The technical value of a high-vacuum high-temperature annealing furnace lies in isolation. It creates a controlled environment with extremely low oxygen partial pressure, allowing you to evaluate the CrSiN-Y coating's intrinsic properties without external interference. This precision enables the isolation of phase stability and grain structure changes caused solely by thermal stress, separating them from the effects of environmental oxidation or contamination.

Core Takeaway: This equipment is essential because it allows for the simulation of microstructural evolution in a pristine environment. It objectively validates whether specific Yttrium concentrations effectively inhibit grain coarsening and phase decomposition, providing a baseline of thermal stability before real-world oxidative factors are introduced.

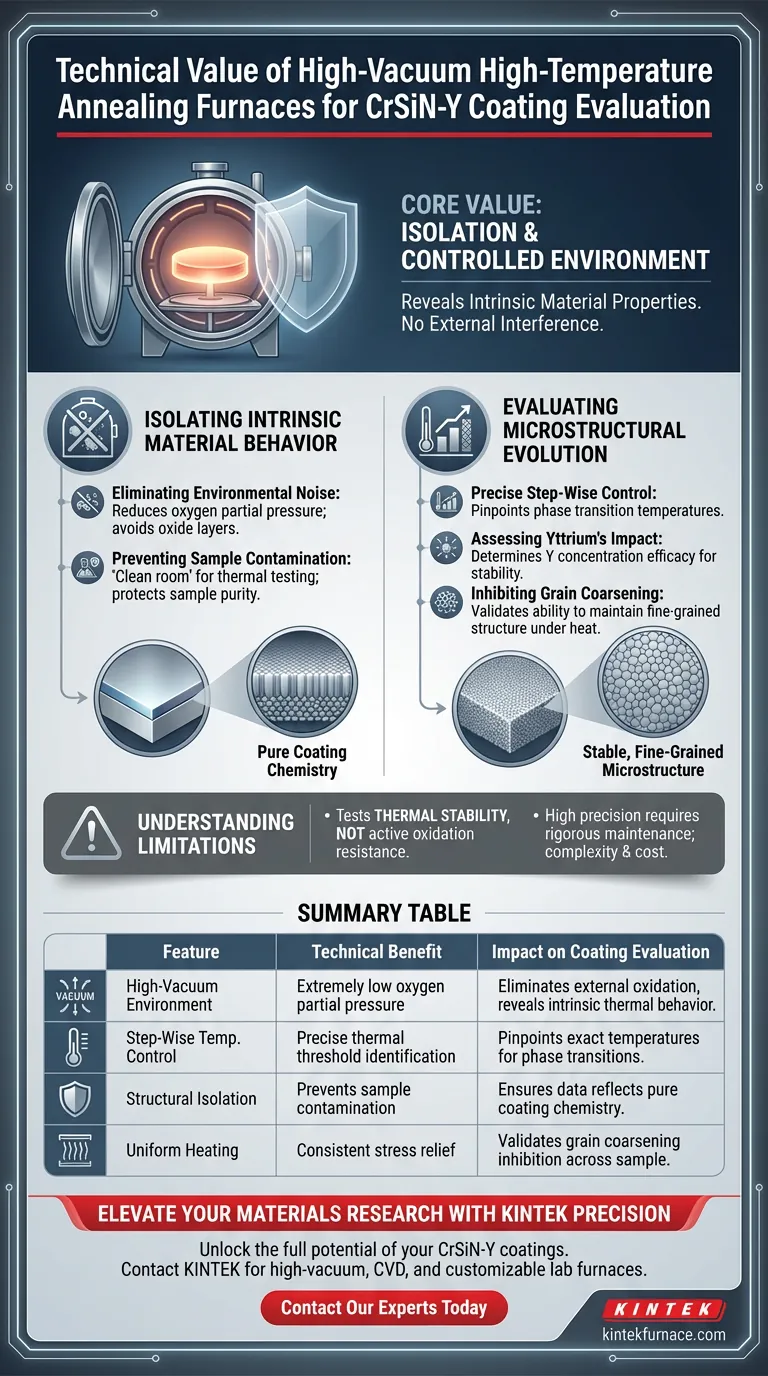

Isolating Intrinsic Material Behavior

To understand the true capabilities of a CrSiN-Y coating, you must first eliminate variables. The high-vacuum furnace serves as a "clean room" for thermal testing.

Eliminating Environmental Noise

In standard atmospheric furnaces, oxygen reacts with the sample surface, creating oxide layers that can obscure the material's internal structural changes.

By utilizing a high-vacuum environment, you drastically reduce oxygen partial pressure. This ensures that any degradation observed is a result of the material's internal thermodynamics, not external attack.

Preventing Sample Contamination

Evaluating advanced coatings requires absolute purity.

This process protects the sample from external environmental contamination. It guarantees that the data collected reflects the coating's chemistry and nothing else.

Evaluating Microstructural Evolution

The primary reference highlights that this equipment is not just about heating; it is about observing evolution under stress.

Precise Step-Wise Control

The furnace allows for precise, step-wise temperature control.

This capability is critical for identifying the exact thermal thresholds where the coating changes. You can pinpoint the specific temperature at which phase transitions occur.

Assessing the Impact of Yttrium

A key objective of this evaluation is determining the efficacy of Yttrium (Y) additives.

The controlled thermal environment reveals how different Yttrium concentrations influence phase stability. It provides the evidence needed to confirm if the additive is successfully stabilizing the material structure.

Inhibiting Grain Coarsening

Under high heat, material grains naturally tend to grow (coarsen), which typically reduces hardness and performance.

This testing method validates the coating's ability to inhibit this grain coarsening. It proves whether the microstructure remains stable and fine-grained under thermal load.

Uniform Stress Relief

As noted in supplementary contexts regarding metal processing, vacuum annealing provides superior heating uniformity.

This uniform heat distribution helps eliminate internal processing stresses. It ensures that the evaluation of the coating's ductility and mechanical limits is consistent across the entire sample geometry.

Understanding the Limitations

While this method is powerful, it is vital to recognize what it does not do to maintain an objective perspective.

Thermal Stability vs. Oxidation Resistance

This process tests thermal stability, not active oxidation resistance.

Because the vacuum removes oxygen, you are not testing how the coating interacts with air at high temperatures. You are testing how the coating holds itself together under heat.

The Cost of Precision

High-vacuum systems add complexity and cost to the testing regimen compared to standard air annealing.

They require rigorous maintenance to ensure the vacuum integrity is not compromised, as even a small leak can invalidate the "contamination-free" premise of the experiment.

Making the Right Choice for Your Goal

This equipment is a specialized tool for fundamental material characterization. Use the following guide to determine when to deploy it.

- If your primary focus is Material Formulation: Use this furnace to determine the optimal Yttrium concentration that maximizes phase stability prior to field testing.

- If your primary focus is Failure Analysis: Use this method to distinguish between failures caused by internal phase decomposition versus those caused by external oxidative corrosion.

This approach transforms the furnace from a simple heater into a critical validation tool for the fundamental physics of your coating.

Summary Table:

| Feature | Technical Benefit | Impact on Coating Evaluation |

|---|---|---|

| High-Vacuum Environment | Extremely low oxygen partial pressure | Eliminates external oxidation to reveal intrinsic thermal behavior. |

| Step-Wise Temperature Control | Precise thermal threshold identification | Pinpoints exact temperatures where phase transitions and decomposition occur. |

| Structural Isolation | Prevents sample contamination | Ensures data reflects pure coating chemistry without environmental noise. |

| Uniform Heating | Consistent stress relief | Validates the coating's ability to inhibit grain coarsening across the sample. |

Elevate Your Materials Research with KINTEK Precision

Unlock the full potential of your CrSiN-Y coatings by isolating intrinsic properties with our industry-leading high-temperature systems. Backed by expert R&D and precision manufacturing, KINTEK offers high-vacuum, CVD, and customizable lab furnaces designed to meet the rigorous demands of advanced material science.

Whether you need to validate phase stability or inhibit grain coarsening, our specialized equipment provides the pristine thermal environment required for accurate characterization. Contact our experts today to discuss how our customizable Muffle, Tube, and Vacuum systems can optimize your testing workflow.

Visual Guide

References

- Lishan Dong, Zhifeng Wang. Porous High-Entropy Oxide Anode Materials for Li-Ion Batteries: Preparation, Characterization, and Applications. DOI: 10.3390/ma17071542

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of using industrial vacuum furnaces for 3003mod aluminum? Optimize H14 Temper & Material Stress

- How does vacuum heat treating affect the grain structure of metal alloys? Achieve Precise Microstructure Control

- What are the challenges of maintaining a high vacuum in furnaces? Overcome Key Hurdles for Optimal Performance

- What components make up the vacuum system of a vacuum furnace? Unlock Precision for High-Temperature Processing

- What ceramic materials can be processed in vacuum heat treatment furnaces? Unlock High-Purity Processing for Advanced Ceramics

- What is the function of a high-vacuum furnace in tantalum carburization? Purity & Reaction Precision

- What is the role of a high-precision vacuum drying oven in biochar activation? Unlock Superior Surface Area

- What are the key features of vacuum furnaces? Achieve Absolute Control for High-Performance Materials