In short, vacuum heat treating creates the ideal environment for controlling grain structure. By removing atmospheric gases, it prevents unwanted chemical reactions like oxidation, ensuring that the thermal cycle of heating and cooling is the sole factor determining the metal's final properties. This allows for unparalleled precision in achieving the desired grain size and phase distribution for a specific alloy.

The primary value of vacuum heat treating is not that it creates one specific type of grain structure, but that it provides a pristine, unreactive environment. This guarantees that the intended metallurgical transformation—whether for hardening, annealing, or stress relieving—occurs with maximum uniformity and without surface degradation.

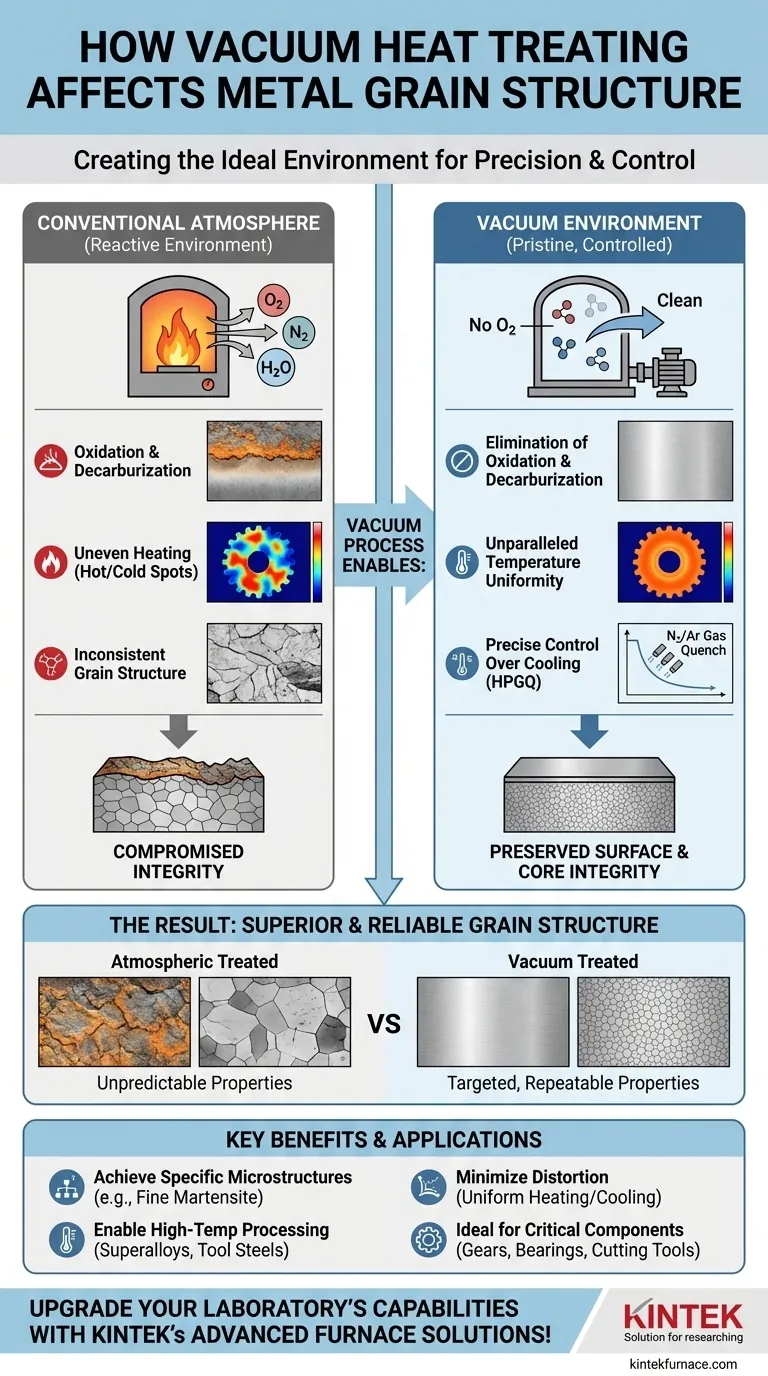

The Role of the Vacuum Environment

To understand the effect on grain structure, you must first understand what a vacuum furnace actually does. It's less about what it adds and more about what it removes: reactive gases, primarily oxygen.

Elimination of Oxidation and Decarburization

Atmospheric furnaces, even those with controlled gas mixtures, always contain some level of oxygen. At high temperatures, oxygen aggressively reacts with a metal's surface, forming a brittle layer of scale.

