The technical advantage of a vacuum drying oven lies in its ability to separate solvent removal from high thermal exposure. For WC-Co-Ni mixed powders, this specific environment allows alcohol dispersants to evaporate at significantly lower temperatures, preventing the oxidation of chemically active Nickel (Ni) and Cobalt (Co) binders that typically degrade in standard atmospheric drying.

Core Takeaway In cemented carbide production, the presence of oxygen is the enemy of structural integrity. Vacuum drying serves as a protective processing step that removes solvents without overheating the material, ensuring the Nickel and Cobalt binders remain metallic and pure—a critical requirement for achieving proper wetting and high density during the subsequent sintering phase.

Preserving Chemical Integrity

Preventing Binder Oxidation

The primary risk in processing WC-Co-Ni powders is the high reactivity of the metallic binder phase. Nickel (Ni) and Cobalt (Co) are "active metal powders" that readily react with oxygen when heated in a standard atmosphere.

Vacuum drying operates by reducing the environmental pressure, which lowers the boiling point of solvents like alcohol.

This allows the dispersants to volatilize and be removed without subjecting the powder to the high temperatures that trigger rapid oxidation.

Controlling Oxygen Content

maintaining low oxygen content is not merely a preference; it is a chemical necessity for this material system.

If the powder oxidizes during drying, the oxygen remains trapped within the mixture.

This residual oxygen interferes with the material's chemistry downstream, specifically inhibiting the interaction between the carbide particles and the metal binder.

Optimizing Physical Properties

Preventing Agglomeration

High heat often causes fine powders to fuse or clump together, forming hard agglomerates that are difficult to mold.

By facilitating evaporation at lower temperatures, vacuum drying reduces the "liquid bridge forces" that draw particles together.

This preserves a loose, porous powder consistency, ensuring the material remains uniform for the molding and pressing stages.

Deep Pore Solvent Removal

Standard drying often traps moisture or solvents deep within powder clusters due to surface tension and atmospheric pressure.

The negative pressure of a vacuum oven forces these trapped volatiles to expand and escape from within the microstructure.

This ensures the complete removal of potential contaminants like ethanol or water, which could otherwise cause cracking or defects during sintering.

Impact on Sintering and Final Quality

Ensuring Proper Wetting

The success of cemented carbide relies on the liquid binder phase (Co/Ni) flowing around and "wetting" the Tungsten Carbide (WC) particles during sintering.

Oxidation acts as a barrier to this process.

By preventing surface oxides during drying, the vacuum process ensures the binder retains high surface activity, allowing it to wet the carbide particles completely.

Achieving Maximum Density

The ultimate goal of using WC-Co-Ni is to create a dense, hard material.

Poor wetting caused by prior oxidation leads to porosity and voids in the final product.

Therefore, the use of a vacuum drying oven is directly correlated to achieving the final density and mechanical strength required for high-performance cemented carbide tools.

Understanding the Trade-offs

Equipment vs. Quality

While vacuum drying is technically superior for active metals, it introduces higher equipment costs and complexity compared to standard convection ovens.

However, for WC-Co-Ni mixtures, this is rarely a choice of convenience. The chemical sensitivity of Cobalt and Nickel makes vacuum processing a technical requirement rather than an optional upgrade.

Using standard drying methods for these specific materials would likely result in inferior metallurgy that cannot be corrected in later processing steps.

Making the Right Choice for Your Goal

To ensure the integrity of your cemented carbide production, consider the following regarding your processing equipment:

- If your primary focus is Final Material Density: You must use vacuum drying to prevent oxidation, as oxide layers on Co/Ni particles will inhibit densification during sintering.

- If your primary focus is Powder Flowability: Vacuum drying is recommended to prevent the formation of hard agglomerates, ensuring the powder fills molds evenly.

- If your primary focus is Solvent Recovery: Vacuum drying allows for safer, low-temperature capture of volatile alcohol dispersants compared to venting hot ovens.

Ultimately, vacuum drying is the only reliable method to dehydrate WC-Co-Ni powders without sacrificing the chemical activity of the binder phase.

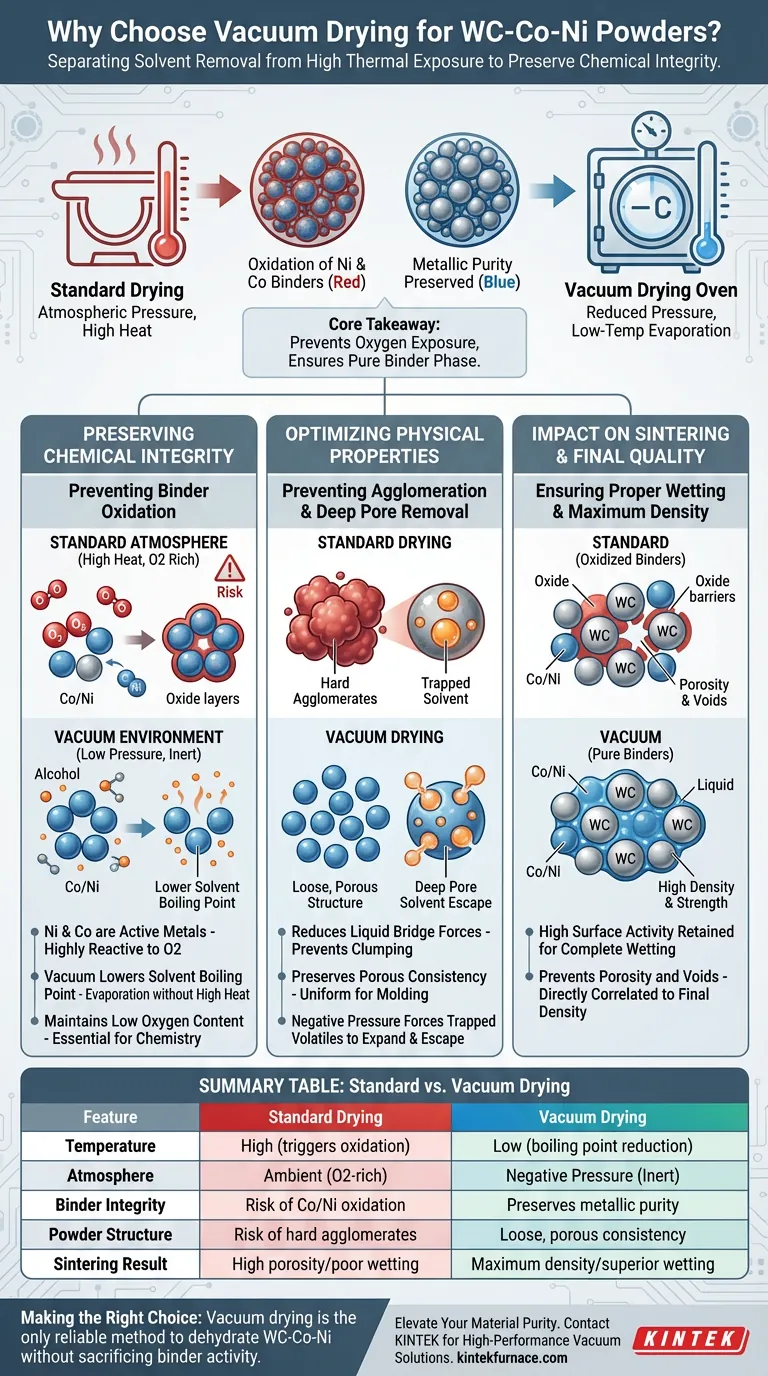

Summary Table:

| Feature | Standard Drying Method | Vacuum Drying Oven |

|---|---|---|

| Temperature | High (triggers oxidation) | Low (boiling point reduction) |

| Atmosphere | Ambient (oxygen-rich) | Negative Pressure (inert/protective) |

| Binder Integrity | Risk of Co/Ni oxidation | Preserves metallic purity |

| Powder Structure | Risk of hard agglomerates | Loose, porous consistency |

| Sintering Result | High porosity/poor wetting | Maximum density/superior wetting |

Elevate Your Material Purity with KINTEK

Don’t let oxidation compromise the structural integrity of your WC-Co-Ni mixtures. Backed by expert R&D and precision manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, and CVD systems—all fully customizable to meet your unique lab and industrial requirements.

Our specialized vacuum drying solutions ensure the chemical activity of your binders remains intact, facilitating perfect wetting and maximum density in every batch.

Ready to optimize your drying process?

Contact us today to discuss your project requirements!

Visual Guide

References

- Effect of ni content on mechanical properties and corrosion resistance of WC-Co-Ni cemented carbides. DOI: 10.2298/pac2502121x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What types of metallurgical processes can vacuum furnaces perform? Achieve Purity and Precision in Metal Treatment

- Why is a vacuum oven utilized for g-C3N4/CdS precursor drying? Protect Nano-Architecture & Prevent Oxidation

- What are the advantages of using vacuum furnaces for sintering applications? Achieve Superior Metallurgical Control

- Why is it necessary to maintain a high vacuum for PrVSb3 single crystal preparation? Ensure Purity and Stoichiometry

- Why is argon preferred over nitrogen in certain applications? Ensure Purity in High-Temp Processes

- What are common insulation materials used in vacuum furnaces? Optimize Heat Control for Your Lab

- What role does a vacuum system play in Vanadium-Nitrogen alloy preparation? Boost Chemical Efficiency and Yield

- What are the overall benefits of using vacuum heat treatment furnaces? Achieve Superior Material Purity and Performance