures within the ceramic's glassy matrix.

In some feldspathic ceramics, heating causes the formation of leucite crystals. This is significant because leucite has a different coefficient of thermal expansion (how much it expands and contracts with heat) than the surrounding glass.

Controlling the formation of these crystals is essential for managing the final properties of the restoration, especially when layering ceramic onto a metal or zirconia substructure. A mismatch in thermal expansion will cause cracks and failure.

Understanding the Critical Trade-offs

The choice of firing temperature is directly linked to a series of trade-offs between the final properties of the restoration. Understanding these is key to material selection and processing.

Temperature Control and Dimensional Accuracy

The sintering process inherently involves shrinkage. If the temperature is not controlled with extreme precision according to the manufacturer's protocol, this shrinkage can become unpredictable.

Inaccurate firing can lead to a crown or bridge that is too small or distorted, resulting in a poor fit that must be remade. This is a primary concern for every dental laboratory technician.

Aesthetics vs. Strength

Generally, there is an inverse relationship between a ceramic's translucency and its strength, which is often tied to its processing temperature.

Lower-temperature glass-ceramics and feldspathic porcelains are often more translucent and life-like, making them ideal for veneers. Higher-temperature sintering ceramics like zirconia are incredibly strong and opaque, making them the standard for posterior crowns and bridges that endure heavy biting forces.

Making the Right Choice for Your Goal

The ideal "temperature" is determined entirely by the material you have chosen to meet a specific clinical need. The material dictates the process.

- If your primary focus is maximum aesthetics (e.g., anterior veneers): You will likely use a lower-firing temperature glass-ceramic or feldspathic porcelain to achieve optimal translucency.

- If your primary focus is maximum strength (e.g., a posterior bridge): You will use a high-strength ceramic like zirconia, which requires a much higher sintering temperature.

- If you are layering porcelain onto a core (PFM or PFZ): You must use materials with compatible thermal expansion coefficients and follow a precise multi-stage firing schedule to ensure a strong bond without cracking.

Ultimately, understanding a ceramic's required temperature is to understand the very nature of the material itself.

Summary Table:

| Ceramic Type | Typical Firing Range | Primary Use Case | Key Characteristic |

|---|---|---|---|

| Feldspathic Porcelain | 700°C - 1100°C | Veneers, Aesthetic Layering | High Translucency, Excellent Aesthetics |

| Zirconia & High-Strength Frameworks | 1150°C - 1500°C | Posterior Crowns, Bridges | Maximum Strength, Durability |

| Leucite-Reinforced Glass-Ceramics | 900°C - 1100°C | Anterior Crowns, Inlays/Onlays | Balanced Strength & Aesthetics |

Achieve Perfect Firing Results with KINTEK Dental Furnaces

Precise temperature control is non-negotiable for creating durable, accurately-fitting dental restorations. KINTEK understands the critical demands of dental laboratories. Our advanced Dental Sintering Furnaces are engineered to deliver the exceptional temperature uniformity and precise ramp rates required for consistent results with all ceramic materials—from feldspathic porcelain to high-strength zirconia.

Why Choose KINTEK for Your Dental Furnace Needs?

- Unmatched Precision: Ensure predictable shrinkage and perfect fit for every crown, bridge, and veneer.

- Superior Aesthetics & Strength: Achieve the ideal material properties by maintaining exact firing schedules.

- Enhanced Productivity: Reliable performance and intuitive controls streamline your workflow.

Ready to elevate the quality and consistency of your dental ceramics? Our experts are ready to help you select the perfect furnace for your laboratory's specific materials and workflow.

Contact KINTEK today for a personalized consultation and discover the difference precision engineering makes.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations