For any high-stakes sintering application, a vacuum furnace provides unparalleled control over the final product's metallurgical properties. This technology ensures superior part quality by creating an extremely pure, highly controlled thermal environment. Key advantages include the complete elimination of atmospheric contamination, exceptional temperature uniformity, and a high degree of process automation for perfect repeatability.

The decision to use a vacuum furnace is an investment in process integrity. While other methods exist, vacuum sintering offers a unique combination of atmospheric purity and precise thermal control that is essential for producing high-performance, defect-free components from advanced materials.

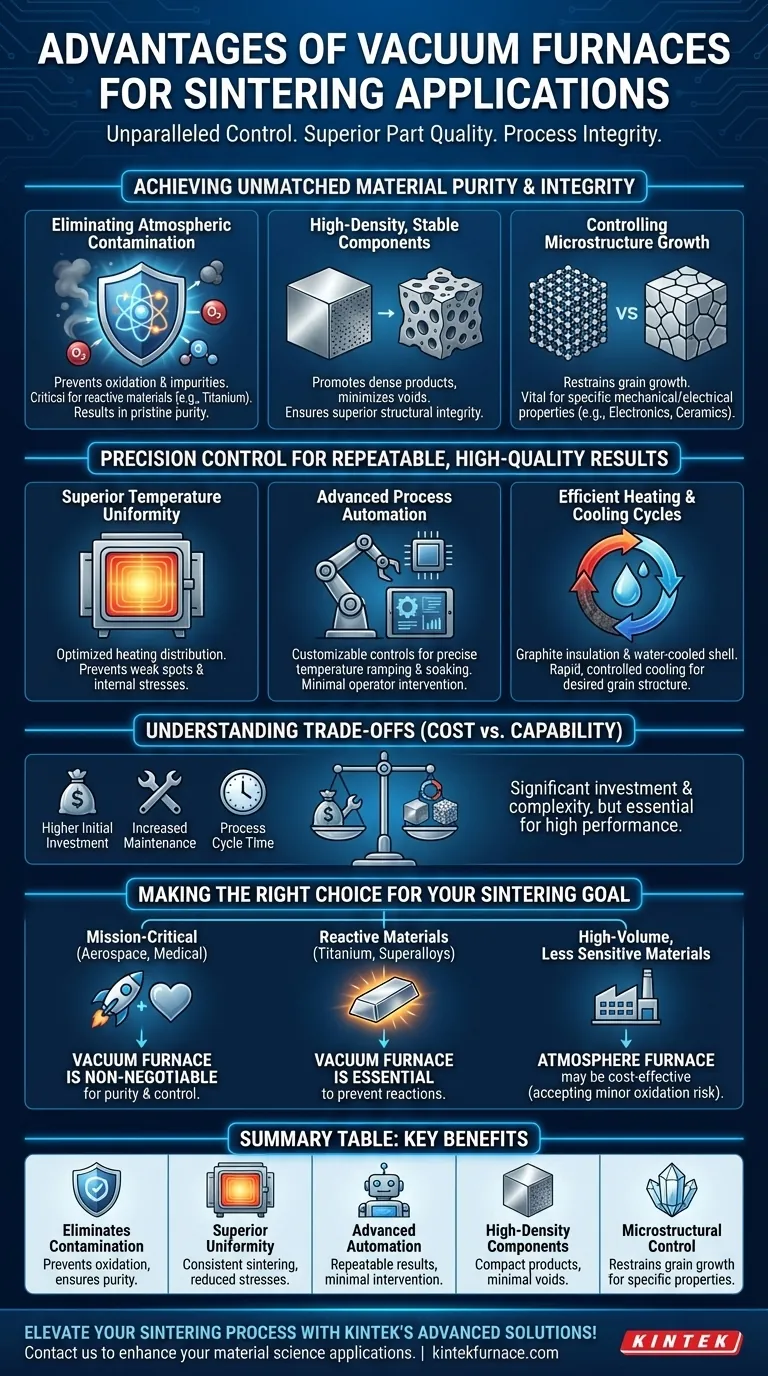

Achieving Unmatched Material Purity and Integrity

The primary driver for using a vacuum furnace is to control the component's environment at a molecular level. This prevents unwanted chemical reactions that compromise the material's final properties.

Eliminating Atmospheric Contamination

By removing air and other gases, a vacuum furnace eliminates the risk of oxidation and contamination. This is critical for reactive materials like titanium or for applications where even trace impurities can lead to component failure. The result is a finished part with pristine material purity.

Producing High-Density, Stable Components

Sintering in a vacuum promotes the creation of highly compacted and dense products. This process minimizes internal voids and prevents the deformation that can occur in less-controlled atmospheres, ensuring superior structural integrity.

Controlling Microstructure Growth

For advanced applications involving nanomaterials, a vacuum environment can restrain the growth of crystal grains. This level of microstructural control is vital for achieving specific mechanical or electrical properties required in industries like electronics and advanced ceramics.

Precision Control for Repeatable, High-Quality Results

Beyond purity, vacuum furnaces offer a level of thermal and process control that ensures every part in a batch, and every batch over time, meets the exact same specifications.

Superior Temperature Uniformity

These furnaces are engineered with optimized heating element distribution and advanced insulation. This design guarantees a highly uniform temperature throughout the heating chamber, which is crucial for consistent sintering and preventing weak spots or internal stresses in the component.

Advanced Process Automation

Modern vacuum furnaces are highly automated systems. They feature customizable controls for precise temperature ramping and soaking, along with safety interlocks and alarms for over-temperature or system issues. This ensures the sintering cycle is executed perfectly every time with minimal operator intervention.

Efficient Heating and Cooling Cycles

The use of high-performance graphite-based insulation minimizes heat loss, while features like a double-layer water-cooled shell enable rapid and controlled cooling. This thermal efficiency not only reduces energy consumption but also allows for greater control over the material’s final grain structure.

Understanding the Trade-offs: Cost vs. Capability

While the advantages are significant, adopting vacuum technology requires a clear understanding of its associated costs and operational demands.

Higher Initial Investment

Vacuum furnaces represent a significant capital expenditure compared to conventional atmosphere furnaces. The cost includes the furnace itself, along with the complex vacuum pumps, seals, and control systems required for its operation.

Increased Maintenance Complexity

The systems that create and maintain the vacuum, particularly pumps and chamber seals, demand specialized and regular maintenance. A failure to maintain a hard vacuum will negate the primary benefits of the technology.

Process Cycle Time

Pulling a deep vacuum is not instantaneous. The evacuation phase can add time to the overall process cycle compared to simply purging a chamber with an inert gas. This must be factored into production throughput calculations.

Making the Right Choice for Your Sintering Goal

Selecting the right furnace technology depends entirely on the required performance and value of your final component. Use these points as a guide for your decision.

- If your primary focus is producing mission-critical components (aerospace, medical): A vacuum furnace is non-negotiable for its purity and process control.

- If your primary focus is working with reactive materials (titanium, superalloys): The inert environment of a vacuum furnace is essential for preventing unwanted reactions and achieving desired material properties.

- If your primary focus is high-volume production of less sensitive materials: A traditional atmosphere furnace might offer a more cost-effective solution, provided you can accept the risk of minor oxidation or contamination.

Ultimately, investing in a vacuum furnace is a strategic decision to master the material science of your components.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Eliminates Contamination | Prevents oxidation and ensures material purity for reactive materials like titanium |

| Superior Temperature Uniformity | Optimized heating for consistent sintering and reduced internal stresses |

| Advanced Process Automation | Customizable controls for repeatable results with minimal operator intervention |

| High-Density Components | Promotes compact, dense products with minimal voids and deformation |

| Microstructural Control | Restrains crystal grain growth for specific mechanical/electrical properties |

Elevate your sintering process with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-performance options like Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, and more. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering unmatched purity, repeatability, and efficiency for industries such as aerospace and medical. Contact us today to discuss how we can enhance your material science applications!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density