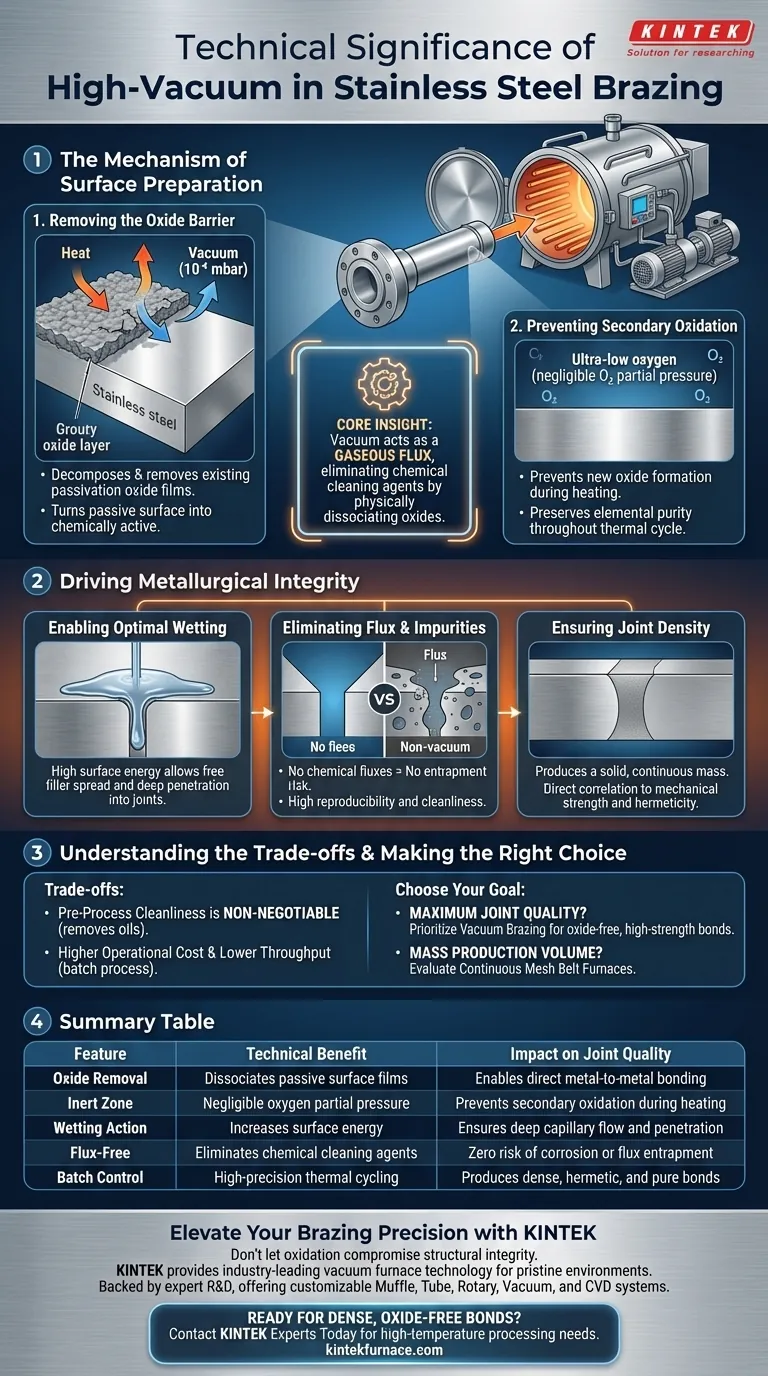

The technical significance of the high-vacuum environment lies in its ability to actively modify the surface chemistry of stainless steel during the heating cycle. By maintaining a vacuum level typically around 10^-6 mbar, the furnace performs two critical functions: it strips away existing passivation oxide films and completely creates an inert zone that prevents secondary oxidation. This pristine, oxide-free surface is the prerequisite for the brazing filler metal to achieve the necessary wetting and spreading required for a structural bond.

Core Insight The vacuum environment acts as a gaseous flux, eliminating the need for chemical cleaning agents by physically dissociating oxides from the steel surface. This ensures the formation of a dense, non-porous metallurgical bond that is chemically pure and structurally superior to joints formed in non-vacuum atmospheres.

The Mechanism of Surface Preparation

Removing the Oxide Barrier

Stainless steel is naturally coated with a passive oxide film that inhibits bonding. The primary function of the high-vacuum environment is to decompose and remove these existing oxide films.

Without this removal, the brazing filler metal would sit on top of the oxide layer rather than bonding with the base metal. The vacuum turns a chemically passive surface into a chemically active one.

Preventing Secondary Oxidation

High-temperature processing usually accelerates oxidation, which ruins the joint. The vacuum environment lowers the partial pressure of oxygen to negligible levels.

This effectively prevents secondary oxidation of both the base stainless steel and the brazing filler metal. It preserves the elemental purity of the materials throughout the thermal cycle.

Driving Metallurgical Integrity

Enabling Optimal Wetting

For a braze to hold, the filler metal must flow capillarily across the joint. This phenomenon, known as wetting, is impossible on dirty or oxidized surfaces.

The clean heating environment ensures the surface energy of the stainless steel is high enough to allow the liquid filler to spread freely. This results in deep penetration into the joint gap.

Eliminating Flux and Impurities

Because the vacuum atmosphere handles oxide removal, chemical fluxes are rendered obsolete. This eliminates the risk of flux entrapment, which can cause corrosion or voids inside the joint.

This results in a process characterized by high reproducibility and cleanliness. It creates a joint free from reactions with environmental impurities.

Ensuring Joint Density

The ultimate output of these factors is a "dense" bond. By removing gases and oxides that could create voids, the vacuum ensures the filler metal solidifies into a solid, continuous mass.

This density is directly correlated to the mechanical strength and hermeticity of the final assembly.

Understanding the Trade-offs

The Requirement for Pre-Process Cleanliness

While the vacuum removes oxides, it cannot handle heavy oils or gross contamination. Thorough pre-cleaning of parts is still a non-negotiable requirement for successful vacuum brazing.

Operational Costs and Throughput

Vacuum furnaces generally represent a higher investment and operating cost compared to continuous mesh belt furnaces. They are batch-process systems, which may offer lower throughput than atmosphere-controlled continuous lines used for mass production.

Making the Right Choice for Your Goal

The vacuum environment is not just about keeping air out; it is an active processing tool for surface engineering.

- If your primary focus is Maximum Joint Quality: Prioritize vacuum brazing to ensure oxide-free, high-strength bonds without the risk of flux inclusion.

- If your primary focus is Mass Production Volume: Evaluate whether continuous mesh belt furnaces with controlled atmospheres can meet your quality specs at a lower cost per unit.

The high-vacuum environment transforms the brazing process from simple joining into a precision metallurgical treatment that guarantees structural reliability.

Summary Table:

| Feature | Technical Benefit | Impact on Joint Quality |

|---|---|---|

| Oxide Removal | Dissociates passive surface films | Enables direct metal-to-metal bonding |

| Inert Zone | Negligible oxygen partial pressure | Prevents secondary oxidation during heating |

| Wetting Action | Increases surface energy | Ensures deep capillary flow and penetration |

| Flux-Free | Eliminates chemical cleaning agents | Zero risk of corrosion or flux entrapment |

| Batch Control | High-precision thermal cycling | Produces dense, hermetic, and pure bonds |

Elevate Your Brazing Precision with KINTEK

Don't let oxidation compromise your structural integrity. KINTEK provides industry-leading vacuum furnace technology designed to deliver the pristine environment required for high-performance stainless steel brazing. Backed by expert R&D and world-class manufacturing, we offer a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific lab or industrial requirements.

Ready to achieve dense, oxide-free metallurgical bonds?

Contact KINTEK Experts Today to discuss your high-temperature processing needs and discover how our advanced furnace solutions can optimize your production quality.

Visual Guide

References

- Kirsten Bobzin, Sophie Vinke. Joining Stainless Steel with a Novel Fe‐Based Amorphous Brazing Foil. DOI: 10.1002/srin.202500141

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the regulatory function of a vacuum drying oven? Master Catalyst Preparation and Distribution Control

- What role does vacuum radiation play in CAP capping? Optimize Ingot Integrity and Material Yield

- How does vacuum sintering increase the strength of sintered parts? Boost Density and Purity for Superior Performance

- What processes can vacuum carburizing furnaces perform? Unlock Versatile Heat Treatment Solutions

- How can rapid cooling (quenching) benefit the process in a vacuum furnace? Boost Efficiency and Material Properties

- What industries benefit from High Vacuum Melting Furnaces? Unlock Purity for Aerospace, Biomedical & More

- What are the technical advantages of using a vacuum drying oven? Protect WC-Co-Ni Powders from Oxidation

- What is the role of insulation materials in a vacuum furnace? Boost Efficiency and Precision in High-Temp Processing