For steels, this environment can also lead to decarburization, where carbon atoms migrate out of the surface. This creates a soft, weak outer layer, compromising the component's wear resistance and fatigue life, regardless of the core grain structure. A vacuum physically removes the oxygen, completely preventing these destructive reactions.

Unparalleled Temperature Uniformity

Heating in a vacuum primarily occurs through radiation. This method promotes exceptionally uniform temperature across the entire workpiece, eliminating the hot and cold spots common in conventional convection furnaces.

Consistent temperature ensures that the entire part—from the thin sections to the thick core—undergoes its phase transformation at the same time. This results in a homogenous grain structure, which is critical for predictable mechanical performance.

Precise Control Over Cooling

After heating, the cooling rate (quenching) is arguably the most critical factor in determining the final grain structure, especially for hardening. Vacuum furnaces utilize high-pressure gas quenching (HPGQ) using inert gases like nitrogen or argon.

This process allows for rapid, highly controlled cooling that can be precisely tailored to the alloy's requirements. It provides the fast cooling needed to form a fine-grained martensitic structure for high strength, but without the thermal shock and distortion risk associated with liquid quenching (oil or water).

How This Translates to Grain Structure

The clean, controlled environment of a vacuum furnace directly enables the formation of a superior and more reliable grain structure.

Achieving Target Microstructures with Precision

The goal of heat treatment is to produce a specific microstructure, such as fine-grained martensite for toughness or a coarse grain structure for high-temperature creep resistance.

Because the vacuum environment is so pure, the results are highly repeatable and predictable. The grain structure you achieve is the one dictated by the time-temperature-transformation (TTT) diagram for that alloy, not one compromised by surface reactions.

Preserving Surface Integrity

A perfect core grain structure is useless if the surface of the part has been compromised. Vacuum treating ensures the properties of the material are consistent from the surface all the way to the core.

This is critical for components where the surface experiences the highest stress or wear, such as bearings, gears, and cutting tools. The intended hardness and grain structure are preserved right where they are needed most.

Enabling High-Temperature Alloy Processing

Many advanced materials, like high-speed tool steels or nickel-based superalloys, require extremely high solution treating temperatures (often exceeding 1200°C) to dissolve carbides and other alloying elements.

Attempting to reach these temperatures in an atmosphere would result in catastrophic oxidation. A vacuum is the only practical environment to perform these treatments, making it an enabling technology for the highest-performance alloys.

Understanding the Trade-offs

While metallurgically superior for many applications, vacuum heat treatment is not a universal solution. Objectivity requires acknowledging its limitations.

Cost and Complexity

Vacuum furnaces represent a significant capital investment and have higher operating costs than traditional atmospheric furnaces due to energy consumption for the pumps and the use of expensive quenching gases.

Process Cycle Time

While the cooling portion can be very fast, the overall cycle time for a vacuum process can be longer. Time is required to pump the chamber down to the required vacuum level before the heating cycle can even begin.

When It May Be Overkill

For general-purpose carbon steels or applications where surface finish is not a final requirement (e.g., parts that will be heavily machined post-treatment), the benefits of a vacuum may not justify the cost. A simpler controlled atmosphere furnace is often sufficient.

Making the Right Choice for Your Application

Your choice of heat treatment environment should be driven by the material, component complexity, and performance requirements.

- If your primary focus is maximum performance and reliability: For high-strength steels, tool steels, stainless steels, and superalloys, vacuum treatment is the definitive choice for achieving optimal and repeatable properties.

- If your primary focus is minimizing distortion: For intricate, thin-walled, or high-precision components, the uniform heating and controlled gas quenching of a vacuum furnace drastically reduce the risk of warping.

- If your primary focus is cost-effectiveness for non-critical parts: For low-carbon steels or applications where a small amount of scaling is acceptable, a traditional atmospheric furnace is a more economical solution.

Ultimately, selecting a vacuum environment is a decision to prioritize metallurgical precision and part integrity.

Summary Table:

| Aspect | Effect on Grain Structure |

|---|---|

| Environment | Removes oxygen, preventing oxidation and decarburization |

| Temperature | Ensures uniform heating for homogeneous grain formation |

| Cooling | Allows precise control via gas quenching for fine microstructures |

| Applications | Ideal for high-strength steels, tool steels, and superalloys |

Upgrade your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, ensuring optimal grain structure control and enhanced material performance. Contact us today to discuss how we can support your specific applications and drive innovation in your research!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance