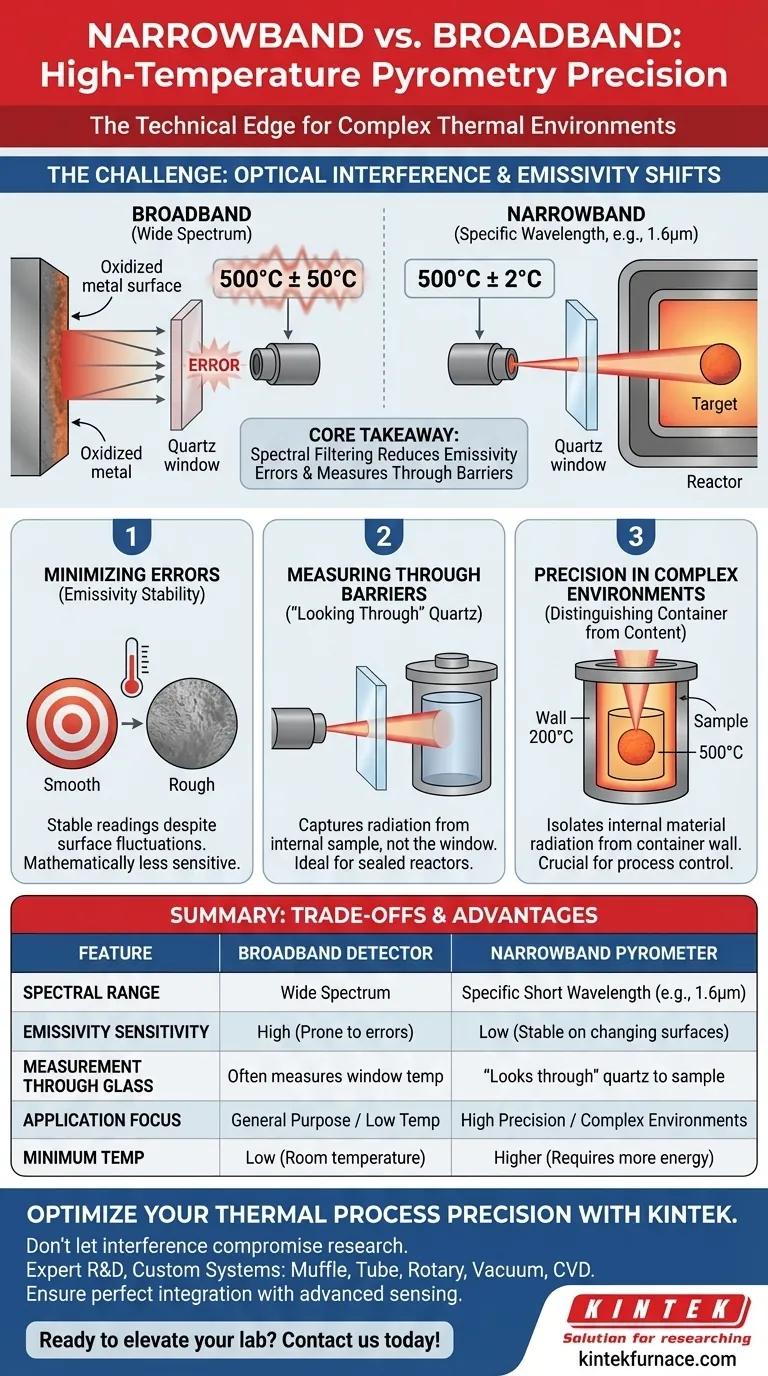

Narrowband infrared pyrometers offer superior precision in complex thermal environments by filtering out optical interference. Unlike broadband detectors that capture a wide spectrum of radiation, narrowband devices operate at specific short wavelengths (such as 1.6 micrometers). This selectivity minimizes errors caused by fluctuating surface conditions and allows the device to measure specific internal targets through intervening materials like quartz windows.

Core Takeaway By restricting measurement to specific short wavelengths, narrowband pyrometers significantly reduce measurement errors caused by emissivity changes. This "spectral filtering" capability enables precise temperature control of internal samples inside closed vessels, distinct from the container walls.

Minimizing Measurement Errors

Reducing Sensitivity to Emissivity Changes

Broadband detectors are highly susceptible to errors when a target's surface properties change. If a material oxidizes or changes texture during heating, its emissivity shifts, skewing the temperature reading.

A narrowband pyrometer operating at short wavelengths (like 1.6 micrometers) is mathematically less sensitive to these shifts. It provides stable, accurate data even when the target material's surface condition fluctuates significantly during the process.

Measuring Through Barriers

The Capability to "Look Through" Quartz

In many industrial applications, the target material is sealed inside a reaction chamber or a vacuum vessel. Broadband detectors often fail here because standard window materials (like glass or quartz) are opaque to long-wavelength infrared, causing the sensor to measure the window temperature rather than the sample.

Narrowband pyrometers tuned to specific spectral regions are designed to pass through these materials. By operating at 1.6 micrometers, the sensor "looks through" a quartz window as if it were transparent, capturing radiation directly from the internal sample.

Precision in Complex Environments

Distinguishing Container from Content

In advanced applications, such as microwave thermal processing, thermal gradients can be extreme. The container wall holding a sample may be significantly cooler or hotter than the material inside.

Narrowband technology allows you to isolate the radiation from the internal material while ignoring the container. This distinction is critical for process control, ensuring you are regulating the chemistry of the sample rather than the temperature of the vessel holding it.

Understanding the Trade-offs

Minimum Temperature Requirements

While short-wavelength sensors offer higher accuracy, they require sufficient energy to function. This means they often have a higher minimum temperature range compared to broadband detectors. They are generally unsuited for measuring objects at room temperature.

Specificity vs. Versatility

Broadband detectors are general-purpose tools that work reasonably well across many standard applications. Narrowband pyrometers are specialized instruments; they must be matched to the specific window material and temperature range of your unique process to provide value.

Making the Right Choice for Your Goal

To determine if a narrowband pyrometer is the correct solution for your application, consider your specific constraints:

- If your primary focus is measuring inside a sealed reactor: Choose a narrowband pyrometer tuned to a wavelength transparent to your viewport (e.g., quartz) to measure the internal sample directly.

- If your primary focus is stability on changing surfaces: Opt for short-wavelength narrowband sensors to mitigate errors caused by oxidation or fluctuating emissivity.

- If your primary focus is separating layer temperatures: Use narrowband technology to distinguish between a container wall and the material inside, particularly in microwave processing.

True precision in non-contact thermometry comes from selecting the wavelength that sees your target, not the obstacles surrounding it.

Summary Table:

| Feature | Broadband Detector | Narrowband Pyrometer |

|---|---|---|

| Spectral Range | Wide Spectrum | Specific Short Wavelength (e.g., 1.6µm) |

| Emissivity Sensitivity | High (Prone to errors) | Low (Stable on changing surfaces) |

| Measurement Through Glass | Often measures window temp | "Looks through" quartz to sample |

| Application Focus | General Purpose / Low Temp | High Precision / Complex Environments |

| Minimum Temp | Low (Room temperature) | Higher (Requires more thermal energy) |

Optimize Your Thermal Process Precision with KINTEK

Don't let optical interference or emissivity shifts compromise your research. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique high-temperature needs. Our expert team ensures your thermal equipment integrates perfectly with advanced sensing technologies like narrowband pyrometers to provide the accuracy your materials demand.

Ready to elevate your lab's capabilities? Contact us today to discuss your custom furnace solution!

Visual Guide

References

- Gloria Cosoli, Gian Marco Revel. A Measurement Approach for Characterizing Temperature-Related Emissivity Variability in High-Emissivity Materials. DOI: 10.3390/s25020487

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is a high-vacuum system required for sealing quartz tubes? Achieve Ultra-Pure Chalcogenide Alloy Synthesis

- What process challenges are addressed by vacuum filtration equipment during the construction of CsPbBr3@CA-SiO2 films?

- What is the role of a BN crucible in Ca0.5Sr0.5AlSiN3:Eu2+ synthesis? Achieve High-Purity Nitride Phosphors

- What function do high-strength graphite molds serve? Essential Roles in Ti-6Al-4V Vacuum Hot Pressing

- Why is a BN coating used in Mg3Sb2 melting? Essential Purity and Protection Guide

- Why is a glassy carbon boat preferred over an alumina crucible for Na3Cu4Se4? Ensuring Phase Purity in Flux Synthesis

- What are the reasons for using high-purity alumina material for the reaction tubes in a Drop Tube Furnace? - Guide

- Why is a vacuum drying oven essential for Pd-Ni/ZrO2 catalyst preparation? Ensure Uniform Metal Distribution